-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In industrial applications, the efficiency of valve systems is paramount. High Temperature Ball Valves stand out due to their durability and reliability. According to industry expert John Smith, "Using the right valve can enhance system performance significantly." These valves are designed to withstand extreme conditions, making them ideal for various processes.

High Temperature Ball Valves provide crucial advantages but demand careful consideration. They are often more expensive than standard valves. The choice depends on specific application needs. Different materials and designs can affect their performance. Thermal expansion may cause issues if not accounted for.

Experts suggest comparing options before making a decision. Many industries benefit from High Temperature Ball Valves, but each application has unique challenges. Performance under pressure can vary. Understanding both strengths and limitations is critical for successful implementation.

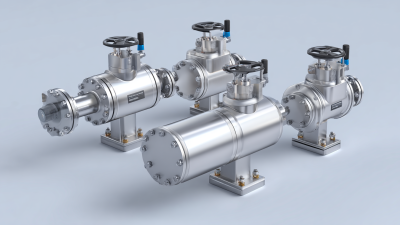

High temperature ball valves are essential in various industrial applications. They perform well in extreme conditions and maintain process integrity. These valves can handle high-pressure and high-temperature fluids without failing. This reliability makes them a preferred choice in many sectors, including oil and gas, chemicals, and power generation.

Using high temperature ball valves can boost efficiency. Their design allows for quick action, minimizing downtime during operations. The tight sealing prevents leaks, which is crucial in sensitive processes. Additionally, these valves require less maintenance compared to traditional options. This factor translates into lower operational costs over time.

**Tip:** Regularly inspect your high temperature ball valves. Look for wear and tear signs. Even the best valves can develop issues if not monitored.

Another benefit is their versatility. High temperature ball valves work well with different media, including corrosive substances. However, not all applications may require high-temperature capability. Assess your specific needs before making a decision.

**Tip:** Evaluate fluid characteristics before selecting a valve. Matching the valve to the application can prevent costly mistakes. Keeping an open mindset about different valve types may lead to better outcomes.

| Feature | Description | Benefits |

|---|---|---|

| Temperature Range | -50°F to 800°F (-45°C to 427°C) | Suitable for high-temperature environments |

| Material | Typically Stainless Steel or High Alloy Materials | Enhanced durability and corrosion resistance |

| Sealing Mechanism | PTFE, PEEK, or other High-Temperature Sealants | Reliable sealing even under extreme temperatures |

| Applications | Oil and Gas, Power Generation, Chemicals | Wide range of industrial applications |

| Maintenance | Low maintenance requirement | Cost-effective over the long term |

| Safety | Designed to withstand high pressure | Increased safety for operators and equipment |

High temperature ball valves are critical in industrial applications requiring reliability and efficiency. These valves typically handle temperatures exceeding 200°C (392°F). They ensure seamless operation in sectors like oil and gas, chemical processing, and power generation. In these industries, a small failure can lead to significant production losses or safety hazards.

One vital feature of high temperature ball valves is their robust materials. They are often made of stainless steel or specialized alloys. This construction withstands thermal stress and corrosion. Research shows that using these materials can extend valve life by up to 25%. Moreover, close tolerances and advanced sealing technologies minimize leaks. According to industry reports, leakage can decline by over 50% with modern designs. The improved reliability ultimately enhances overall system efficiency.

Yet, there are challenges. Some installations may not consider thermal expansion. This oversight can lead to valve failure or excessive maintenance costs. Additionally, precise installation is essential. Misalignment or improper support can hinder performance. Operators should conduct regular inspections to catch these issues early. Keeping a close eye on operational conditions is necessary. The stakes are high in high-temperature applications, and poor decisions can be costly.

When selecting materials for high temperature ball valves, durability is key. Common choices include stainless steel and specialized alloys. Stainless steel offers good strength and corrosion resistance. However, it can struggle under extreme heat. Specialized alloys often withstand higher temperatures but may be more expensive.

High temperatures can cause some materials to weaken or degrade. The selection process should consider exact operating conditions. For instance, a valve exposed to steam may require different materials than one handling hot oil. Testing materials for thermal expansion and contraction is crucial. Some materials might shatter or deform when exposed to rapid temperature changes.

