-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

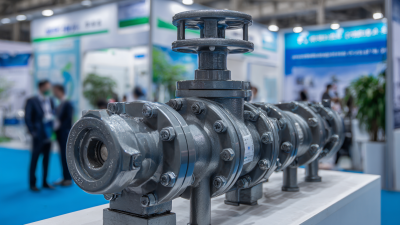

In the world of industrial flow control, the Screwed End Ball Valve stands out as a pivotal component that combines reliability with efficiency. This guide aims to delve into the intricacies of Screwed End Ball Valves, exploring their unique features, numerous benefits, and diverse applications across various industries. Understanding the fundamental aspects of these valves is essential for engineers, procurement specialists, and facility managers who seek to optimize their systems for performance and safety.

From their simple yet effective design to their capability of handling high-pressure environments, Screwed End Ball Valves provide unmatched versatility in applications ranging from water treatment to oil and gas pipelines. Join us as we unravel why these valves are the go-to choice for professionals seeking a durable and efficient solution for flow control needs.

Screwed end ball valves are essential components in various piping systems, offering unique design features tailored for efficiency and durability. One of the key design features is the threaded end connection, which allows for easy installation and disassembly, making maintenance more manageable. This design also provides a strong sealing capability, minimizing the risk of leaks and ensuring reliable operation in both low and high-pressure applications. The construction materials typically include brass, stainless steel, or carbon steel, chosen for their resistance to corrosion and wear, which enhances the valve's lifespan.

In terms of specifications, screwed end ball valves come in a variety of sizes, pressure ratings, and temperature ranges to suit diverse operational requirements. They are available in both two-way and three-way configurations, enabling versatile flow control options. The ball inside the valve is usually designed with a polished surface to reduce friction, ensuring smooth operation when opening or closing. Additionally, many models incorporate an innovative seat design that provides a bubble-tight seal, further expanding their use in critical applications across industries such as oil and gas, water treatment, and chemical processing.

Screwed end ball valves are increasingly recognized for their efficiency in various industrial applications. According to a report by Grand View Research, the global ball valve market is projected to reach over $9 billion by 2027, with a significant portion attributed to the popularity of screwed end designs. This trend is largely due to their superior sealing capabilities and ease of installation, which lead to reduced operational costs. Industries such as oil and gas, water treatment, and chemical processing rely heavily on these valves to ensure uninterrupted flow while minimizing energy losses.

Longevity is another critical advantage of screwed end ball valves. Studies show that these valves can last for over 20 years with proper maintenance, significantly outpacing traditional valve designs. The durable materials used in these valves, like stainless steel and brass, contribute to their resistance against corrosion and wear. Furthermore, a recent survey by the Valves and Actuators Market Forum indicated that 75% of maintenance professionals prefer screwed end ball valves due to their reliability and low maintenance requirements. As businesses increasingly prioritize cost-effectiveness, the long lifespan and reduced need for replacement make screwed end ball valves a smart investment in an era where budgets are often tight.

| Feature | Description | Benefit | Application |

|---|---|---|---|

| Durable Construction | Made from high-quality materials like brass and stainless steel. | Increased longevity and resistance to corrosion. | Oil and gas industry pipelines. |

| Easy Installation | Screwed end design allows for quick and simple installation. | Reduced labor costs and installation time. | Water supply systems. |

| Operational Efficiency | Provides precise flow control with minimal pressure drop. | Improves overall system efficiency. | Chemical processing plants. |

| Versatile Applications | Can be used in a variety of fluids, including gas, water, and oil. | Adaptability for different projects. | Heating systems, industrial and residential applications. |

| Cost-Effectiveness | Relatively low initial purchase cost and maintenance expense. | Lower total cost of ownership over time. | Small to medium-sized businesses and projects. |

Screwed end ball valves are increasingly vital components across various industries, particularly in oil, water systems, and many other applications. Their robust design and ease of installation make them ideal for managing flow in critical infrastructure. According to recent market insights, the global air compressor rental market is projected to reach USD 8,221.1 million by 2033, growing at a CAGR of 6.8%. This growth indicates an escalating demand for efficient control systems, where reliable ball valves play a crucial role.

Screwed end ball valves are increasingly vital components across various industries, particularly in oil, water systems, and many other applications. Their robust design and ease of installation make them ideal for managing flow in critical infrastructure. According to recent market insights, the global air compressor rental market is projected to reach USD 8,221.1 million by 2033, growing at a CAGR of 6.8%. This growth indicates an escalating demand for efficient control systems, where reliable ball valves play a crucial role.

Tips: When selecting screwed end ball valves for your operations, consider compatibility with your specific fluid types and pressure requirements to ensure optimal performance. Additionally, maintenance factors such as ease of accessibility for repairs can enhance overall system efficiency and longevity.

In the context of recent trends, the steam trap market is experiencing considerable shifts, with significant growth driven by advancements in product types, including mechanical and thermostatic traps. As industries evolve, the integration of sophisticated valve systems like screwed end ball valves will be essential in enhancing operational efficacy and sustainability. Investing in high-quality valves can lead to reduced downtime and operational costs, strengthening overall industry performance.

When it comes to the installation of screwed end ball valves, correct procedures are essential for ensuring optimal performance. Begin by examining the valve and the surrounding piping for compatibility; both should be rated for the same pressure and temperature conditions. During installation, use the appropriate pipe joint compound or Teflon tape on the threads to prevent leaks, ensuring that the tape does not enter the valve body. It is crucial to avoid over-tightening, which can damage the valve threads and the pipe, leading to potential failures.

Regular maintenance is equally important for keeping ball valves in top working condition. Schedule periodic inspections to check for leaks, corrosion, and signs of wear. Lubricating the valve stem can help in achieving smooth operation, while exercising the valve periodically prevents seizing. Additionally, if any unusual behavior is noticed—such as difficulty in operation or unusual sounds—servicing or replacing the valve should be prioritized to avoid system disruptions. Following these best practices will not only prolong the life of the ball valves but also enhance overall system reliability.

This bar chart illustrates the performance metrics of screwed end ball valves, showcasing the leakage rate, operating pressure, temperature range, installation time, and maintenance frequency. These metrics reflect the reliability and efficiency of these valves in various applications.

In fluid control systems, the choice of valve type is crucial for optimizing performance and efficiency.

Screwed end ball valves offer distinct advantages when compared to other valve types, such as gate or globe valves.

They are known for their straightforward design, which facilitates easy installation and maintenance.

The robust sealing capability of screwed end ball valves ensures a reliable shut-off, making them particularly effective in

high-pressure applications. Furthermore, their compact size and high flow capacity allow for seamless integration into a variety of systems, catering

to both industrial and residential needs.

Recent developments in valve technology, particularly concerning hydrogen applications, highlight the importance of selecting the appropriate valve type for emerging energy solutions. As the industry gears towards cleaner energy alternatives, the compatibility of materials and sealing mechanisms in various valves becomes critical. Comparative analysis reveals that while traditional valve types may suffice for many applications, the specialized requirements for hydrogen service underscore the need for innovation in valve design. Thus, while screwed end ball valves excel in many scenarios, ongoing advancements ensure that other valve types also remain relevant in an evolving marketplace.