-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

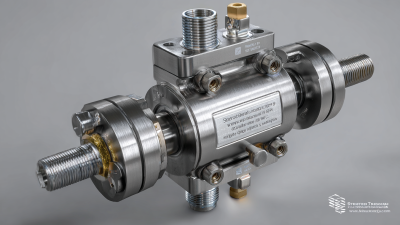

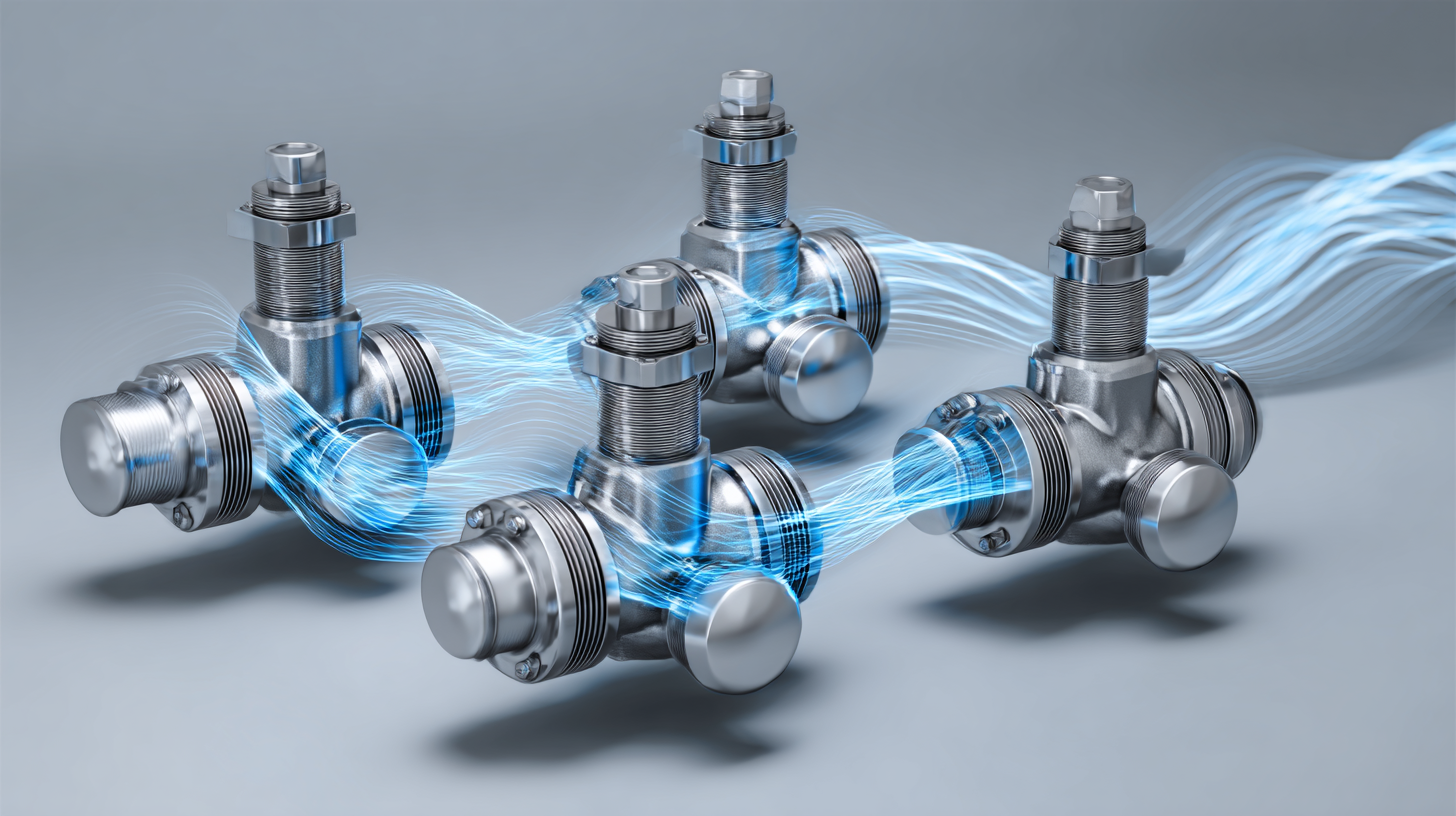

In the realm of fluid dynamics, the selection of components directly influences system efficiency and performance. Among various flow control devices, ball valves hold a significant position due to their unique design and operational advantages. Understanding the impact of ball valves on fluid flow is crucial, as these valves not only regulate the passage of fluids but also affect pressure drops, flow rates, and overall system dynamics. This article delves into the characteristics of ball valves, exploring their functionality, types, and how they interact with different fluid systems. By examining the operational principles and advantages inherent in these valves, we will shed light on their pivotal role in enhancing system efficiency and maintaining optimal performance in various industrial applications. Through this exploration, we aim to provide a comprehensive understanding of why ball valves are essential components in the design and management of fluid systems.

