-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the ever-evolving landscape of industrial applications, the importance of efficient fluid control systems cannot be overstated. Among the myriad of options available, Screwed Ball Valves have emerged as a key component in facilitating precise flow regulation in various sectors, including oil and gas, chemical processing, and water treatment. According to a recent market analysis by Grand View Research, the global ball valve market is projected to reach $10.8 billion by 2027, with a significant portion attributable to the increasing demand for Screwed Ball Valves in high-pressure applications due to their reliability and simplicity. This ultimate guide aims to provide a comprehensive understanding of Screwed Ball Valves, offering essential tips and insights that will enable you to make informed decisions for your specific applications, maximizing both efficiency and safety in your operations.

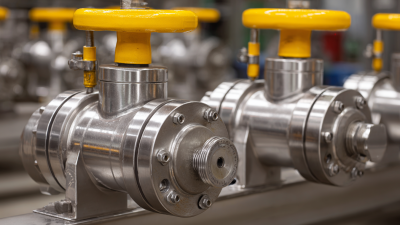

Screwed ball valves are essential components in various industrial applications, recognized for their reliability and efficiency. Understanding their anatomy and design features is crucial for effective implementation. Typically, these valves consist of a spherical disc that controls fluid flow, with a threaded connection that ensures a secure, leak-proof seal. According to a report by Global Market Insights, the ball valve market is projected to exceed $10 billion by 2027, driven by their increasing adoption across sectors like oil and gas, water treatment, and chemical processing.

Screwed ball valves are essential components in various industrial applications, recognized for their reliability and efficiency. Understanding their anatomy and design features is crucial for effective implementation. Typically, these valves consist of a spherical disc that controls fluid flow, with a threaded connection that ensures a secure, leak-proof seal. According to a report by Global Market Insights, the ball valve market is projected to exceed $10 billion by 2027, driven by their increasing adoption across sectors like oil and gas, water treatment, and chemical processing.

When selecting screwed ball valves, consider factors such as material compatibility and pressure ratings. For instance, valves manufactured from stainless steel or brass are ideal for corrosive environments, while PVC options serve well in less demanding applications. Tip: Always refer to manufacturer specifications to ensure the selected valve meets the required standards for pressure and temperature.

Design features play a pivotal role in performance. Many modern screwed ball valves include blowout-proof stems and full-port designs, which facilitate higher flow rates and better reliability. A survey conducted by the Valves and Actuators Committee revealed that 78% of professionals prioritize durability and maintenance ease when choosing ball valves. Tip: Regular maintenance checks can significantly extend the lifespan of these valves, preventing costly downtime in industrial operations.

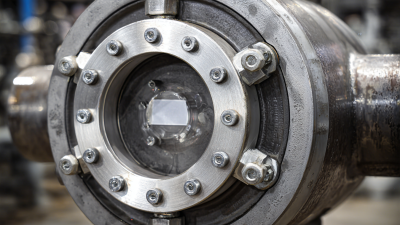

Screwed ball valves are an essential component in various industrial applications, offering a combination of reliability and efficiency. One of the key advantages of these valves is their simple design, which allows for easy installation and maintenance. The screwed connections provide a secure and leak-proof seal, reducing the risk of fluid leakage and ensuring system integrity. Furthermore, the ability to easily disassemble the valve makes routine inspections and repairs straightforward, minimizing downtime and enhancing operational efficiency.

Another significant advantage of screwed ball valves is their versatility across different media. They can handle a wide range of fluids, including gases, liquids, and even slurries, making them suitable for diverse industries such as oil and gas, water treatment, and chemical processing. Their modular nature allows them to be adapted for various applications, from controlling the flow in a pipeline to acting as a shut-off valve in critical processes. Additionally, the compact design of screwed ball valves allows for space-saving installations without compromising performance, making them a preferred choice for many engineers and operators.

