-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the realm of industrial applications, the demand for high-performance components has led to the evolution of advanced technologies, notably in the design of High Temperature Ball Valves. According to a report by Market Research Future, the global market for ball valves is expected to reach USD 8.2 billion by 2025, driven significantly by their use in high-temperature and high-pressure environments. These valves play a crucial role in sectors such as oil and gas, chemical processing, and power generation, where operational reliability and efficiency are paramount. Understanding the design intricacies of High Temperature Ball Valves not only enhances their operational performance but also addresses the increasing challenges posed by extreme thermal conditions. As industries continue to push the boundaries of operational temperatures, it becomes essential to explore how these valves are engineered to withstand such conditions while ensuring safety and longevity in critical applications.

In the realm of industrial applications, the demand for high-performance components has led to the evolution of advanced technologies, notably in the design of High Temperature Ball Valves. According to a report by Market Research Future, the global market for ball valves is expected to reach USD 8.2 billion by 2025, driven significantly by their use in high-temperature and high-pressure environments. These valves play a crucial role in sectors such as oil and gas, chemical processing, and power generation, where operational reliability and efficiency are paramount. Understanding the design intricacies of High Temperature Ball Valves not only enhances their operational performance but also addresses the increasing challenges posed by extreme thermal conditions. As industries continue to push the boundaries of operational temperatures, it becomes essential to explore how these valves are engineered to withstand such conditions while ensuring safety and longevity in critical applications.

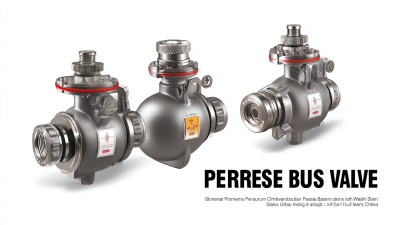

High temperature ball valves are essential components in various critical applications, such as those found in the oil and gas, chemical processing, and power generation industries. These valves are specifically designed to withstand extreme temperatures, ensuring reliable performance under challenging conditions. One of the key features of high temperature ball valves is their robust construction, typically using high-grade materials like stainless steel or special alloys that provide resistance to thermal expansion and corrosion. This durability enhances their longevity and reduces maintenance costs, making them ideal for demanding operational environments.

Another important aspect of high temperature ball valves is their sealing mechanism. Advanced seal materials, such as PTFE or graphite, are utilized to maintain optimal sealing integrity even at elevated temperatures. This ensures that the valves can operate with minimal leakage, which is crucial in applications where safety and environmental protection are paramount. Additionally, the design of these valves often includes blow-out proof stems to enhance safety, ensuring that the stem does not dislodge under high pressure or temperature changes. Overall, these features collectively contribute to the enhanced functionality and reliability of high temperature ball valves in critical applications.

The selection of materials for high temperature ball valves is crucial to ensuring both

durability and optimal performance in critical applications. High temperatures often lead to material degradation; therefore,

choosing alloys and composites that can withstand thermal stress becomes paramount. Common materials used include

stainless steel and specialized high-alloy steels, which offer excellent

resistance to oxidation and corrosion at elevated temperatures. Additionally, materials such as nickel-based superalloys

can provide superior mechanical properties and stability, making them ideal for extreme conditions.

The selection of materials for high temperature ball valves is crucial to ensuring both

durability and optimal performance in critical applications. High temperatures often lead to material degradation; therefore,

choosing alloys and composites that can withstand thermal stress becomes paramount. Common materials used include

stainless steel and specialized high-alloy steels, which offer excellent

resistance to oxidation and corrosion at elevated temperatures. Additionally, materials such as nickel-based superalloys

can provide superior mechanical properties and stability, making them ideal for extreme conditions.

Incorporating advanced seal technologies also plays a significant role in enhancing the performance of high temperature ball valves.

Seals must be made of materials that can endure high thermal loads while maintaining their integrity to prevent leaks.

