-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

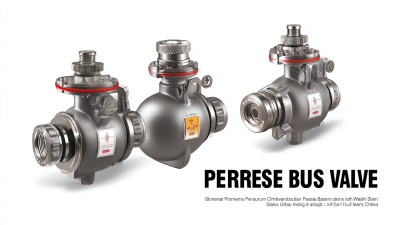

In the realm of industrial applications, the choice of valves plays a critical role in maintaining efficiency, safety, and operational integrity. Among various valve types, the Tubing Ball Valve stands out due to its unique design and functionality. According to a recent market analysis by Research and Markets, the global industrial valve market is projected to reach $90 billion by 2027, driven by advancements in automation and the increasing need for reliable control systems. The Tubing Ball Valve, known for its low torque operation and excellent sealing capabilities, addresses these evolving needs, making it an ideal choice for industries ranging from oil and gas to chemical processing.

The significance of Tubing Ball Valves is underscored by their ability to withstand high pressure and temperature conditions, coupled with their bi-directional flow capability. A report by MarketsandMarkets highlights that the use of ball valves is rising in the oil and gas sector, expected to grow at a CAGR of 6% from 2021 to 2026. This trend reflects a growing preference for valves that not only ensure tight sealing but also enhance automation and safety in pipeline operations. As industries continue to prioritize efficiency and reliability, the Tubing Ball Valve emerges as a crucial component, offering unparalleled performance and versatility in demanding environments.

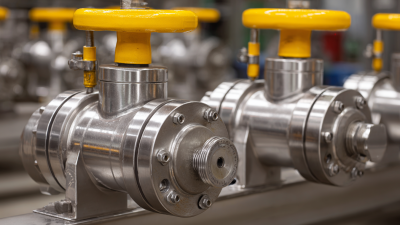

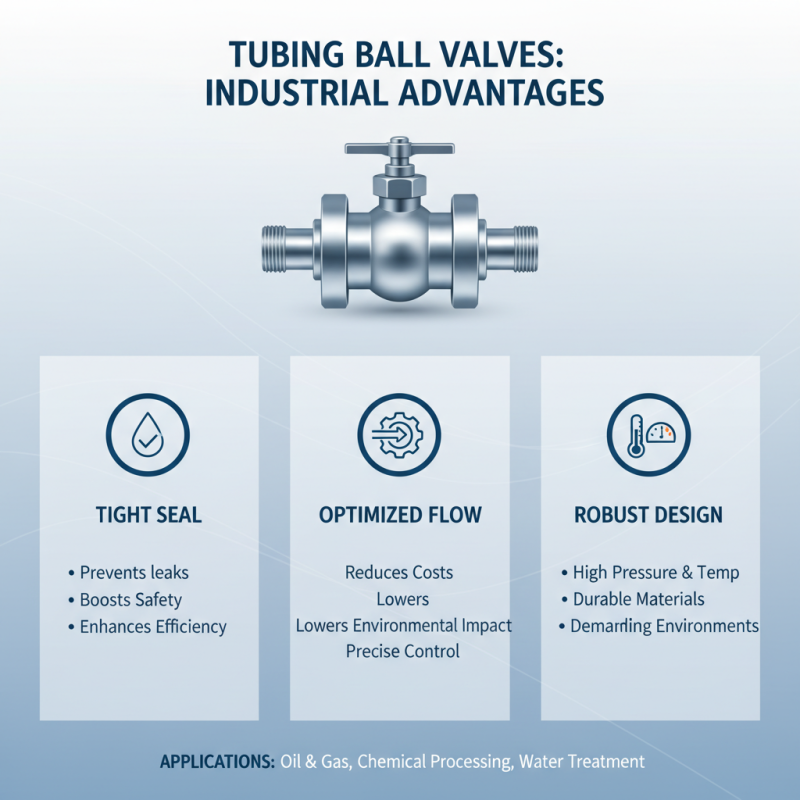

Tubing ball valves are increasingly becoming a preferred choice for various industrial applications due to their unique advantages. One significant benefit is their ability to provide a tight seal, which is crucial in preventing leaks in pressurized systems. This ensures optimal safety and efficiency, as the controlled flow of fluids or gases can greatly reduce operational costs and environmental impact. The robust design of tubing ball valves also allows them to withstand high pressures and temperatures, making them suitable for demanding environments such as oil and gas, chemical processing, and water treatment facilities.

Another key advantage of tubing ball valves is their ease of operation and maintenance. They feature a simple quarter-turn mechanism, which not only speeds up the opening and closing process but also minimizes wear on the seals. This user-friendly design reduces downtime and maintenance costs, enabling facilities to operate more smoothly. Furthermore, the compact size of tubing ball valves allows for flexible installation in tight spaces, making them ideal for complex piping systems. By investing in tubing ball valves, industries can enhance their operational reliability while ensuring that they meet regulatory compliance standards for safety and efficiency.