In high temperature environments, sealing materials also matter. Traditional elastomers might fail, leading to leaks. Choosing the wrong material could result in valve failure and costly downtime. Manufacturers must balance cost, availability, and performance. A thorough understanding of each material's properties helps ensure reliability.

High temperature ball valves play a crucial role in various industrial settings. They are designed to withstand extreme heat and pressure. This makes them ideal for industries such as oil and gas, petrochemical, and power generation. In the oil and gas sector, these valves manage hot fluids and gases. They ensure safety and efficiency in operations.

Another important application is in the petrochemical industry. High temperature ball valves control chemical processes that occur at elevated temperatures. They help maintain proper flow rates and prevent leaks. Similarly, in power plants, they regulate steam and hot water flows. Their durability is essential for maintaining overall system integrity.

Tips: Always consider valve material. It should resist corrosion and wear at high temperatures. Regular maintenance is vital. Check for signs of wear to avoid unexpected failures. Training staff on valve operation can prevent misuse. A simple mistake can lead to costly downtime.

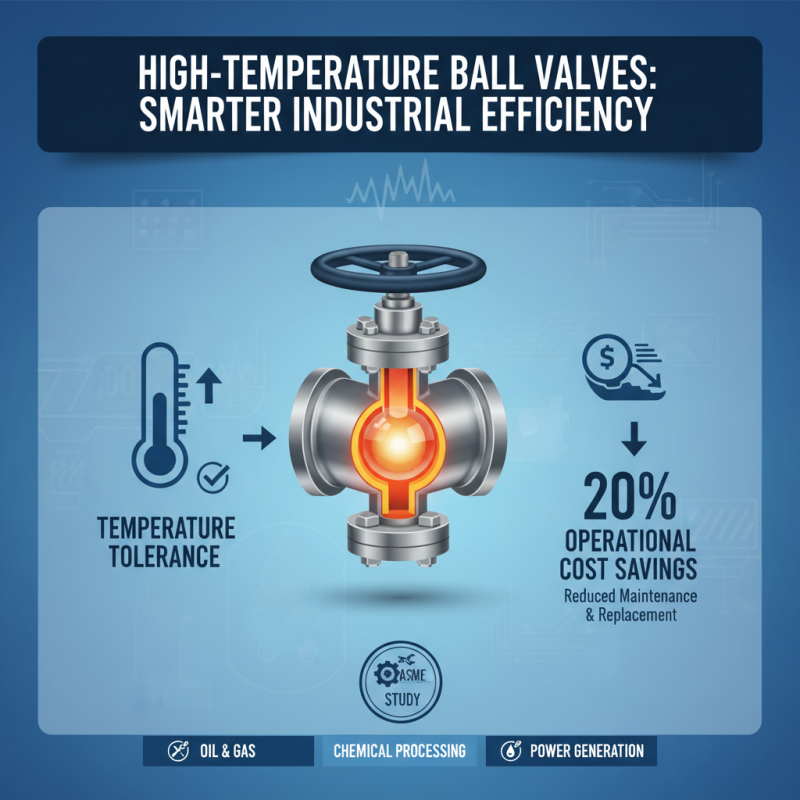

High temperature ball valves are gaining traction in various industrial sectors. Their efficiency goes beyond mere temperature tolerance. A study from the American Society of Mechanical Engineers highlights that using high temperature ball valves can lead to operational cost savings of up to 20% over time. This can significantly reduce maintenance and replacement costs, crucial in industries like oil and gas.

When it comes to durability, high temperature ball valves outperform standard alternatives. They typically have an extended lifespan of up to 50% longer. However, one must recognize that installation costs can be higher initially. This upfront investment may deter some industries from opting for high temperature solutions. Yet, the longevity of these valves often justifies the initial expense.

In high-stakes environments, failure is not an option. Safety concerns arise when choosing the wrong components. Reports indicate that improper valve selection can lead to process leaks and costly downtimes. The benefits of high temperature ball valves extend into safety improvements, reducing risk factors associated with traditional valves. Investing wisely in these valves is essential for long-term efficacy and cost management.