-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

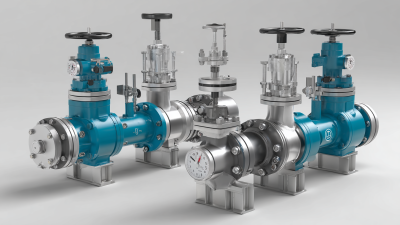

Ball valves are critical components in various industries. They control the flow of liquids and gases with precision and ease. Understanding their types and features is essential for engineers and project managers.

In this article, we will explore the top 10 ball valves you should know about. These valves have unique designs and materials, tailored for specific applications. Some are built for high pressure, while others excel in corrosive environments.

Choosing the right ball valve can be challenging. There are many options, and each has its pros and cons. We will highlight the key aspects you need to consider. With this knowledge, making informed decisions will be more manageable.

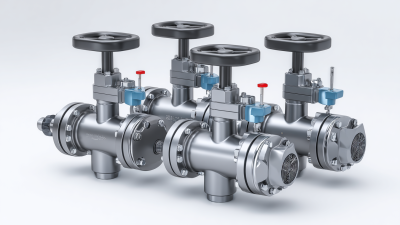

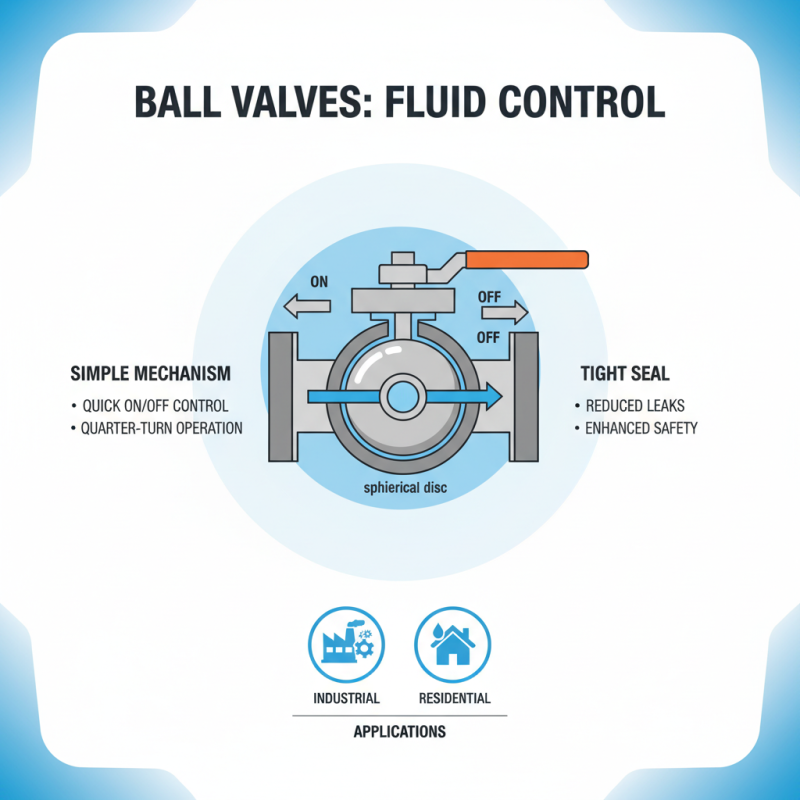

Ball valves are essential in many industries. They control the flow of liquids and gases. Their design features a spherical disc that rotates. This mechanism makes them efficient for on/off applications. Typically, they are used in water supply, gas distribution, and chemical processing.

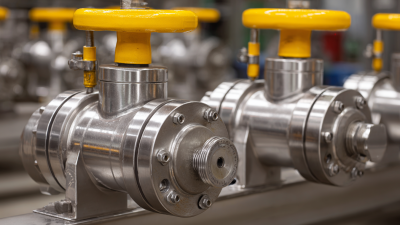

Understanding how to choose the right ball valve is crucial. Consider the material that fits your system. Common materials include brass, stainless steel, and plastic. Each material has unique properties suited for specific environments. Pay attention to pressure ratings and temperatures too.

**Tip:** Always check the valve's compatibility with the fluids involved.

Installation requires precision. A poorly installed valve can lead to leaks. Take time to ensure proper alignment and sealing. Regular maintenance is necessary for optimal performance. Neglect can cause failures, leading to costly repairs.