Fluoropolymer-based seals are popular for their exceptional heat resistance

and low friction characteristics, helping to improve the valve's efficiency. Ultimately, the right combination of materials not only

enhances the mechanical performance of high temperature ball valves but also extends their service life, making them reliable components

in demanding industrial settings.

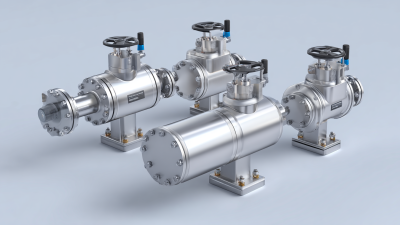

When designing high-temperature ball valves for critical applications, several vital considerations must be addressed to enhance reliability and performance. Materials used in the construction of these valves, such as specially formulated alloys or advanced composites, are pivotal. According to a report by the American Society of Mechanical Engineers (ASME), the right material selection can significantly improve the valve's resistance to thermal stresses and corrosion, extending its service life in operations exceeding 300°C.

Another critical factor is the valve's sealing mechanisms. In high-temperature environments, traditional seals may degrade rapidly, leading to leaks and potential failures. Innovative sealing technologies, such as metal-to-metal seals or high-performance elastomers, have been shown to withstand extreme temperatures while maintaining integrity. A study published in the Journal of Valve Engineering highlights that valves equipped with advanced sealing solutions can reduce leak rates by up to 95% compared to standard designs, greatly enhancing operational reliability in demanding conditions.

Furthermore, valve design must account for thermal expansion and contraction. As temperatures fluctuate, the mechanical components of the valve can experience stress that, if not properly managed, could lead to malfunction. Employing robust design principles, including modular designs that allow for thermal movement and expansion joints, can mitigate these risks significantly. Industry data indicates that valves designed with these considerations can achieve operational efficiencies of over 90%, solidifying their role in industries where reliability is paramount.

