-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

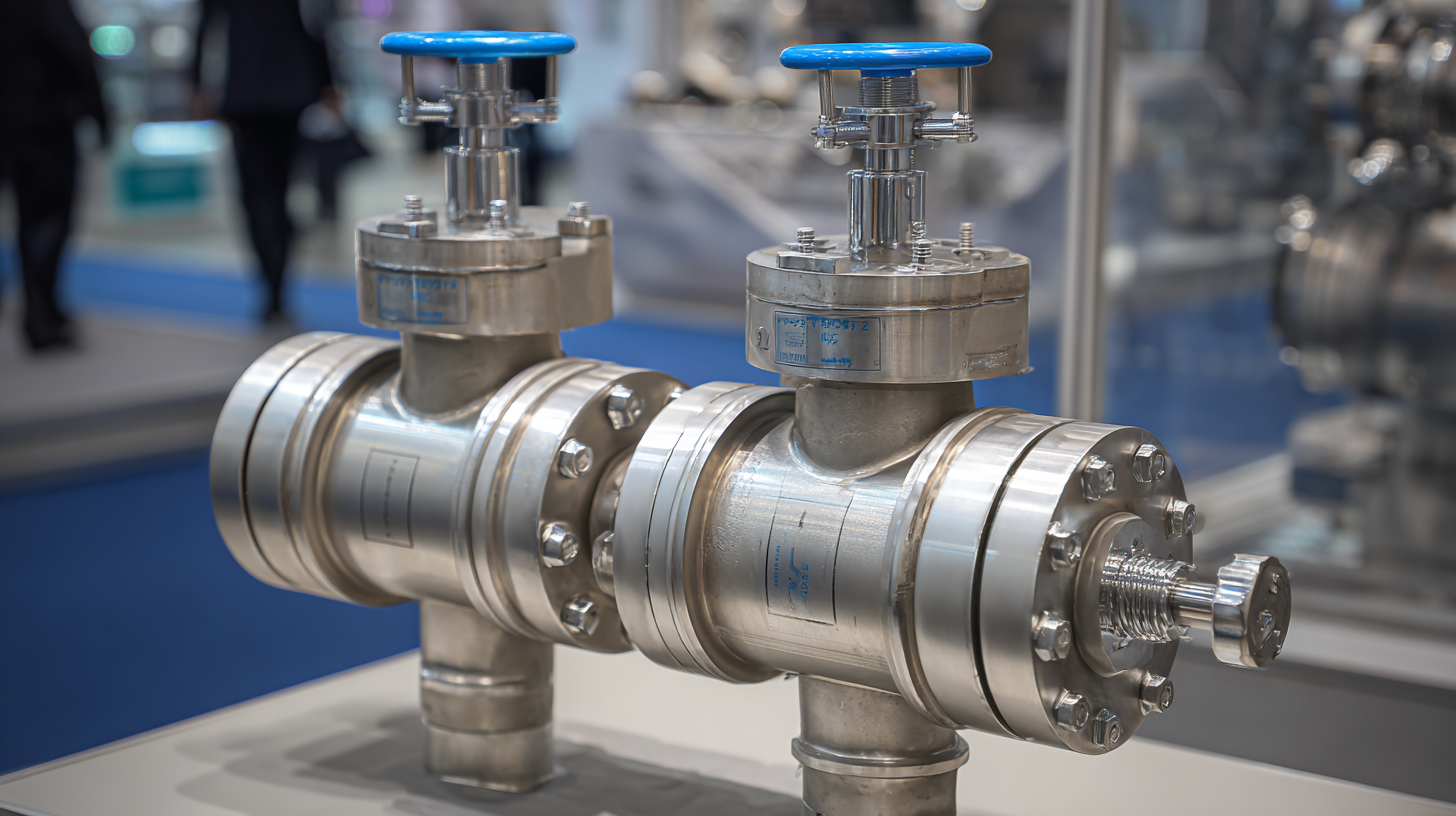

The upcoming 138th China Import and Export Fair in 2025 is set to be a pivotal event for industries across the globe, particularly in the realm of industrial valves, where the Double Ball Valve stands out as a significant focus. As markets become increasingly competitive and technology evolves, understanding the current market trends for Double Ball Valves is essential for manufacturers and distributors alike. This introduction explores the critical factors influencing the market dynamics, including innovations in valve design, shifts in consumer demand, and the impact of environmental regulations. Furthermore, the fair provides an invaluable platform for industry professionals to network, exchange ideas, and showcase advancements in Double Ball Valve technology. Attendees will gain insights into emerging trends and opportunities that could shape the future landscape of the valve manufacturing sector, making it an unmissable occasion for anyone involved in this critical industry.

