-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

Duplex Ball Valves are critical in various industrial applications due to their durability and performance. According to John Smith, a leading expert in valve technology, "Duplex Ball Valves optimize flow control in challenging environments." This statement emphasizes their efficiency.

Many industries rely on Duplex Ball Valves for their ability to handle high-pressure conditions. These valves offer a unique advantage of corrosion resistance, particularly in harsh settings. Users often praise their long service life, but not all Duplex Ball Valves meet the highest standards. Some alternatives can fall short regarding reliability or maintenance needs.

When selecting the best Duplex Ball Valves, one must consider various factors. Features such as materials, pressure ratings, and manufacturer reputation matter. Understanding these elements can make a significant difference in application success. The options available today reflect advancements and innovations in valve design. However, discerning the best choice can require careful thought and assessment.

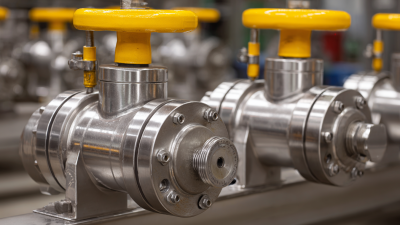

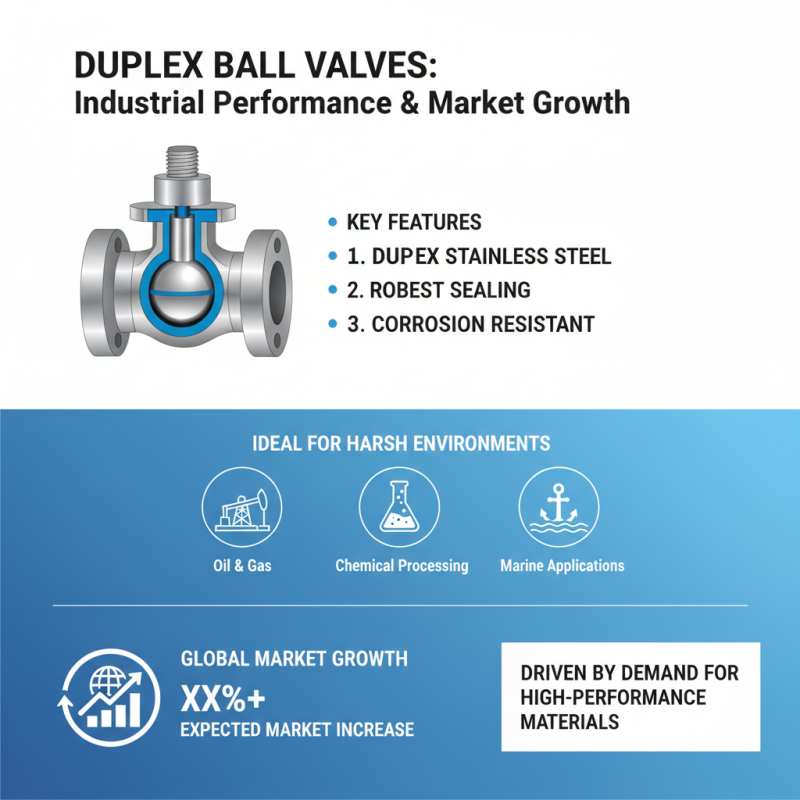

Duplex ball valves play a crucial role in various industrial applications. They feature a unique design, combining the strength of duplex stainless steel with effective sealing capabilities. This makes them suitable for harsh environments, including oil and gas, chemical processing, and marine applications. According to industry reports, the global duplex stainless steel valve market is expected to grow significantly, driven by increasing demand for high-performance materials.

These valves provide excellent corrosion resistance and durability. In environments where standard materials might fail, duplex valves maintain integrity and performance. They withstand high pressures and temperatures, crucial for safe operations. However, not all duplex valves are created equal. Regular maintenance is needed to ensure proper function and avoid possible leaks.

Tips: It’s essential to choose duplex valves that meet specific application requirements. Evaluate the chemical compatibility and temperature ranges. Checking for certifications can help in selecting high-quality products. Also, inspecting and testing valves regularly reduces the risk of operational failures. Capacity ratings should align with operational demands for maximum efficiency. Proper installation and regular updates on industry standards are necessary for optimal performance.

Duplex ball valves are essential in various industrial applications. They offer unique advantages due to their robust construction. These valves are made from duplex stainless steel, which provides high resistance to corrosion and pitting. This feature is crucial in industries dealing with harsh chemicals.

One notable benefit of duplex ball valves is their durability. They can withstand extreme temperatures and pressures. This ensures reliable operation in challenging environments. Additionally, their design allows for smooth operation. They can easily handle liquid and gas flow without leakages. However, users must regularly inspect them for wear and tear.