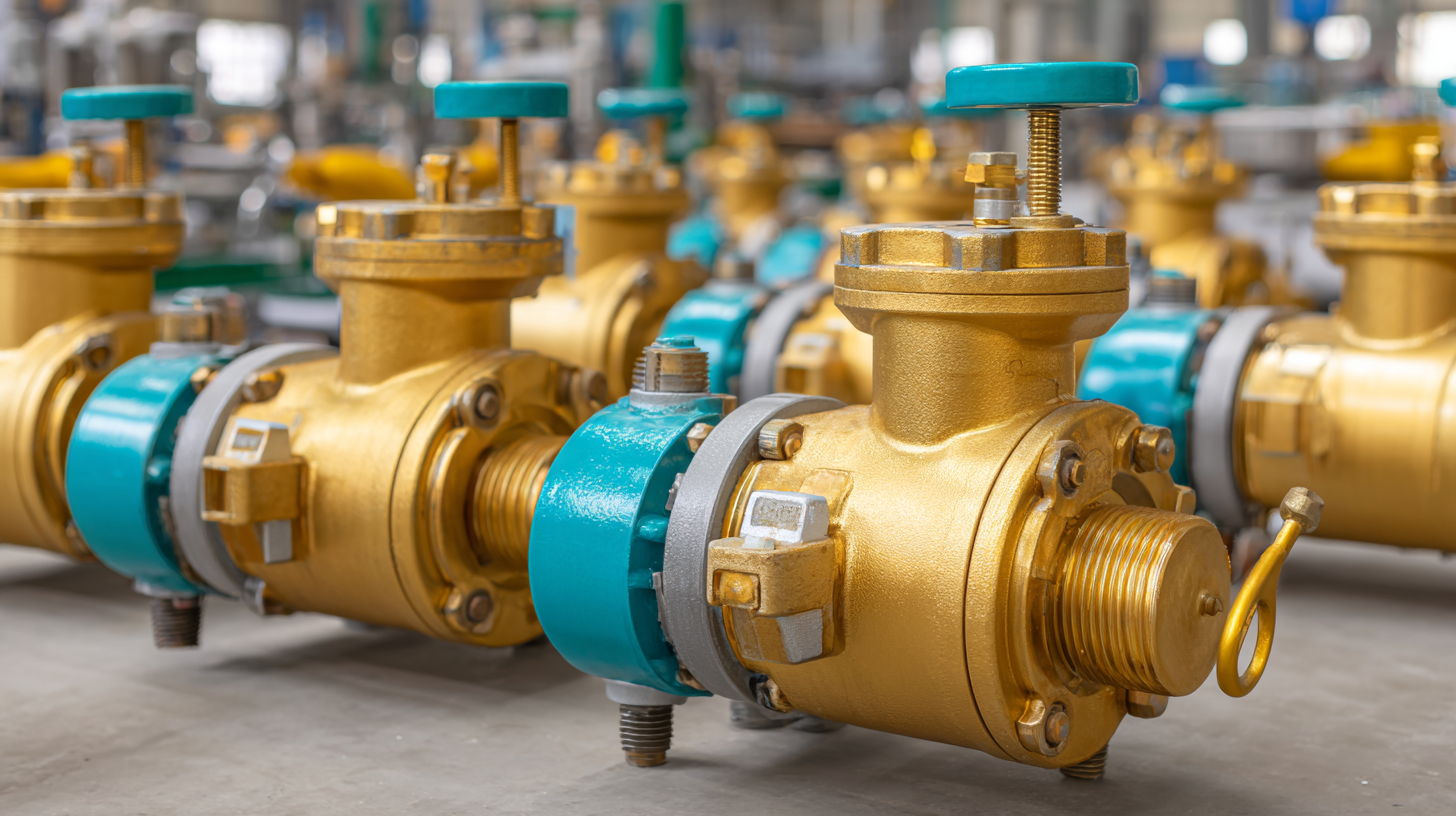

The market for screwed ball valves has been witnessing significant growth, driven by increased demand across various industries including oil and gas, water treatment, and food processing. According to a recent report by MarketsandMarkets, the global ball valve market is expected to reach USD 12.3 billion by 2026, with a compound annual growth rate (CAGR) of 5.4% from 2021. This growth can be attributed to the rising need for superior fluid control systems and improved operational efficiency.

Furthermore, a report from Technavio highlights that North America holds the largest market share for screwed ball valves, mainly due to the robust industrial infrastructure and the increasing adoption of automation in manufacturing processes. The demand for energy-efficient solutions has also prompted manufacturers to innovate, enhancing their product offerings with advanced materials and designs that cater to specific application requirements. As industries continue to evolve, the emphasis on sustainable practices will likely drive further advancements in valve technology, paving the way for more reliable and durable screwed ball valves in the market.

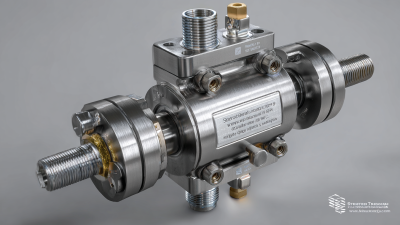

When it comes to choosing the right valve for industrial applications, performance metrics play a crucial role in making an informed decision. Screwed ball valves are renowned for their reliable performance, particularly in high-pressure and high-flow scenarios. Their design allows for minimal resistance to flow, translating to lower energy consumption and improved system efficiency. Unlike gate or globe valves, screwed ball valves offer a straightforward mechanism that enables quick opening and closing, making them ideal for processes requiring swift adjustments.

When compared to other valve types, such as gate, globe, and butterfly valves, screwed ball valves stand out due to their superior sealing capability and long lifespan. Unlike gate valves that can wear down over time and result in leaks, screwed ball valves provide a tight seal, minimizing the risk of fluid loss. Additionally, their simple operation and robustness often reduce maintenance needs, enhancing their overall cost-effectiveness. Analyzing these performance metrics helps engineers and operators select screwed ball valves over competitors, ensuring optimal performance and reliability in diverse applications.

When it comes to installing and maintaining screwed ball valves, industry best practices are essential for ensuring longevity and efficiency in applications, particularly in natural gas systems. Regular maintenance such as inspection for leaks and ensuring proper lubrication can significantly enhance the performance of these valves. According to industry reports, nearly 60% of failures in valve systems can be traced back to inadequate maintenance routines. Hence, adhering to a structured maintenance schedule can mitigate risks and optimize operational efficiency.

Proper installation techniques also play a critical role in the performance of screwed ball valves. It is crucial to install valves following manufacturer specifications, ensuring that the piping is properly supported and aligned. Research indicates that improper installation can lead to a 40% decrease in the service life of these valves. As natural gas infrastructure continues to expand, especially with the recent trends towards commissioning new gas-fired plants, maintaining these components with diligence becomes increasingly vital. Associations report that implementing best practices in valve maintenance can lead to a 20% reduction in operational costs, underscoring the economic benefits of thorough valve management strategies.