As we approach the 138th China Import and Export Fair in 2025, the market for double ball valves is gaining significant attention. This key industry insight reveals that the demand for double ball valves is expected to rise due to their efficiency and reliability in various applications, particularly within the rapidly evolving energy sector. The integration of advanced technology and materials has cemented double ball valves as an essential component in modern industrial systems, making it critical for stakeholders to stay informed about emerging trends and innovations in this space.

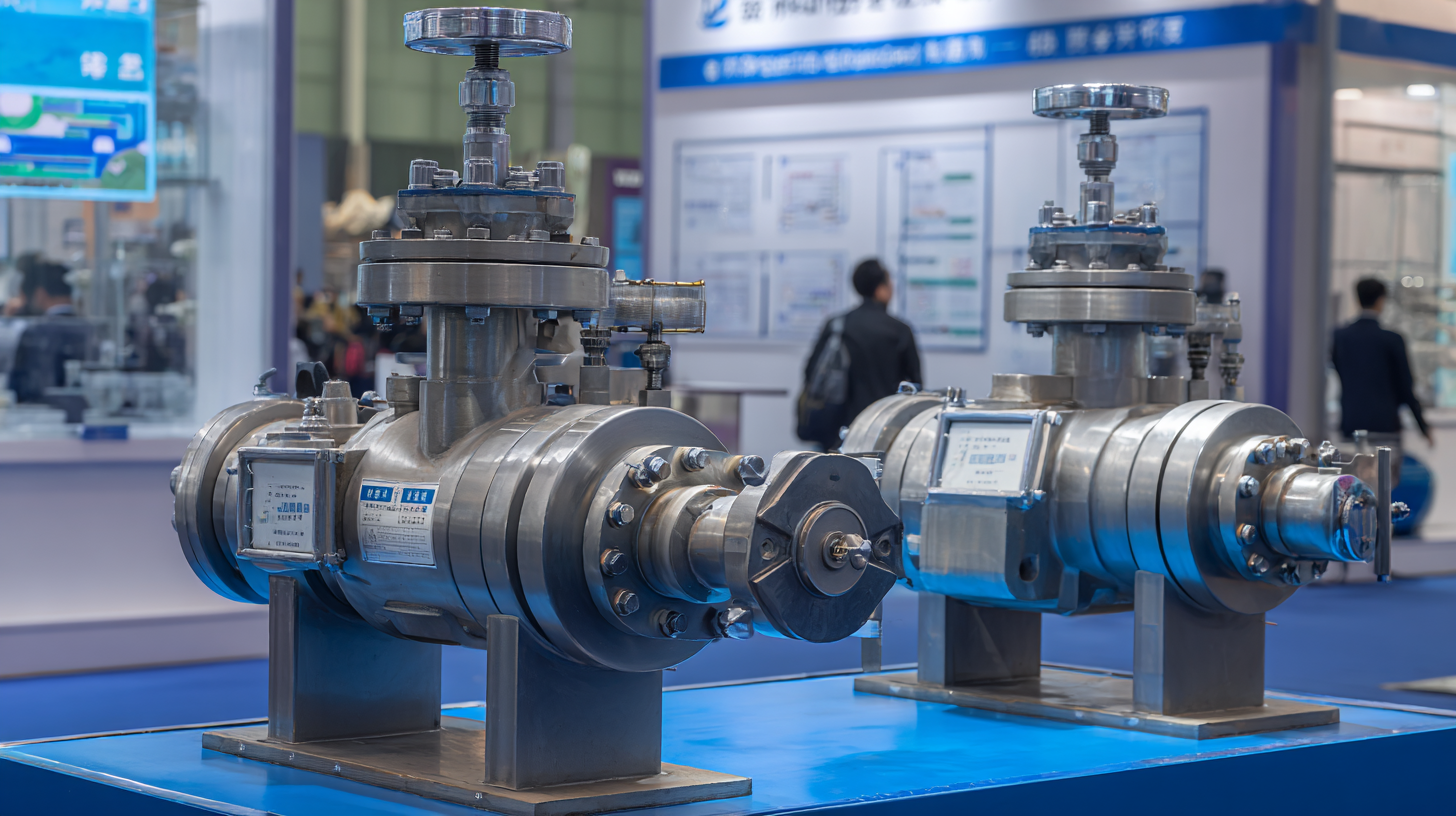

Jiangsu Huaying Valve Co., Ltd. will showcase its latest offerings at the CLNB 2025 New Energy Entire Industry Chain Expo, indicating a strong commitment to meeting the anticipated market growth. Set to be held from April 16 to 18, 2025, at the Suzhou International Expo Center, this event will gather key players in the new energy sector, providing an opportunity to discuss strategic developments and potential collaborations. The insights gained from such gatherings are vital as the global forged steel split body ball valve market is projected to experience dynamic growth from 2025 to 2031, emphasizing the importance of adaptation and innovation within the industry.

