-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

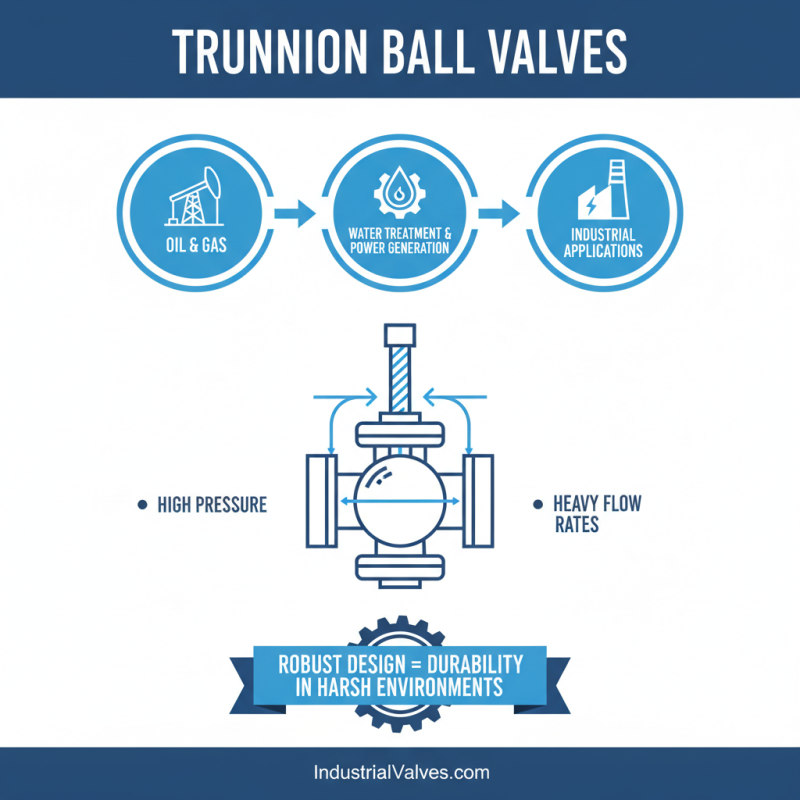

Trunnion Ball Valves play a crucial role in industrial applications. These valves are designed for high-pressure environments, ensuring reliability and safety. According to a recent report by Markets and Markets, the global industrial valve market is projected to reach $94.5 billion by 2025. Trunnion ball valves comprise a significant portion of this growth.

The importance of Trunnion Ball Valves lies in their ability to handle large flow rates. Industries such as oil and gas rely on these valves for efficient operation. In fact, 70% of oil and gas industries utilize this type of valve for their pipelines. They provide minimal pressure drop, which is essential to maintain system efficiency. However, not all installations meet the required standards.

Common challenges include improper installation and insufficient maintenance. Trunnion Ball Valves can suffer from wear and tear over time, affecting performance. This highlights the need for regular inspections and upgrades to ensure optimal functionality. Businesses must prioritize these aspects to prevent costly downtimes and ensure compliance with safety regulations. As industries evolve, adapting to new technologies and practices will be essential for harnessing the full potential of Trunnion Ball Valves.

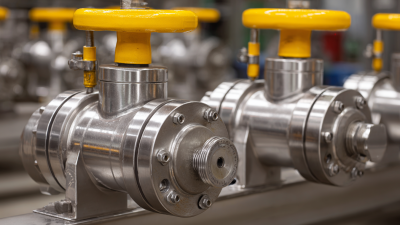

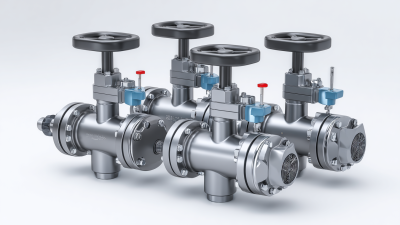

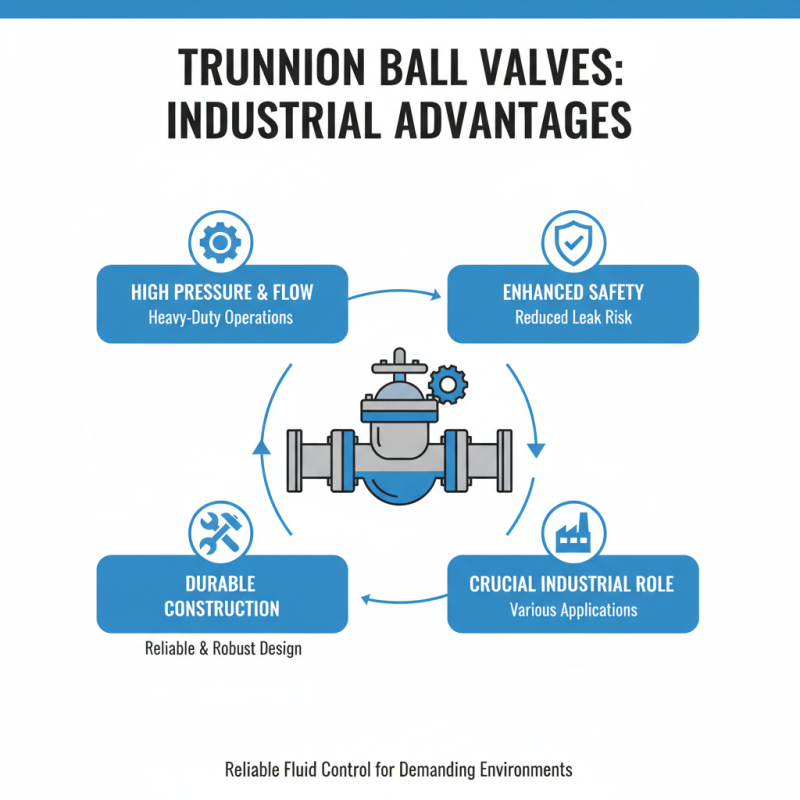

Trunnion ball valves play a critical role in industrial applications. They are designed to manage high pressures and heavy flow rates. This makes them ideal for sectors like oil and gas, water treatment, and power generation. Their robust design offers durability, which is crucial in harsh environments.

