-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

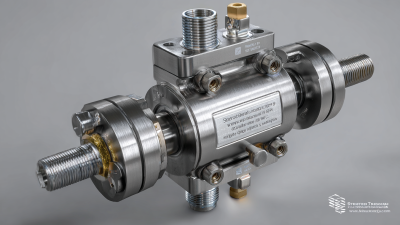

In the evolving world of industrial applications, understanding Metal Seated Ball Valves is crucial. These valves play a significant role in various industries, providing reliable solutions for fluid control. Metal Seated Ball Valves are known for their durability and resistance to high temperatures and pressures. Their robust construction makes them ideal for harsh environments.

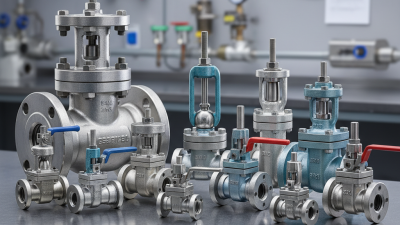

Choosing the right Metal Seated Ball Valve requires careful consideration. Factors include material compatibility, pressure ratings, and operational requirements. Potential users often overlook the importance of these details. Ignoring specifications can lead to operational failures. Therefore, it is essential to gather all necessary information before making a decision.

As industries demand greater efficiency, the role of Metal Seated Ball Valves becomes even more critical. Innovations in valve design are continually emerging, promising improved performance. However, navigating this landscape requires ongoing education. Users must remain informed about new technologies and trends to optimize their operations.

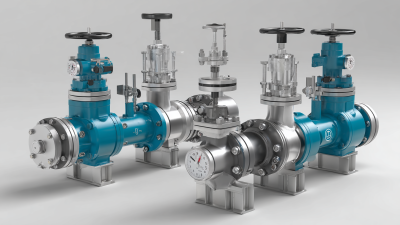

Metal seated ball valves are essential components in various industrial applications. Their robust design makes them suitable for handling high temperatures and pressures. These valves often find use in industries like oil and gas, power generation, and chemical processing. They are known for their durability and reliability.

The metal seat provides a strong barrier against wear and corrosion. This feature significantly extends the valve’s lifespan compared to standard soft seated options. Operators often appreciate how quickly these valves can be repaired. However, the installation requires detailed attention. Improper setup can lead to severe leakage or damage.

In some environments, metal seated ball valves may not completely seal off the flow. This limitation can enhance the need for regular maintenance checks. Users should not overlook this aspect when making a choice. Observing their performance can reveal insights into potential improvements in operations. While metal seated ball valves have notable advantages, they also need careful consideration for optimal use.