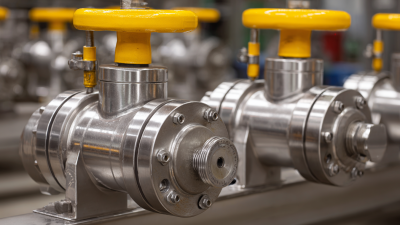

The double ball valves market is poised for significant growth from 2021 to 2025, reflecting broader trends within the industrial valve sector. As industries worldwide focus on efficiency and reliability, the demand for double ball valves continues to rise. This trend is driven by a shift towards automation and increased investments in infrastructure, which underscore the importance of precision in fluid control systems.

Forecasts indicate that the global industrial valve market, critical to the growth of double ball valves, is set to reach approximately $121.67 billion by 2024, with a compound annual growth rate (CAGR) of about 6.6% from 2025 to 2034. As manufacturers enhance their product offerings and technology, the double ball valves segment will likely capture a more substantial share of this expanding market. The focus on sustainability and advanced manufacturing techniques will further fuel growth, positioning double ball valves as essential components across various sectors.

As the 138th China Import and Export Fair approaches in 2025, the focus on double ball valve technology innovations is set to redefine market trends significantly. Recent reports by MarketsandMarkets projected that the global double ball valve market will reach approximately $1.43 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.3% from 2021. This surge can be attributed to the increasing demand for robust and efficient flow control solutions across various industries, including oil and gas, water treatment, and power generation.

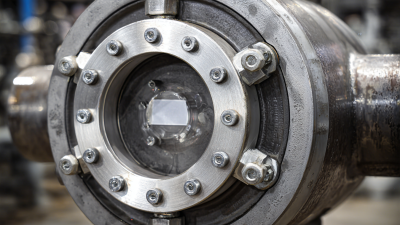

Innovative advancements in double ball valve technology are at the forefront of this market shift. Key developments include the introduction of smart valves equipped with Internet of Things (IoT) capabilities, allowing for real-time monitoring and enhanced operational efficiency. A study by Research and Markets highlights that the integration of automation and digitalization in valve technology could reduce maintenance costs by up to 30%, thereby driving further adoption. These innovations not only improve performance but also align with the industry’s push toward sustainability, meeting the growing regulatory pressures for energy-efficient solutions. As exhibitors present these pioneering technologies at the fair, attendees can expect insights into how these trends will shape the future of industrial applications globally.

The demand for double ball valves is experiencing notable growth, particularly in key regions of China. According to the latest report from MarketsandMarkets, the global valve market is projected to reach USD 96.36 billion by 2025, with a significant contribution coming from the Asia-Pacific region. In China, the rapid expansion of the oil and gas industry, combined with increasing investments in infrastructure projects, is propelling the demand for high-performance valves, including double ball valves.

In specific regions such as Guangdong and Jiangsu, the surge in manufacturing activities and industrial applications has led to heightened requirements for reliable and efficient flow control solutions. A study by ResearchAndMarkets highlights that the consumption of double ball valves in these provinces is expected to grow at a CAGR of 6.5% from 2023 to 2025, driven by the need for durable products that can withstand high pressure and temperature variations. As China continues to enhance its manufacturing capabilities and adheres to stricter industry standards, the role of double ball valves as critical components in various applications, ranging from petrochemical to water supply systems, will become increasingly significant.

This chart illustrates the projected demand for double ball valves across key regions in China for 2025, highlighting how different sectors contribute to market growth.

The competitive landscape for double ball valves in 2025 is characterized by a diverse array of key players, each implementing unique market strategies to carve out their niches. Leading manufacturers are focusing on innovation, investing heavily in research and development to enhance product performance and reliability. This commitment to technological advancement is crucial in meeting the evolving demands of industries such as oil and gas, water treatment, and chemical processing.

In addition to innovation, strategic partnerships and collaborations are becoming increasingly vital. Major players are forming alliances with local distributors and service providers to expand their market reach and improve customer service. These collaborations not only enable companies to gain insights into regional market dynamics but also help in reducing logistical challenges. Furthermore, sustainability initiatives are gaining traction, with manufacturers adopting eco-friendly practices and materials as part of their branding strategies, appealing to a growing segment of environmentally conscious consumers.