-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

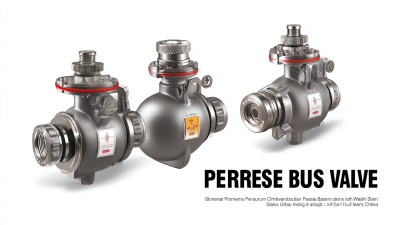

In recent years, the demand for efficient and reliable valve solutions has surged, driven by rapid advancements in industrial processes and stricter safety regulations. Among these, the Split Body Ball Valve has emerged as a critical component, offering advantages such as easy maintenance and reduced downtime. According to a report by Market Research Future, the global valve market is expected to reach USD 90 billion by 2025, largely fueled by the growing oil and gas sector and infrastructure development. Innovative approaches to Split Body Ball Valve solutions not only enhance operational efficiency but also adhere to environmental compliance, making them indispensable in various applications. As industries continue to evolve, it becomes essential to explore these innovative strategies that meet both performance expectations and sustainability goals.

The traditional split body ball valve design has been widely used in various industrial applications for its reliability and ease of maintenance. However, these conventional designs face significant challenges that can hinder performance and efficiency. One primary issue is the inherent complexity in the assembly process, which can lead to increased labor costs and longer installation times. Moreover, leaks can develop around the split joints if not properly sealed, resulting in costly downtime and maintenance.

Another challenge lies in the materials used for traditional split body construction. Many standard materials may not withstand harsh operating conditions, such as extreme temperatures and corrosive environments. This can lead to valve failure and necessitate frequent replacements, further compounding operational expenses. As industries demand more robust solutions, innovative approaches are necessary to address these limitations and enhance the overall functionality of split body ball valves. Adopting modern materials and design techniques can significantly improve durability and performance, paving the way for a new era in valve technology.

Emerging innovations in split body ball valve technology are transforming the landscape of fluid control across various industries. Recent advancements focus on enhancing the performance and reliability of these critical components. Innovative materials, such as advanced polymers and composite materials, have been integrated into valve designs to improve durability while reducing weight. This evolution ensures a longer lifespan and minimized maintenance costs, making split body ball valves more cost-effective in the long run.

Another significant trend is the incorporation of smart technology into split body ball valves. Manufacturers are now developing valves equipped with IoT capabilities that allow for real-time monitoring and automated control systems. This data-driven approach enables operators to optimize system performance, detect leaks or faults early, and enhance overall operational efficiency. As industries continue to seek greater precision and control in their processes, these technological advancements promise to set a new standard for fluid management solutions.

In the realm of industrial valve solutions, innovative approaches to split body ball valves have led to remarkable success stories across various applications. For instance, a recent report from the Valve Manufacturers Association (VMA) indicated that the adoption of advanced materials in split body ball valves has improved operational efficiency by up to 25%. This shift not only enhances durability but also reduces maintenance costs, allowing industries such as oil and gas, water treatment, and chemical processing to maximize their productivity.

One notable case study involves a major oil refinery that implemented a new design of split body ball valves featuring automated control systems. After transitioning to these innovative solutions, the refinery reported a 30% decrease in valve failures and downtime, translating to significant cost savings. Such improvements demonstrate the crucial role of innovative technology in enhancing reliability and performance, especially in environments with high pressure and severe corrosion challenges. As industries continue to embrace these cutting-edge solutions, the future of split body ball valves looks promising, driven by ongoing advancements and successful applications.

This bar chart illustrates the performance efficiency of different designs of split body ball valves. As seen, the new designs significantly outperform the traditional design, showcasing the impact of innovative approaches in this field.

When considering the effectiveness of various valve types in industrial applications, split body ball valves stand out due to their unique design and functionalities. Unlike traditional valves, which often require complete disassembly for maintenance, split body valves allow for easy access to internal components without removing the entire valve from the pipeline. This ease of maintenance can significantly reduce downtime and labor costs, making them an attractive choice for operational efficiency.

Furthermore, compared to gate or globe valves, split body ball valves offer superior flow characteristics. The spherical design creates minimal turbulence and pressure drop, enhancing flow rates and overall system performance. In contrast, gate valves can introduce more friction, while globe valves often restrict flow due to their design. This comparative advantage makes split body ball valves ideal for applications demanding high flow capacity and quick response times, particularly in oil and gas, water treatment, and chemical processing industries.

As industries around the world continue to prioritize efficiency and sustainability, the development of split body ball valves is undergoing a significant transformation. Future trends indicate a shift towards innovations that enhance not only the performance of these valves but also their environmental impact. One of the most promising advancements is the integration of smart technology, enabling real-time monitoring and automated adjustments. This capability allows for optimized flow control and leak detection, making systems more reliable and reducing maintenance costs.

Another key trend is the use of advanced materials and manufacturing techniques, such as 3D printing and composite materials, which improve the durability and lifespan of split body ball valves. These materials can withstand extreme conditions while minimizing weight, leading to more efficient installations and reducing the overall carbon footprint. Additionally, as regulatory standards tighten globally, the push for compliant and eco-friendly designs is stronger than ever. Manufacturers are focusing on producing valves that not only meet these requirements but also contribute to the overall sustainability goals of their clients, thus aligning with the increasing demand for greener solutions in the industrial sector.

| Feature | Current Trends | Future Developments | Benefits |

|---|---|---|---|

| Materials Used | Stainless Steel, Plastic Composites | Advanced Alloys, Eco-friendly Materials | Increased Durability, Environmental Compliance |

| Actuation Technology | Manual and Pneumatic Actuators | Smart Electric Actuators with IoT Integration | Remote Monitoring, Improved Operational Efficiency |

| Design Innovations | Standard Split Body Designs | Customizable Split Body Configurations | Greater Flexibility, Customized Solutions |

| Sealing Technology | Traditional Gaskets | Advanced Sealing Materials and Designs | Enhanced Leak Prevention, Longer Lifespan |

| Market Trends | Focus on Reliability and Cost-Effectiveness | Adoption of Sustainability Standards | Better Market Competitiveness, Regulatory Compliance |