Another key feature is their low maintenance requirements. Users appreciate valves that minimize downtime. Duplex ball valves often fit this need, saving time and costs in repairs. Yet, improper installation can lead to issues. Attention to detail during setup is essential for optimal performance.

| Model | Material | Pressure Rating (PSI) | Temperature Range (°F) | Connection Type | Key Features | Benefits |

|---|---|---|---|---|---|---|

| DV-1000 | Duplex Stainless Steel | 1500 | -40 to 300 | Flanged | Corrosion-resistant, high strength | Extended lifespan, reduced maintenance |

| DV-2000 | Duplex Stainless Steel | 2000 | -20 to 250 | Welded | High toughness, low thermal expansion | Consistent performance under extreme conditions |

| DV-3000 | Duplex Stainless Steel | 2500 | -30 to 280 | Threaded | Design for superior flow control | Enhanced efficiency in fluid systems |

| DV-4000 | Duplex Stainless Steel | 3000 | -50 to 300 | Socket Weld | Self-draining design, easy to maintain | Optimal performance in critical applications |

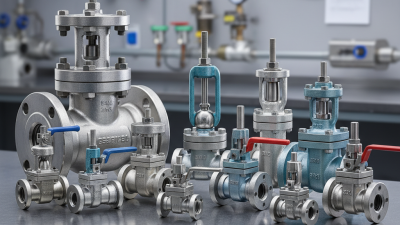

In 2026, selecting the right duplex ball valve for industrial applications is crucial. These valves are known for their durability and resistance to corrosion. They are often used in harsh environments, where standard valves may fail. A variety of manufacturers offer options for different needs and specifications.

When exploring top brands, consider materials and design features. Stainless steel and duplex stainless steel provide excellent longevity. Many manufacturers focus on the efficiency of flow control. However, not all designs meet the required industrial standards, which can lead to issues. It’s essential to review the technical details before making a final choice.

Quality assurance is another critical aspect. Some brands have robust testing protocols to ensure reliability. Yet, even respected manufacturers can have occasional lapses. Potential buyers should investigate user reviews and performance records thoroughly. In some cases, the most marketed valves may not deliver the best results.

When selecting duplex ball valves for industrial applications, understanding their material, design, and functionality is crucial.

Duplex stainless steel is often favored for its strength and corrosion resistance. This material performs well in harsh environments, making it a reliable choice.

However, not all duplex materials are created equal, and buyers must consider factors like cost-effectiveness and performance longevity.

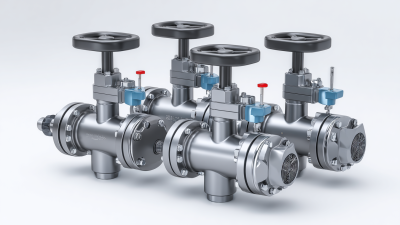

The design of duplex ball valves significantly impacts their functionality. Different designs offer unique flow characteristics. For example, some valves allow for a full port design, enabling maximum flow. This is important in high-demand systems. Meanwhile, other designs focus on space efficiency. It’s easy to overlook the impact of design until it's too late. Understanding these nuances can make a difference in operational efficiency.

On functionality, duplex ball valves excel in on/off applications. Their quick operation can reduce downtime. Yet, some users may find certain models do not perform under extreme conditions as promised. This discrepancy is vital to address during selection. Attention to detail in both design and expected performance can help prevent unforeseen complications.

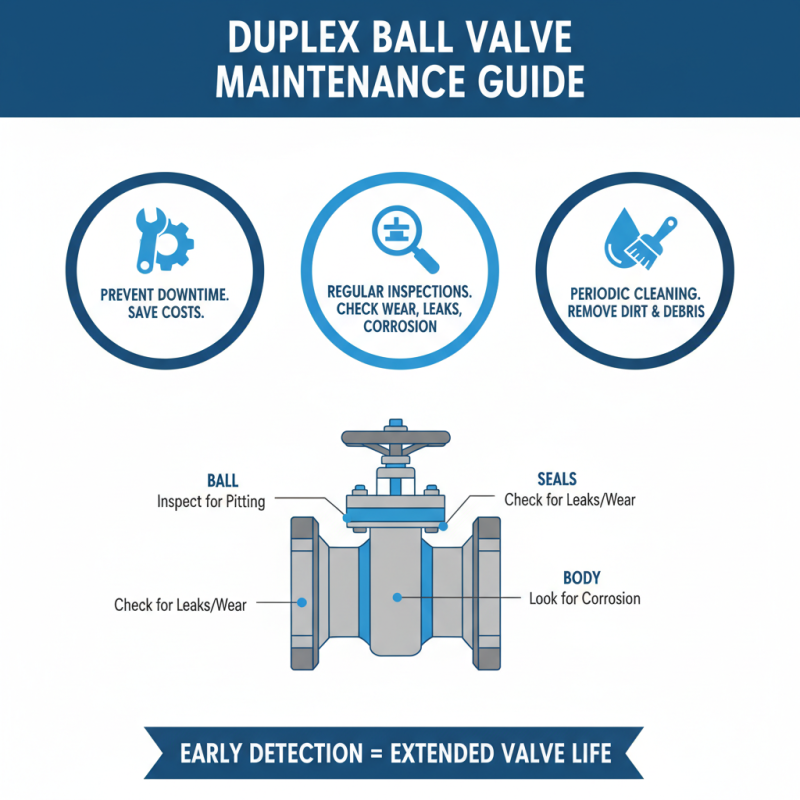

Duplex ball valves are essential in many industrial systems. Proper maintenance can prevent costly downtime. Regular inspections are key. Check for signs of wear, leaks, and corrosion. A visual inspection can catch issues early. It is also beneficial to clean the valves periodically. Dirt and debris can hinder performance.

Installation requires attention to detail. Ensure the valve aligns with the piping system. Misalignment may lead to failure. Use the right tools during the installation. Tighten bolts evenly to avoid stress points. Pay attention to the manufacturer’s specifications. Sometimes, guidelines can be overlooked, which leads to problems later.

Training staff on maintenance practices is vital. Knowledge gaps can cause mishaps. Everyone involved should understand the operational protocols. Document maintenance activities thoroughly. This not only helps with tracking but also serves as a future reference. Regular training sessions can mitigate risks. Small oversights can lead to major setbacks.