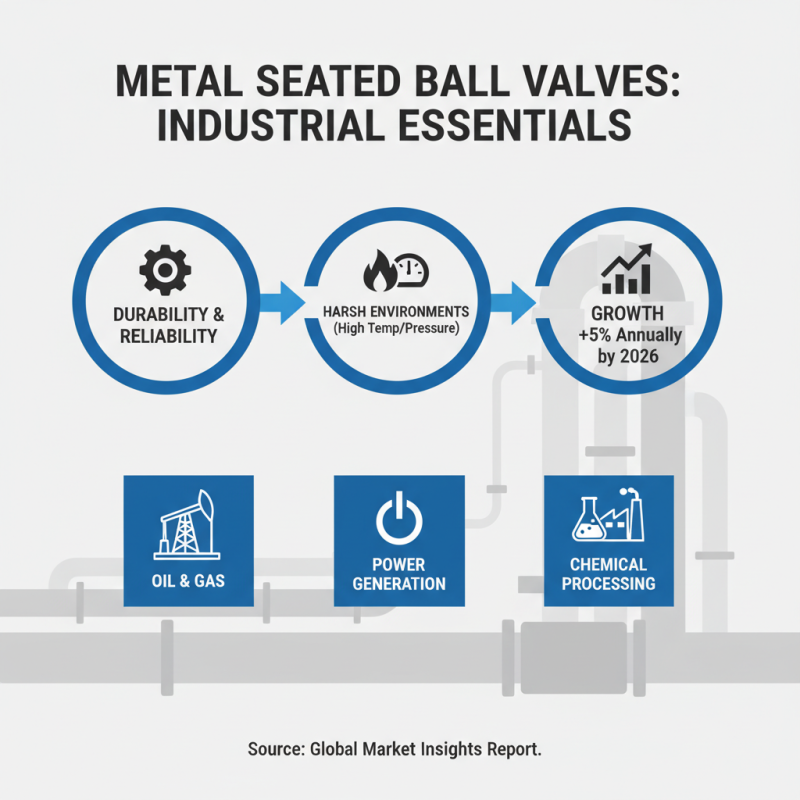

This chart illustrates the distribution of applications for metal seated ball valves in various industries for 2026. The oil and gas industry takes the largest share, followed by water treatment and the chemical industry.

Metal seated ball valves have gained popularity in various industrial applications due to their durability and reliability. These valves are designed to handle harsh environments, including high temperatures and pressures. According to a report from the Global Market Insights, the demand for metal seated ball valves is projected to grow by over 5% annually through 2026. This is indicative of their essential role in sectors like oil and gas, power generation, and chemical processing.

One key advantage of metal seated ball valves is their resistance to wear and tear. Unlike soft seated valves, metal seated options can endure abrasive media without compromising performance. Their lifespan often surpasses that of traditional valves, making them a cost-effective choice in the long run. Furthermore, they are less prone to leakage, which is crucial for maintaining system integrity in demanding applications. However, some users report difficulty in achieving a perfect seal under all conditions. This is a point for reflection in design improvements.

Another notable benefit is the versatility of metal seated ball valves. They are suitable for a wide range of fluids, from liquids to gases. This adaptability has led to increased usage across various industries. Interestingly, some studies suggest that about 15% of users experience challenges with installation and maintenance. This indicates a need for better training and support. Balancing advantages with these challenges is essential for optimal implementation.

