-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In today's fast-paced industrial environment, the demand for optimizing system performance is paramount, and floating ball valves have emerged as a vital component in achieving this goal. According to a report by Research and Markets, the global valve market is expected to reach $80 billion by 2025, with a significant portion attributed to the efficiency and reliability of floating ball valves in fluid control systems.

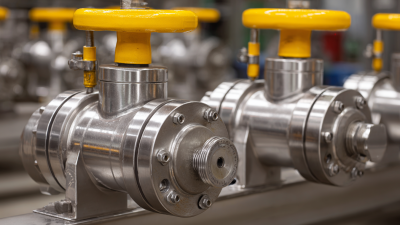

These valves, renowned for their simplicity and robust design, offer minimal pressure drop and enhanced sealing capabilities, crucial for various applications across industries such as oil and gas, water treatment, and chemical processing. As companies strive to minimize operational costs and maximize throughput, understanding and implementing effective strategies for using floating ball valves can lead to remarkable gains in efficiency and performance.

This blog will explore top strategies that can help industries harness the full potential of floating ball valves.

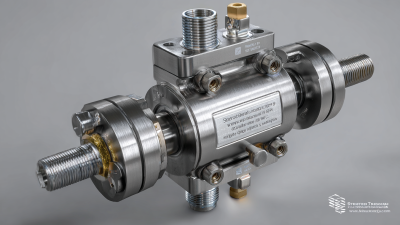

When discussing floating ball valves, several key factors influence their performance and efficiency. One of the primary aspects is the seat design, which directly affects the sealing capability and flow performance of the valve. A well-engineered seat ensures that the ball maintains a proper seal, preventing leakage and allowing for better control of fluid flow. Additionally, the choice of materials used for both the ball and the seat plays a crucial role in durability and resistance to wear, particularly in high-pressure applications or abrasive environments.

Another significant factor is the valve's size and compatibility with the system. An appropriately sized floating ball valve reduces turbulence and pressure drops, enhancing overall efficiency. Proper installation is also essential; misalignment can lead to premature wear and inadequate sealing. Regular maintenance checks are necessary to address any wear on the seats or the ball, ensuring that the valve operates optimally throughout its lifecycle. Overall, attention to these factors can result in improved efficiency and extended service life for floating ball valves in various industrial applications.

Maintaining the longevity of floating ball valves is crucial for maximizing efficiency in industrial applications. According to a study by the Valve Manufacturers Association, proper maintenance can enhance the lifespan of these valves by up to 30%. One innovative practice is the application of advanced sealing technologies, which can significantly reduce wear and tear caused by operational stress. Utilization of materials such as PTFE for seals not only improves resistance to various fluids but also minimizes the risk of leakage, ensuring a reliable performance over time.

Additionally, implementing a regular inspection schedule can preemptively identify issues that might lead to costly downtime. The American Society of Mechanical Engineers suggests that scheduled maintenance routines, including ultrasonic thickness measurements and vibration analysis, can detect inefficiencies long before they result in valve failure. By adopting these practices, industries can not only prolong the lifespan of their floating ball valves but also achieve notable cost savings, potentially decreasing maintenance expenditures by 20% according to recent industry reports. These strategic approaches underscore the importance of innovative maintenance in the effective management of floating ball valve performance.

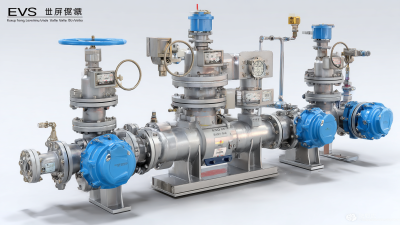

When evaluating the efficiency of floating ball valves, it’s crucial to compare them with other valve types, such as gate valves and globe valves. Floating ball valves operate by allowing the ball to float freely, which provides a tight seal against the seat, making them ideal for on/off service in various applications. This design results in lower operating torque, which contributes to less energy consumption. In contrast, gate valves often deal with higher pressure drops, leading to increased energy wastage during operation, especially in fluid control systems.

Moreover, the quick opening and closing functionality of floating ball valves enhances overall system responsiveness compared to globe valves, which require multiple turns to fully operate. This speed can significantly affect processes that rely on precise flow regulation and rapid shutoff, particularly in industries like oil and gas, water treatment, and chemical processing. By utilizing floating ball valves, organizations can achieve better operational efficiency, thereby reducing downtime and maintenance costs, which are common challenges associated with other valve types.

When selecting the right floating ball valve for your application, the first consideration should be the fluid characteristics you are dealing with.

Different fluids, whether they are corrosive, viscous, or contain solids, will dictate the type of materials the valve should be made from. For example, a stainless-steel valve might be ideal for corrosive environments, while a PVC valve could suffice for less aggressive fluids. Always ensure that the valve’s material is compatible with the medium to prevent premature failure and maintain system integrity.

Another critical factor is the pressure and temperature ratings of the valve. Each application has specific operational conditions, and it is essential to choose a floating ball valve that not only meets but exceeds these requirements to ensure reliability. Additionally, consider the size of the valve in relation to the piping system to avoid flow restrictions that could lead to inefficiencies.

Remember that a well-chosen floating ball valve can significantly enhance performance by providing tight sealing, ensuring minimal leakage, and optimizing flow control throughout your system.

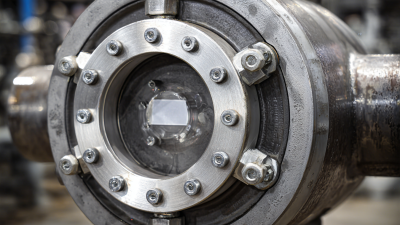

Floating ball valves are essential components in many industrial systems, but they can encounter common issues that hinder their efficiency. One frequent problem is leakage, which can arise from inadequate sealing due to wear or improper installation. To troubleshoot this, it's crucial to inspect the valve seating and the sealing materials regularly. Replacing worn-out seals and ensuring that the valve is correctly aligned can prevent costly downtime and maintain the integrity of the system.

Floating ball valves are essential components in many industrial systems, but they can encounter common issues that hinder their efficiency. One frequent problem is leakage, which can arise from inadequate sealing due to wear or improper installation. To troubleshoot this, it's crucial to inspect the valve seating and the sealing materials regularly. Replacing worn-out seals and ensuring that the valve is correctly aligned can prevent costly downtime and maintain the integrity of the system.

Another challenge in floating ball valve operations is sluggish or unresponsive movement. This issue often stems from the accumulation of debris in the valve body or actuator. Regular maintenance, including cleaning of the valve and checking for obstructions, can keep the ball free to move and respond promptly to control signals. Additionally, evaluating the actuator for proper functionality is essential, as a malfunctioning actuator can lead to ineffective operation. By addressing these common issues proactively, operators can significantly enhance the efficiency and reliability of floating ball valves in their systems.