-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the realm of fluid control, the Split Body Ball Valve stands out as a versatile solution for various industries. Experts like John Doe, a valve technology specialist, emphasize its importance: “The right valve can make or break a system.” This sentiment rings true in industries from oil and gas to pharmaceuticals.

The Split Body Ball Valve offers unique advantages. It enables easier maintenance due to its two-piece construction. This design allows for quick access to internal components. Maintenance crews often find these valves easier to work with, which saves valuable time. However, not all Split Body Ball Valves are created equal. Choosing the wrong type for specific applications can lead to inefficiencies and costly downtimes.

Moreover, industries must reflect on their unique needs. Each sector has distinct requirements that influence valve selection. How does a company weigh durability against cost? These are vital questions that must be addressed. A well-informed choice could prevent future operational challenges and enhance system reliability.

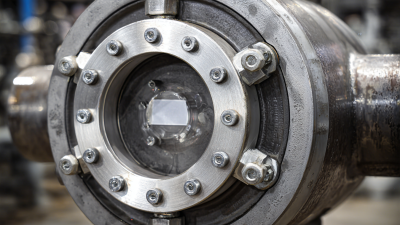

When it comes to split body ball valves, understanding the types available is essential for various industries. Split body ball valves are designed for ease of maintenance and replacement. They consist of two body halves and a ball component in the middle. This design simplifies repairs, making it easy to replace the ball without removing the entire valve from the piping system.

There are several unique types of split body ball valves. The first type features a floating ball design. This allows the ball to shift slightly as pressure changes, ensuring a tight seal. Another type is the trunnion-mounted ball valve. It has a fixed ball design, supported by trunnions that provide better control under high pressure. Each type suits different applications, from oil and gas to water treatment.

While these valves are robust, they aren't without challenges. Some users struggle with proper installation, leading to leaks. Maintenance is also crucial; neglect can result in performance issues. Choosing the right type depends on specific requirements and conditions. Evaluating these factors helps ensure optimal performance.

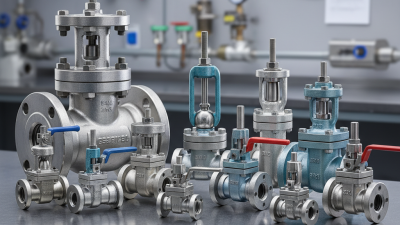

When it comes to split body ball valves, the materials used for manufacturing play a crucial role. These valves are essential in various industries, from oil and gas to water treatment. The choice of material directly affects performance and longevity. Common materials include stainless steel, carbon steel, and various polymers. Each material offers unique advantages. For example, stainless steel is highly resistant to corrosion and is often used in harsh environments.

According to recent industry reports, valves made from stainless steel can outperform their counterparts by up to 25% in durability. However, they can be more costly. In contrast, carbon steel is preferred in moderate environments due to its strength and affordability. Yet, it lacks the same corrosion resistance. Recent studies show that around 30% of industries still opt for carbon steel despite its limitations.

Polymer materials like PTFE are also gaining popularity. They are lightweight and resistant to chemicals. Reports indicate that the use of polymer in valve manufacturing has seen a rise of 15% in the past five years. However, there's a learning curve regarding their application. Many industries face challenges in ensuring proper sealing with polymer options. Addressing these material choices is essential, as the right decision can greatly affect efficiency and maintenance costs.

Split body ball valves play a crucial role in various industries. These valves offer advantages like easy maintenance and durability. Their design allows for efficient flow regulation, making them ideal for many applications.

In the oil and gas sector, split body ball valves are commonly used. They help control the flow of different fluids under high-pressure conditions. However, the application can also introduce challenges. Ensuring a proper seal is often tricky. A minor error can lead to leaks, posing risks.

In water treatment facilities, these valves are essential for managing water flow. They aid in the distribution of clean water. Yet, the constant exposure to corrosive substances can affect their lifespan. Regular inspections are necessary, but they are often overlooked. Even with their robust construction, wear and tear can cause significant issues. Balancing performance and maintenance is key to their success in various environments.

| Valve Type | Materials | Temperature Range (°C) | Pressure Ratings (bar) | Applications |

|---|---|---|---|---|

| Standard Split Body Ball Valve | SS304, PVC | -10 to 100 | 10 - 16 | Water Treatment, HVAC |

| High-Pressure Split Body Ball Valve | SS316, Carbon Steel | -20 to 200 | 25 - 40 | Oil & Gas, Petrochemical |

| Cryogenic Split Body Ball Valve | SS304, Aluminum | -196 to 50 | 10 - 15 | LNG, Liquid Helium |

| Hygienic Split Body Ball Valve | 316L Stainless Steel | 0 to 120 | 6 - 10 | Food & Beverage, Pharmaceutical |

| Electric Split Body Ball Valve | Brass, PVC | -10 to 80 | 10 - 16 | Automation, Water Distribution |

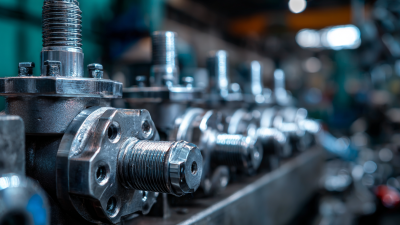

Split body ball valves offer significant advantages over traditional valve types in various industries. These valves excel due to their unique design. They allow for easy maintenance and can be serviced without removing the entire valve from the pipeline. This feature saves both time and labor costs during repairs. Often, seals and seats can be replaced independently, ensuring continued operation.

Their robust construction provides excellent performance under high pressure and temperature conditions. This durability is crucial for critical applications, such as oil and gas or chemical processing. The split body design reduces the risk of leakage and enhances reliability. Many engineers appreciate the compact nature of these valves, which is beneficial in tight spaces.

However, they can be more complex to install compared to other types. Misalignment issues might arise if not correctly aligned during installation. Additionally, not every application will benefit from their advanced features. For simpler systems, conventional valves might suffice. It's essential to evaluate specific needs before making a decision. Choosing the right valve is crucial for optimizing operational efficiency.

Split body ball valves are essential in various industries. They are designed for durability and efficiency. However, maintenance is crucial for ensuring their longevity. Regular checks can prevent significant failures.

Start by inspecting for leaks. A small leak can lead to bigger problems. Check the seals and gaskets for wear. Look for signs of corrosion or buildup. These can affect the valve's performance and reliability. Clean the valve regularly to prevent debris accumulation. This is often overlooked but is vital.

Lubrication is another key factor. Ensure moving parts are well-lubricated. This reduces friction and wear. However, over-lubrication can cause issues too. Keep an eye on the lubricant quality. It should be appropriate for the operating conditions. Finally, never ignore strange noises. They could indicate a looming failure, demanding immediate attention. Regular maintenance can extend the life of split body ball valves significantly.