-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the realm of industrial applications, the significance of choosing the right equipment cannot be overstated. Among the various components that facilitate efficient fluid control, the Tubing Ball Valve stands out as a crucial element for ensuring optimal performance. Designed to manage the flow of liquids and gases with precision, these valves utilize a spherical disc to halt or allow passage through a passageway, providing reliable sealing capabilities. With various designs and materials available, selecting the ideal Tubing Ball Valve can greatly impact operational efficiency and safety.

This article delves into the top 10 Tubing Ball Valves currently available on the market, examining their performance, durability, and suitability for different applications. Whether for oil and gas extraction, chemical processing, or water management, these valves are engineered for reliability and enhanced flow control. Understanding the features and benefits of each option will equip professionals with the knowledge needed to make informed decisions, ensuring optimal functionality in their specific operational environments. As we explore these top contenders, we will emphasize how they can elevate performance standards across diverse industries.

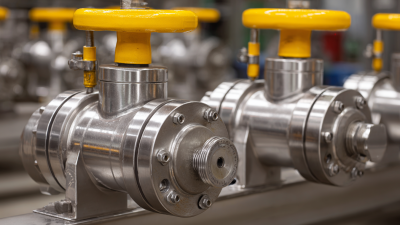

Tubing ball valves play a crucial role in various industrial applications, particularly in the oil and gas sector. These valves are designed to control the flow of fluids within a pipeline system, ensuring optimal performance under varying pressure and temperature conditions. The design of tubing ball valves, which typically includes a spherical disc that can rotate to open or close the flow path, allows for quick isolation and precise control. This is essential not only for maintaining system integrity but also for preventing leakages that could lead to hazardous situations.

The importance of tubing ball valves extends beyond simple flow regulation; they contribute significantly to safety and efficiency in operations. In high-pressure environments, these valves must be reliable and durable, capable of withstanding extreme conditions while providing minimal resistance to flow. Proper selection and maintenance of tubing ball valves can lead to enhanced system performance, reduced downtime, and lower operational costs. Moreover, their ease of operation ensures that personnel can swiftly execute necessary actions in critical situations, further underscoring their value in performance optimization within industrial settings.

This chart illustrates the performance ratings of the top 10 tubing ball valves, showcasing their efficiency and effectiveness in various applications. Performance ratings are critical for selecting the appropriate valve for optimal operational success.

When selecting tubing ball valves, several key features are essential for ensuring optimal performance in various industrial applications. One of the primary considerations is the valve's material composition, which significantly affects durability and resistance to corrosion. According to a 2022 market report from the International Society of Automation, stainless steel and brass are among the most commonly recommended materials due to their robustness and ability to withstand extreme temperatures and pressures, making them ideal for oil and gas applications.

Another crucial factor to consider is the valve's size and end connections. Proper sizing ensures that the valve can handle the required flow rates without compromising system efficiency. A study by the American Society of Mechanical Engineers highlights that proper valve sizing can lead to a 20% increase in energy efficiency within fluid systems. Additionally, matching the end connections with the piping system is vital to prevent leaks and facilitate easy installation and maintenance, thereby reducing downtime in production.

Finally, the valve's pressure rating is a critical specification. Many applications operate under high pressure, and a valve's pressure rating determines its reliability and safety in such environments. Research indicates that tubing ball valves with higher pressure ratings not only enhance safety but also extend the lifespan of the valve, contributing to overall system reliability. Selecting valves that meet or exceed industry standards for pressure ratings is, therefore, imperative for optimal performance in demanding applications.