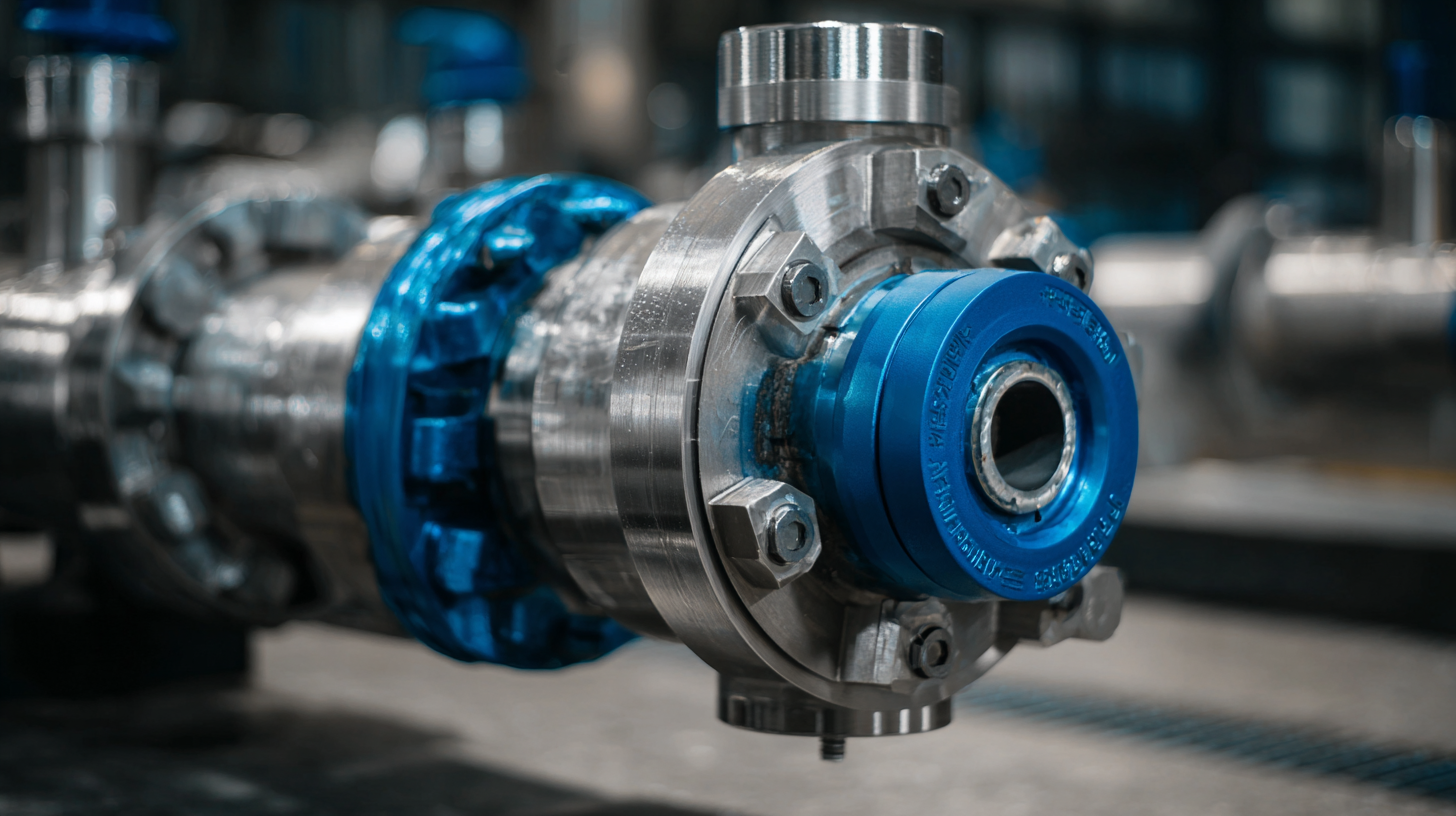

Quality assurance is critical for high-temperature ball valves, especially given their applications in industries like oil and gas, power generation, and chemical processing. These valves must maintain integrity and performance under extreme thermal conditions, often exceeding 500°F (260°C). Recent advancements in testing methodologies have highlighted the importance of rigorous quality control processes. For instance, non-destructive testing (NDT) techniques, such as X-ray fluorescence (XRF), enable manufacturers to assess material composition without compromising the integrity of the valve. This ensures that the materials used can withstand the harsh environments often encountered in critical applications.

Moreover, industry reports indicate that the failure rates of valves operating in high-temperature environments can significantly impact operational efficiency. A study revealed that improperly tested valves account for nearly 30% of failures in critical systems, leading to costly shutdowns and maintenance. Implementing comprehensive testing protocols, which may include pressure testing and thermal cycling, ensures that each valve meets the rigorous demands before installation. Innovative approaches in quality assurance not only enhance product reliability but also align with evolving industry standards, ultimately contributing to the safety and effectiveness of various high-stakes applications.

When it comes to high temperature ball valves, proper installation and maintenance are crucial for maximizing their longevity, especially in critical applications such as oil and gas, power generation, and chemical processing. According to a report by the Global Valves Market, improper installation can lead to performance issues, reducing the lifespan of a valve by up to 30%. Therefore, ensuring that the valve is installed at the right angle and that all connections are tight can prevent leaks and operational failures.

Routine maintenance practices, such as regular inspection and flushing, significantly contribute to the durability of ball valves. The American Society of Mechanical Engineers (ASME) recommends a maintenance schedule that includes visual inspections every six months and comprehensive testing annually. This proactive approach not only identifies potential wear and tear early but also helps maintain optimal seal integrity. Furthermore, using compatible lubricants and ensuring that valve seats remain clean can enhance performance and efficiency by up to 20%, reducing the risk of unexpected downtime in critical operations.