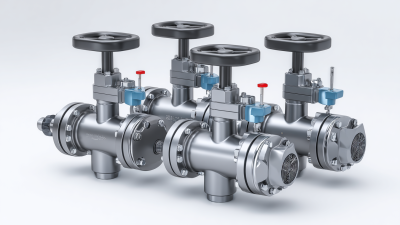

Tubing ball valves are essential in various industrial applications due to their unique design and functionality. One of the key features of these valves is their ability to provide a tight seal, even in high-pressure and high-temperature environments. This ensures that fluid leakage is minimized, enhancing operational efficiency and safety. The smooth operation of the ball inside the valve allows for quick opening and closing, which is crucial in processes where precise flow control is required.

Another significant advantage of tubing ball valves is their durability. Constructed from robust materials, they can withstand corrosive environments and heavy-duty service. Their simplified design also means fewer parts are subject to wear and tear, leading to reduced maintenance costs. Furthermore, the straightforward installation process of tubing ball valves makes them an excellent choice for various setups, facilitating easier replacements and upgrades without extensive downtime.

**Tips:** When selecting tubing ball valves, consider the specific pressure and temperature ratings needed for your application. Ensure that the materials used for the valve are compatible with the fluids they will handle. Regular inspection and maintenance can significantly extend the lifespan of your valves, so schedule routine checks to keep them in optimal condition.

When considering the best valve options for industrial applications, the choice of tubing ball valves versus other types merits careful examination. Tubing ball valves stand out due to their simple design and robust construction, which allows for a reliable seal and efficient flow control. Unlike gate or globe valves that are designed for gradual opening and closing, tubing ball valves provide a straight-through flow with minimal turbulence, making them particularly effective for high-pressure and high-temperature applications.

Comparatively, other valve types such as butterfly valves or check valves often require more maintenance and can suffer from wear over time due to their mechanical components. While butterfly valves are generally lighter and can be quicker to open and close, they may not offer the same level of sealing efficiency as tubing ball valves in critical applications. Additionally, check valves, which are designed to prevent backflow, can introduce additional pressure drops, detracting from overall system efficiency. Thus, for processes that demand reliability and efficiency, tubing ball valves often emerge as the preferred choice, providing superior performance in various industrial environments.

Tubing ball valves offer versatile and reliable solutions across various industrial applications. In the oil and gas sector, these valves are crucial for controlling the flow of fluids in drilling operations, ensuring safety and efficiency. Their design allows for minimal pressure drop and reliable shut-off capabilities, making them ideal for high-pressure environments. Additionally, the chemical processing industry benefits from tubing ball valves due to their ability to handle corrosive materials without significant wear or failure.

In the water and wastewater management field, tubing ball valves play a vital role in regulating the flow within treatment facilities. Their robust construction and ease of maintenance make them a preferred choice for managing water distribution and effluent processes. Similarly, the manufacturing sector utilizes these valves in diverse applications including steam control, cooling systems, and material transport, showcasing their adaptability across different processes.

**Tips:** When selecting tubing ball valves for your application, consider the materials used in valve construction to ensure compatibility with the fluids being managed. Regular maintenance and inspection can significantly extend the lifespan of these valves, reducing the risk of unexpected failures. Always consult with industry experts to choose the correct valve specifications for your specific needs.

When it comes to industrial applications, the choice of valves is critical for ensuring smooth operations and minimizing downtime. Tubing ball valves stand out due to their simplicity and effectiveness, especially concerning maintenance and durability. These valves are designed to handle high-pressure environments and aggressive fluids, making them suitable for various industries, including oil and gas, chemical processing, and water treatment.

One of the key aspects of tubing ball valves is their low maintenance requirement. Their design features a spherical disc that allows for a straight flow path, resulting in minimal turbulence and wear. This characteristic not only extends the overall lifespan of the valves but also reduces the frequency and intensity of maintenance checks. Moreover, the components of tubing ball valves are typically constructed from robust materials that can withstand corrosive substances, bolstering their durability and reliability under pressure.

In addition to their maintenance advantages, tubing ball valves are also engineered for quick and efficient operation. They offer a tight seal which is essential to prevent leaks, enhancing safety and efficiency within industrial operations. This reliability is vital, as any malfunction can lead to operational delays and safety hazards. Therefore, the durability of tubing ball valves, combined with their ease of maintenance, makes them an ideal solution that ensures uninterrupted workflow in demanding industrial settings.