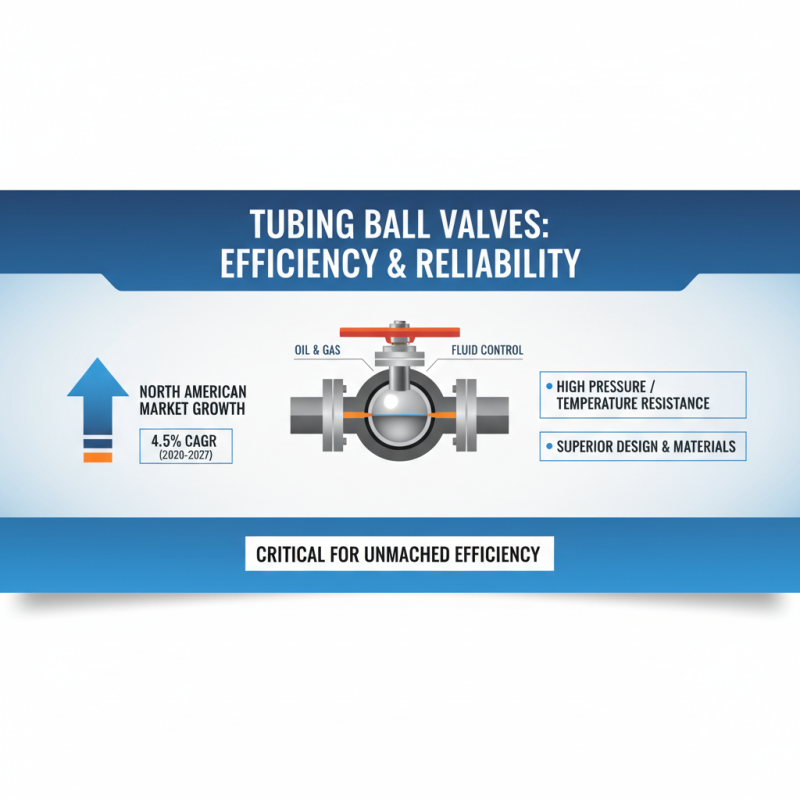

Tubing ball valves are critical components in various industries, particularly oil and gas, where efficiency and reliability are paramount. The demand for high-performance ball valves has grown significantly, with market reports indicating an expected compound annual growth rate (CAGR) of 4.5% from 2020 to 2027 in the North American market alone. This growth is driven by the increasing need for reliable fluid control systems that can withstand high pressures and extreme temperatures, making superior design and material choice essential in achieving unmatched efficiency.

Recent studies highlight that the right selection of tubing ball valves can lead to significant benefits, including reduced operational costs and enhanced system reliability. For instance, valves made from high-grade materials such as stainless steel or carbon steel exhibit superior resistance to corrosion and wear, leading to lower maintenance costs and longer service life. Furthermore, advancements in valve design, such as the implementation of blowout-proof stem designs and pressure balancing features, enhance both the performance and safety of these valves in demanding applications, ensuring they meet safety standards and exceed operational expectations.

In applications ranging from chemical processing to water treatment, the efficiency of tubing ball valves directly impacts the overall productivity of the operations. By optimizing the flow paths and minimizing turbulence, these valves can improve flow rates by as much as 15% compared to traditional valve designs. Such enhancements in performance underscore the importance of selecting the right tubing ball valves to achieve operational excellence, highlighting their role as indispensable tools in contemporary fluid control systems.

When selecting tubing ball valves, performance metrics such as flow rate, pressure rating, and durability become critical. According to a recent industry report by the Global Valve Market Analysis, the use of high-performance tubing ball valves can increase system efficiency by up to 20% in oil and gas applications. These valves are designed to offer minimal pressure drop and efficient flow control, making them ideal for high-demand environments. The report highlights that the right materials used in manufacturing, such as carbon steel and stainless steel, significantly enhance the lifespan and reliability of these valves in harsh conditions.

A comparative analysis of tubing ball valves also reveals nuances in operational features that can affect end-user decisions. Features like full-bore design enable unrestricted flow, minimizing turbulence and wear over time. Furthermore, recent surveys among industry professionals indicate a preference for valves that comply with American Petroleum Institute (API) standards, ensuring safety and efficiency. The prevalence of automated control systems integrated with modern ball valves is also noteworthy, as it allows for precise monitoring and adjustments, resulting in reduced operational costs and improved performance metrics. These insights underline the importance of rigorous performance evaluation when choosing the best tubing ball valves available in the market.

Maintaining tubing ball valves is essential for ensuring their optimal performance and longevity. Regular inspection is a key aspect of maintenance. Operators should routinely check for leaks, corrosion, and any signs of wear on the seals and seats of the valve. Addressing minor issues early can prevent more significant failures and costly downtime in the long run. It's also advisable to keep a maintenance log, documenting any repairs or findings during inspections to track the valve's condition over time.

Lubrication is another critical factor for the performance of tubing ball valves. Appropriate lubrication helps in reducing friction and preventing mechanical wear. It's important to use the right type of lubricant, as specified in the valve's operational guidelines, to ensure compatibility with the materials used in the valve construction. Additionally, operators should be cautious about the environment in which the valves are operating, as extreme temperatures or exposure to harsh chemicals can affect both the lubrication and the valve materials. Regularly scheduled maintenance and prompt attention to lubrication needs will significantly enhance the reliability and efficiency of tubing ball valves.