Ball valves play a crucial role in modulating fluid flow efficiency within piping systems. Their design allows for quick and reliable on-off control, minimizing pressure drops and energy losses often associated with other valve types. By providing a straight-through flow path, ball valves ensure that fluid dynamics are optimized, which is essential in industrial applications where efficiency directly correlates with operational costs and overall system performance.

When considering the implementation of ball valves in your piping system, it's important to focus on compatibility with fluid types and operating pressures. Regular maintenance is also vital; inspecting seals and seats can prevent leakage and maintain optimal flow rates.

**Tips:** Always select a ball valve with the appropriate material for your specific fluid to ensure longevity and prevent corrosion. Furthermore, consider the size and type of actuator if automation is required, as these factors can significantly impact flow efficiency and overall system performance.

The flow coefficient (Cv) and pressure drop across ball valves are critical parameters that dictate their impact on fluid dynamics and overall system efficiency. The flow coefficient quantifies the valve's ability to allow fluid to pass through it, making it essential for determining the appropriate valve selection for a specific application. A higher Cv value indicates that the valve can handle greater flow rates with less pressure loss, thus enhancing operational efficiency.

Conversely, the pressure drop is the difference in pressure between the inlet and outlet of the valve. It is influenced by various factors, including valve design, size, and the flow rate. Excessive pressure drop can lead to reduced system performance, increased energy consumption, and potential equipment wear. Therefore, understanding the relationship between the flow coefficient and pressure drop is vital for engineers and designers when optimizing fluid systems, ensuring they select the right ball valve that balances flow requirements with minimal energy loss.

This chart displays the impact of different ball valves on fluid dynamics by analyzing the pressure drop in psi and the flow coefficient (Cv). The data highlights how each valve performs under comparable conditions, enabling better decisions for system efficiency.

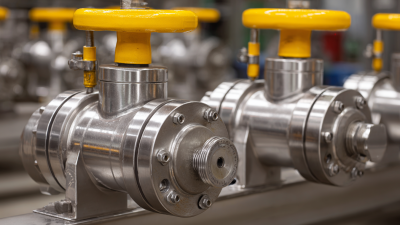

Ball valves are critical components in fluid transport systems, significantly influencing energy consumption and overall efficiency. Their design affects how fluid flows through pipelines, with streamlined configurations minimizing turbulence and pressure losses. When a ball valve is opened, the flow path becomes unobstructed, allowing for minimal energy loss compared to other valve types. This design consideration is paramount, particularly in applications dealing with high-pressure fluids where even slight inefficiencies can lead to substantial energy expenditures.

Furthermore, the materials and sealing mechanisms used in ball valve construction play a key role in their impact on energy consumption. High-quality materials that reduce friction can enhance flow rates and reduce the energy required to move fluids through the system. Additionally, well-designed sealing features prevent leakages, ensuring that energy is not wasted. Ultimately, investing in optimized ball valve designs not only promotes energy efficiency but also leads to long-term cost savings in fluid transport systems, making them a smart choice for industries reliant on efficient fluid management.

