-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In industrial applications, the efficiency and reliability of fluid control systems are paramount, and one crucial component that plays a vital role in this is the Carbon Steel Ball Valve. According to a report by Global Market Insights, the ball valve market is projected to surpass USD 15 billion by 2027, with carbon steel variants gaining significant traction due to their robustness, durability, and cost-effectiveness. The ability to manage high pressures and temperatures while maintaining a tight seal makes Carbon Steel Ball Valves a preferred choice across various sectors, including oil and gas, chemical processing, and water treatment. As industries continue to emphasize operational efficiency and sustainability, adopting top strategies for maximizing the performance of these valves can lead to significant cost savings and enhanced productivity. Understanding the intricacies of these valves, including their designs, advantages, and maintenance practices, is essential for engineers and decision-makers aiming to optimize their industrial processes.

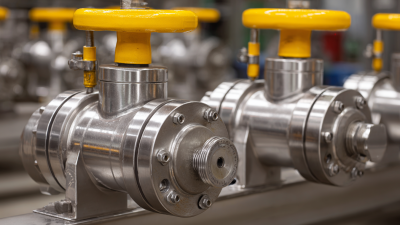

Carbon steel ball valves play a crucial role in various industrial applications due to their durability and efficiency. Understanding the basics of these valves is essential for maximizing their potential in operational settings. Carbon steel, known for its strength and resistance to wear, makes these valves a reliable choice for handling fluids under high pressure and temperature. The spherical design of the valve allows for quick, quarter-turn operation, providing precise control over fluid flow while minimizing turbulence and pressure drop.

In industrial environments, proper selection and maintenance of carbon steel ball valves are vital to ensure optimal performance. Factors such as the type of fluid handled, temperature, and pressure conditions should inform the choice of valve design and materials. Routine inspections and timely maintenance help prevent issues such as leakage or corrosion, further enhancing efficiency. By prioritizing the right installations and upkeep, industries can leverage carbon steel ball valves to achieve smoother operations and ultimately improve productivity.

Carbon steel ball valves play a crucial role in enhancing operational efficiency across various industrial sectors. One of the key features that contribute to their effectiveness is their design, which allows for minimal pressure drop and turbulence during fluid flow. According to a report by the American Society of Mechanical Engineers (ASME), valves that include a full-port design can reduce pressure loss by up to 30% compared to other valve types. This reduction not only promotes energy savings but also ensures a smoother operation, ultimately leading to faster response times in critical processes.

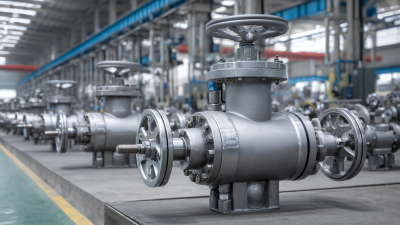

Another significant attribute of carbon steel ball valves is their durability and resistance to wear and tear. The 2022 Global Valve Market report indicated that industries utilizing high-quality carbon steel valves experienced a 15% increase in longevity compared to those using standard materials. Enhanced sealing capabilities provided by modern ball valve designs further fortify operational reliability, preventing leaks that can lead to costly downtimes. With these impressive attributes, carbon steel ball valves are essential in optimizing industrial processes while minimizing maintenance costs and improving overall workflow efficiency.

When it comes to installing carbon steel ball valves for optimal performance, there are several best practices to consider. First, it's crucial to select the right size of the valve based on the specific application requirements. Oversized valves can decrease flow efficiency, while undersized ones can lead to pressure drops. Proper sizing ensures that the valve operates at its peak capacity, ensuring seamless functionality within the system.

Another essential aspect of installation is ensuring that the valve is aligned correctly within the pipeline. Misalignment can cause excessive wear and tear, leading to premature failure. Utilizing proper mounting techniques and securing the valve to the pipeline with the appropriate hardware is vital.

Additionally, it's important to inspect the valve and connection points for any contaminants or debris prior to installation, as this can affect the integrity and performance of the valve over time. By following these best practices, users can enhance the efficiency and longevity of carbon steel ball valves in industrial applications.

Proper maintenance of carbon steel ball valves is crucial for ensuring longevity and efficiency in industrial applications. Regular inspection and monitoring can identify wear and potential issues before they escalate, allowing for timely repairs or replacements. Implementing a preventive maintenance schedule that includes checking seals, gaskets, and the valve body for corrosion can significantly enhance the operational lifespan of these components.

Additionally, understanding the impact of operating conditions is essential. Factors such as temperature, pressure, and the type of fluid being handled can all contribute to the wear and tear of the valves. By utilizing advancements in materials and design, operators can reduce stress on critical components, extending their life and improving overall system performance. Regularly upgrading to newer technologies that incorporate better materials and design can lead to significant cost savings in the long run, as they effectively shift wear to more easily replaceable parts.

| Maintenance Strategy | Frequency | Expected Benefit | Recommended Tools |

|---|---|---|---|

| Visual Inspection | Monthly | Identify leaks or wear | Inspection Mirror, Flashlight |

| Lubrication | Quarterly | Reduce friction and wear | Grease Gun, Lubricants |

| Actuator Calibration | Annually | Ensure proper operation | Calibration Tools |

| Seal Replacement | Every 2-3 years | Prevent leaks | Seal Kits, Wrenches |

| Cleaning | Biannual | Remove debris and buildup | Cleaning Solvent, Brushes |

When utilizing carbon steel ball valves in industrial applications, it's crucial to navigate common pitfalls to maximize operational efficiency. One major issue is the improper selection of valve size and type, which can lead to significant pressure drops and energy losses. According to a study by the American Society of Mechanical Engineers (ASME), optimal valve sizing can improve flow rates by as much as 25%, directly impacting the system's overall performance and energy costs.

Another critical pitfall is neglecting routine maintenance and inspection. A report from the International Society of Automation (ISA) indicates that nearly 70% of valve failures are due to inadequate maintenance practices. Regular inspections can help identify wear and tear, ensuring that carbon steel ball valves operate effectively and reducing unplanned downtime. Additionally, the use of high-quality lubricants and seals can enhance the lifespan of these valves, contributing to a more sustainable industrial process. By being aware of these common issues and addressing them proactively, industries can leverage carbon steel ball valves to their full potential, promoting both efficiency and reliability.