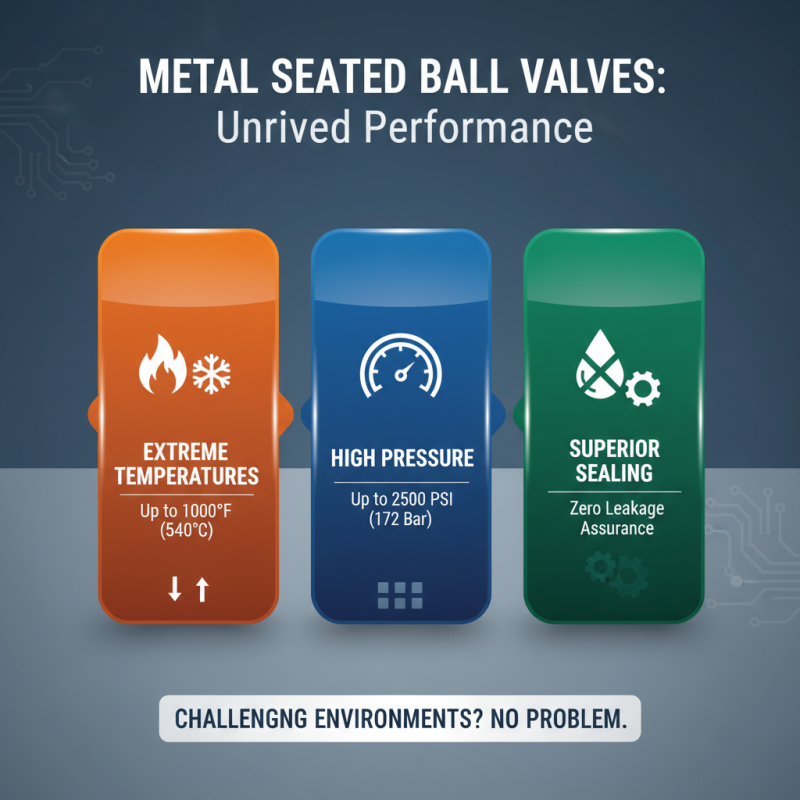

Metal seated ball valves are gaining popularity in various industrial applications. These valves offer exceptional performance characteristics that make them suitable for challenging environments. Their ability to withstand extreme temperatures and pressures sets them apart. Additionally, they provide excellent sealing capabilities, ensuring minimal leakage.

One of the key advantages is their durability. Metal seats can endure abrasive materials and corrosive substances, which are common in many industries. However, the initial cost can be more than standard options. Users must weigh this against the long-term benefits. It’s crucial to understand the maintenance requirements as well. Regular inspections and potential adjustments might be needed to ensure optimum performance.

Another aspect worth mentioning is the adaptability of these valves. They can be customized for specific applications. This flexibility can lead to improvements in efficiency. Yet, one should consider the skill level required for installation. Inadequate installation can lead to performance issues down the line. Careful planning and training are essential to avoid these pitfalls.

When selecting metal seated ball valves, there are key considerations to keep in mind. The material of the valve is crucial. Metals such as stainless steel or carbon steel offer durability. However, always consider the specific application. Some environments may be more corrosive than others. Understanding the working conditions can help you choose the right material.

Tip: Always assess the temperature and pressure ratings. These factors play a vital role in a valve’s performance. A valve rated for high temperatures may not perform well under lower pressure. Ensure compatibility for optimal functionality.

Another aspect to consider is the valve size and connection type. Measure precisely before making a purchase. An ill-fitting valve can lead to leaks or failures. Also, evaluate whether you need a full-port or reduced-port valve. A full-port valve offers better flow but may not fit every application.

Tip: Review installation requirements thoroughly. Improper installation can lead to significant issues down the line. Investing time in the selection and installation process can prevent future headaches.

| Feature | Description | Importance |

|---|---|---|

| Material | Common materials include stainless steel, carbon steel, and alloys to withstand high temperatures and pressures. | Essential for durability and compatibility with fluid types. |

| Pressure Rating | Indicates the maximum working pressure the valve can handle, often rated in PSI or bar. | Crucial for ensuring safe operation within system parameters. |

| Temperature Range | Characterizes the operational temperature limits for the valve, from cryogenic to high temperatures. | Important for applications involving extreme conditions to prevent failure. |

| Seat Design | Metal seated designs allow for better performance in high-temperature and high-pressure applications. | Critical for sealing capability and longevity. |

| Connection Type | Styles include threaded, flanged, and welded connections, impacting installation and maintenance. | Significant for the integration into existing piping systems. |

| End User Applications | Used in oil and gas, chemical processing, power generation, and wastewater management industries. | Determines the type of valve required based on application needs. |

| Certification | Valves may require specific certifications (e.g., API, ISO) depending on industry regulations. | Ensures compliance with safety and performance standards. |

In 2026, the landscape of metal seated ball valves is evolving. Innovations focus on durability and efficiency. New materials and coatings are being researched. These advancements aim to enhance the lifespan of valves in harsh environments. Corrosion resistance and heat tolerance are crucial. Manufacturers are exploring advanced ceramics and composite materials. These might replace traditional metals in specific applications.

Future trends include smart technology integration. Sensors can monitor valve conditions in real time. This leads to proactive maintenance. Predictive analytics could minimize downtime. However, challenges exist. Cost implications of these technologies may deter some users. There’s also a need for training. Workers must learn how to manage these innovations effectively.

Sustainability is another important theme. Eco-friendly practices are gaining traction in valve production. This includes reducing waste and energy consumption. However, finding the right balance between performance and environmental impact is challenging. The industry must reflect on how to innovate responsibly.