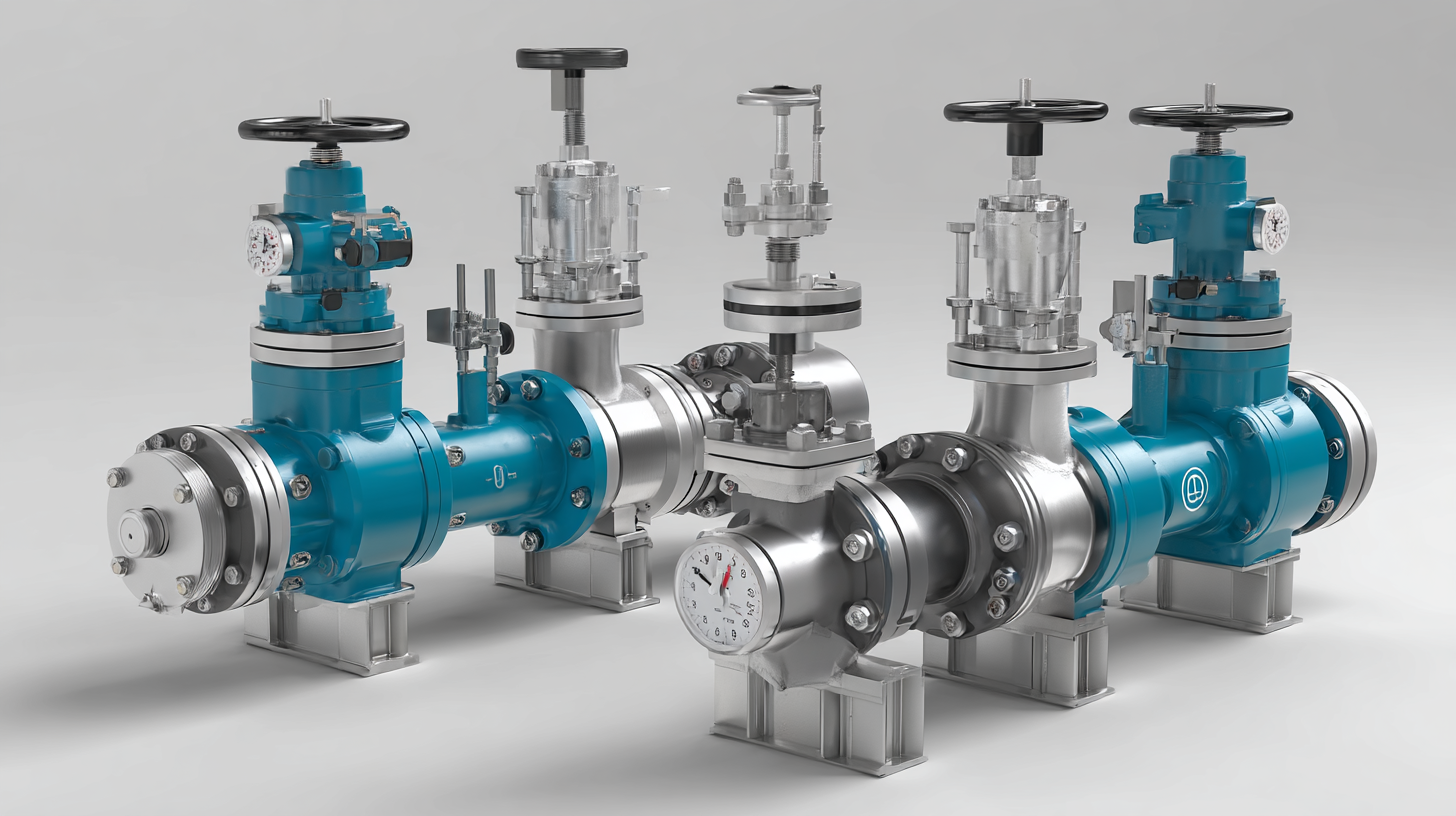

In the industrial valve market, ball valves and gate valves are commonly used to control fluid flow, yet their performance can markedly differ. According to a report by MarketsandMarkets, the global valve market is expected to reach USD 81.6 billion by 2025, highlighting the growing importance of selecting the right valve type for enhanced operational efficiency. Ball valves, favored for their quick shut-off capabilities, achieve a flow coefficient (Cv) significantly higher than gate valves, which can suffer from flow restrictions when partially open. In fluid systems where efficiency is paramount, the choice of valve can directly impact energy consumption and overall process performance.

Tip: When selecting valves for your industrial application, consider the specific flow requirements and operating pressures. Ball valves are often more suitable for high flow rates due to their lower pressure drops, while gate valves may work better in applications requiring a full-open or full-closed position.

Tip: When selecting valves for your industrial application, consider the specific flow requirements and operating pressures. Ball valves are often more suitable for high flow rates due to their lower pressure drops, while gate valves may work better in applications requiring a full-open or full-closed position.

Furthermore, reliability and maintenance should also be considered. Ball valves typically have a longer lifespan and require less maintenance than gate valves, especially in high-cycle applications. A study from the American Society of Mechanical Engineers (ASME) demonstrates that switching from gate to ball valves can reduce maintenance costs by up to 30%, reflecting not only on operational budgets but also on system downtime.

Tip: Regular maintenance checks can optimize the lifespan of both valve types. Implementing a preventive maintenance schedule ensures that any potential issues are addressed before they lead to costly repairs or replacements.

When selecting a ball valve for your fluid system, it’s crucial to consider the specific needs of your application to enhance overall performance and efficiency. According to a report by the American Society of Mechanical Engineers (ASME), proper valve selection can improve system efficiency by up to 15%. Factors such as nominal size, pressure rating, and material compatibility with the fluid media are paramount. For instance, high-performance ball valves made from stainless steel are preferred in corrosive environments, ensuring longevity and minimal maintenance.

Tips: Always assess the flow rate requirements of your system. A valve that is too large can lead to turbulence and pressure drops, while one that is too small can restrict flow and increase operating costs. Furthermore, consider the operating temperature and pressure when selecting materials, as these can significantly impact valve performance.

In addition, be aware of the valve's design features. Trunnion-mounted ball valves provide greater stability and are ideal for high-pressure applications. A report from the Valve Manufacturers Association (VMA) indicates that using the right type of ball valve can reduce energy consumption by as much as 20% in certain systems. Prioritizing these criteria will not only ensure reliability but also optimize your system's fluid dynamics.