-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

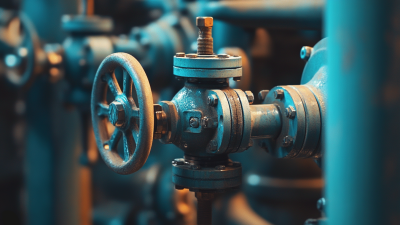

In the realm of industrial applications, the efficiency of fluid control systems is pivotal, particularly when dealing with extreme conditions. High Temperature Ball Valves have emerged as critical components in ensuring operational reliability under elevated temperatures, often exceeding 500°F (260°C). According to a report by Research and Markets, the global ball valve market is expected to grow significantly, with high temperature variants driving innovation and investment in safety and performance enhancements. These valves are not only designed to withstand harsh environments but also to optimize flow rates and minimize leakage, reducing operational costs.

As industries strive to meet stringent regulatory standards and enhance efficiency, understanding and implementing optimal strategies for High Temperature Ball Valve performance becomes imperative, paving the way for enhanced productivity and sustainability in various sectors including oil and gas, chemical processing, and power generation.

High temperature ball valves are essential components in many industrial applications, particularly in chemical processing, power generation, and petrochemical sectors. These valves are designed to withstand temperatures exceeding 300°C (572°F) while maintaining high performance and reliability. However, the unique challenges presented by high-temperature environments can lead to issues such as thermal expansion, seal degradation, and material limitations. According to a recent report by the International Society of Automation, nearly 30% of valve failures in severe conditions are attributed to inadequate thermal management.

To optimize the performance of high temperature ball valves, manufacturers and operators should focus on specific strategies. First, selecting the appropriate materials is crucial; utilizing high-quality alloys and composites with better thermal resistance can significantly extend service life. Additionally, careful attention must be paid to actuator selection, ensuring they can function effectively within the expected temperature range.

Tip: Regular maintenance checks should include thorough inspections of valve seals and actuators, particularly for wear and tear, to prevent unexpected failures. Furthermore, installing thermal insulation around the valve helps to regulate temperature fluctuations, minimizing the stress on valve components.

Adhering to these strategies not only improves the performance of high temperature ball valves but also enhances overall system reliability, ensuring that industrial operations run smoothly and efficiently.

High temperature ball valves play a crucial role in industrial applications, where their performance can significantly influence operational efficiency and safety. One of the key factors affecting their performance is the material composition. Selecting materials that can withstand extreme temperatures while maintaining structural integrity is essential to prevent leaks and ensure reliability. For instance, advanced alloys and composite materials are commonly used to enhance the durability and longevity of these valves in high-stress environments.

Another critical factor is the valve design itself. Multi-segmental baffle designs have been shown to optimize flow characteristics and pressure distribution within the valve, leading to improved performance. This design not only minimizes turbulence and cavitation but also helps in maintaining consistent operating conditions, which is vital for processes requiring precise fluid control. Additionally, regular maintenance and monitoring of valve performance are necessary to address wear and tear, ensuring that the valves function optimally throughout their operational lifespan.

| Strategy | Description | Key Factors | Impact on Performance |

|---|---|---|---|

| Material Selection | Choosing materials that can withstand high temperatures and corrosive environments. | Temperature tolerance, corrosion resistance. | Enhanced durability and lifespan of valves. |

| Regular Maintenance | Implementing a routine maintenance schedule to inspect and service valves. | Inspection frequency, maintenance techniques. | Prevention of failures and reduction of downtime. |

| Proper Installation | Ensuring that valves are installed correctly to avoid stress and leaks. | Installation techniques, alignment accuracy. | Improved sealing and reduced risk of leaks. |

| Performance Testing | Conducting tests to assess valve function under high temperature conditions. | Testing procedures, temperature limits. | Verification of valve reliability and performance standards. |

| Use of Actuators | Incorporating high-performance actuators that can withstand elevated temperatures. | Actuator material, operating limits. | Enhanced control and operational efficiency. |

When it comes to high temperature ball valve applications in industrial settings, selecting the right materials is crucial for optimizing performance and longevity. According to a 2021 report by Research and Markets, the global industrial valve market is projected to reach $85.21 billion by 2026, with a significant portion accounted for by high-temperature valves. This necessitates an understanding of which materials can withstand demanding thermal conditions without compromising structural integrity.

Materials such as stainless steel, particularly grades 316 and 347, are frequently recommended due to their excellent resistance to heat and corrosion, making them suitable for high-temperature environments reaching up to 800°F (427°C). Additionally, high-performance alloys like Inconel and Hastelloy offer superior durability and resistance to oxidation, often used in petrochemical and power generation industries. According to a study published by the American Society of Mechanical Engineers, these alloys can maintain mechanical properties at temperatures exceeding 1000°F (538°C), ensuring they perform effectively in extreme conditions. Choosing the right material not only enhances valve performance but also contributes to reducing maintenance costs and downtime in industrial applications.

Maintaining high temperature ball valves in industrial applications is crucial for ensuring their longevity and reliable performance. According to a report by the International Journal of Pressure Vessels and Piping, improper maintenance can lead to significant operational failures, costing industries up to 30% of their annual maintenance budget. To prevent such losses, implementing a robust maintenance strategy that includes regular inspections and predictive maintenance practices is essential. This proactive approach helps identify wear and fatigue before they escalate into catastrophic failures.

One effective method for enhancing ball valve longevity is the implementation of thermal cycling management, which helps to mitigate thermal shock and associated stresses. A study published by the American Society of Mechanical Engineers found that valves subjected to frequent thermal cycles experienced a 40% increase in wear rates compared to those under stable conditions. Incorporating advanced materials that are resistant to high temperature and corrosion can also contribute significantly to extending valve life. By utilizing these strategies, industries can improve their ball valve reliability and significantly reduce downtime and maintenance costs.

Innovative technologies for improving high temperature ball valve efficiency have emerged as a cornerstone of modern industrial innovation, offering unparalleled capabilities to enhance performance and sustainability. The introduction of sustainable zero leak magnetic valve technology marks a significant advancement in reducing harmful emissions, aligning with global environmental goals. This breakthrough can help industries significantly lower their carbon footprints while maintaining operational efficiency, a pressing need in today's eco-conscious market.

According to market projections, the global stainless steel control valve market is expected to expand from USD 1.13 billion in 2025 to USD 1.94 billion by 2035, reflecting a steady CAGR. This growth is fueled by the increasing demand for durable and efficient valve solutions across various sectors. Companies are also turning towards enhanced sealing solutions to tackle challenges in high-stress environments, showcasing the need for robust and reliable components.

**Tips for Optimizing High Temperature Ball Valve Performance:**

1. Invest in advanced seal materials that can withstand extreme temperatures to prevent leaks and failures.

2. Regularly monitor valve performance using predictive maintenance technologies to identify potential issues before they become critical.

3. Stay updated on industry innovations and adopt new technologies that promise improved efficiency and sustainability.