**Tip:** Create a maintenance schedule to avoid issues.

Ball valves are versatile but not foolproof. They can stick if not used regularly. Inspect them periodically. Operators must be trained to manage any potential complications. Understanding the application is key to success.

Ball valves are essential components in fluid control systems. They offer a simple mechanism for regulating flow. With a spherical disc, they allow for quick on/off control. This functionality is vital in both industrial and residential applications. Their ability to create a tight seal is unmatched. This reduces the risk of leaks significantly, ensuring safety.

One of the key features of ball valves is their durability. Made from robust materials, they withstand high pressures and temperatures. This makes them reliable over extended periods. Additionally, ball valves require minimal maintenance. This is a major advantage in busy environments. They can operate smoothly even after years of use.

However, ball valves are not without challenges. They may struggle with throttling applications due to their design. This can lead to inefficient flow control in some scenarios. Users should consider this limitation when selecting a valve. Understanding the specific needs of your system is crucial for optimal performance.

When selecting ball valves, performance and reliability are key. A sturdy valve can withstand high pressures and extreme temperatures. Look for materials that resist corrosion. Stainless steel is a good choice for many applications. Always consider the environment where the valve will be installed.

Tips: Regular maintenance can enhance the lifespan of your ball valve. Check seals and fittings for signs of wear. A small leak can lead to significant problems over time. Always keep spare parts handy to avoid unexpected downtime.

Not all ball valves perform the same. Some may fail under stress, while others offer robust solutions. Testing valves under real conditions can provide better insights. Remember that the best valve for one application may not work for another. Consider the specific requirements of your project carefully.

When choosing ball valves, material and design significantly impact performance.

Common materials include stainless steel, brass, and PVC. According to a recent industry report, stainless steel valves offer superior corrosion resistance. They are often recommended for harsh environments. However, they can be more expensive than other options.

Ball valves are crucial in various applications. To ensure their longevity, regular maintenance is essential. Start by inspecting the valve regularly for any signs of wear or damage. Look for leaks around seals and joints. Even small leaks can lead to more significant issues over time. Inspect the ball and seats for corrosion, which can affect performance.

Lubrication is another key aspect. Use appropriate lubricants to keep the valve operating smoothly. Avoid over-lubricating, as excess can attract dirt. Additionally, cycling the valve periodically helps keep it functioning properly. Neglecting to do this can lead to stiffness or seizing. If the valve is not in use, consider a protective cover to shield it from debris.

Cleaning the valve is simple yet often overlooked. A damp cloth can help remove dirt and grime. For stubborn build-up, use appropriate cleaning agents. Ensure that no residue remains, as it can interfere with the valve's operation. Regular maintenance may seem tedious, but it pays off. Ignoring these steps could result in costly replacements or repairs. Make maintenance a habit for the longevity of your ball valves.

| Valve Type | Material | Size Range | Pressure Rating | Maintenance Tips |

|---|---|---|---|---|

| Floating Ball Valve | Stainless Steel | 1/2" to 12" | 150 to 600 PSI | Regularly inspect seals and lubricate threads. |

| Trunnion Mounted Ball Valve | Carbon Steel | 2" to 24" | 150 to 1500 PSI | Check for wear on ball and seals, replace as necessary. |

| Reduced Bore Ball Valve | PVC | 1" to 3" | 100 to 200 PSI | Clean regularly to avoid build-up and jamming. |

| Full Bore Ball Valve | Brass | 1/2" to 6" | 150 to 300 PSI | Routine greasing of the valve stem to ensure smooth operation. |

| Electric Ball Valve | Stainless Steel & Plastic | 1" to 10" | 150 to 600 PSI | Check electrical connections and clean actuator regularly. |

| Pneumatic Ball Valve | Aluminum | 1" to 8" | 150 to 450 PSI | Inspect pneumatic seals for wear, replace if necessary. |

| Lever Operated Ball Valve | Bronze | 1/4" to 4" | 100 to 400 PSI | Ensure lever is not obstructed; perform visual checks regularly. |

| Socket Weld Ball Valve | Stainless Steel | 1" to 4" | 150 to 600 PSI | Inspect welds for integrity and check for leaks periodically. |

| Threaded Ball Valve | PVC | 1/2" to 6" | 50 to 150 PSI | Tighten threaded connections but avoid over-torquing. |