One key aspect is their ability to handle vibrations. In high-stress situations, these valves maintain functionality. However, over time, wear and tear may occur. Regular maintenance can help mitigate this issue. Operators sometimes overlook this aspect, possibly leading to failures.

Another significant feature is the ease of operation. These valves can be actuated easily, allowing for quick response in dynamic systems. Still, not all operators fully understand their complexities. Mismanagement can lead to inefficiencies. Ensuring proper training for staff on valve operation is imperative. In industrial settings, efficiency directly impacts productivity and safety.

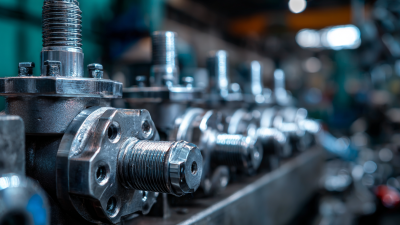

Trunnion ball valves offer unique design features that enhance performance in industrial applications. They have a mounted ball, which allows for minimal friction. This design helps in reducing wear and tear on the valve. It also ensures a tight seal, even under high pressure. As a result, trunnion ball valves are ideal for demanding environments.

One notable feature is their ability to manage flow control. This capability is essential in processes that require precision. The valve’s design allows for easy installation and maintenance. Operators can rely on them for consistent performance. However, it’s essential to note that improper use may lead to issues.

Tips: Regular inspection and maintenance can prevent unexpected failures. Ensure that the valve is matched to its intended application. Consider environmental factors, as they can impact valve performance. Regularly review operational parameters to keep everything in check.

Trunnion ball valves play a vital role in various industrial applications. Their design allows for reduced torque and increased stability, making them perfect for high-pressure environments. According to industry analysis, about 25% of valve failures are due to improper selection for specific applications. This emphasizes the importance of choosing the right valve, including trunnion types, for reliable operations.

In the oil and gas sector, trunnion ball valves are essential. They handle extreme pressures, often exceeding 10,000 psi. Studies indicate that the valve failure rate can lead to costs over $50 million annually. This illustrates the critical need for robust materials and designs in valve construction. Additionally, in the chemical industry, these valves improve safety and efficiency. Processes involving corrosive substances benefit from durable trunnion ball valves that provide leak-tight sealing.

Trunnion ball valves also find applications in water treatment facilities. These systems demand reliable isolation to prevent contamination. However, maintenance remains a challenge. Data shows that up to 30% of valve issues arise from inadequate maintenance practices. This highlights the need for regular performance evaluations. Despite their advantages, proper training and knowledge are essential to ensure optimal usage in all settings.

Trunnion ball valves play a crucial role in industrial applications. Their design provides significant advantages over other valve types. One key benefit is their ability to handle high pressures and large flow rates. This makes them ideal for heavy-duty operations. Their sturdy construction reduces the risk of leaks, which is vital for safety.

Another benefit is their reduced operating torque. Trunnion valves require less force to open and close. This feature can lead to lower energy costs over time. Additionally, these valves offer excellent sealing capabilities, which prevents fluid loss. This is especially important in industries where precision is essential.

However, it’s important to acknowledge some challenges. Trunnion ball valves may require more maintenance due to their complex design. They can be more expensive upfront compared to simpler valve types. Transitioning to this technology may require staff training. Despite these considerations, the benefits they provide often outweigh the drawbacks. Ultimately, careful evaluation is needed when selecting the right valve for specific applications.

Trunnion ball valves are essential in many industrial applications. However, proper maintenance is crucial to ensure their reliability. Regular inspections can prevent malfunction. Operators should check for leaks, alignment, and debris. Even minor issues can escalate quickly. Ignoring them may lead to costly downtime.

During maintenance, consider the environment too. Extreme temperatures or corrosive gases can impact valve performance. Operators often overlook this factor. Documenting conditions can help predict valve wear. Scheduled maintenance is not just a routine; it's a necessity.

Even after careful planning, errors can happen. Sometimes, the seals may degrade faster than expected. Having a backup plan is wise. Train staff on emergency repairs and valve replacements. This preparation can save resources and time in critical situations. Regularly revisiting maintenance protocols helps identify gaps. It encourages a culture of continuous improvement.

| Dimension | Description | Frequency of Maintenance | Common Issues | Impact on Operations |

|---|---|---|---|---|

| Operating Pressure | Maximum pressure the valve can handle | Annual | Leakage | Can lead to process inefficiencies |

| Temperature Range | Operating temperature limits | Semi-Annual | Seal failure | Process interruption |

| Stem Integrity | Condition of the valve stem | Quarterly | Corrosion | Potential for valve failure |

| Actuator Functionality | Performance of the actuator mechanism | Monthly | Sticking or jamming | Reduced operational efficiency |

| Ball Surface Condition | Sign of wear or damage on the ball surface | Annual | Surface cracks | Risk of contamination |