-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

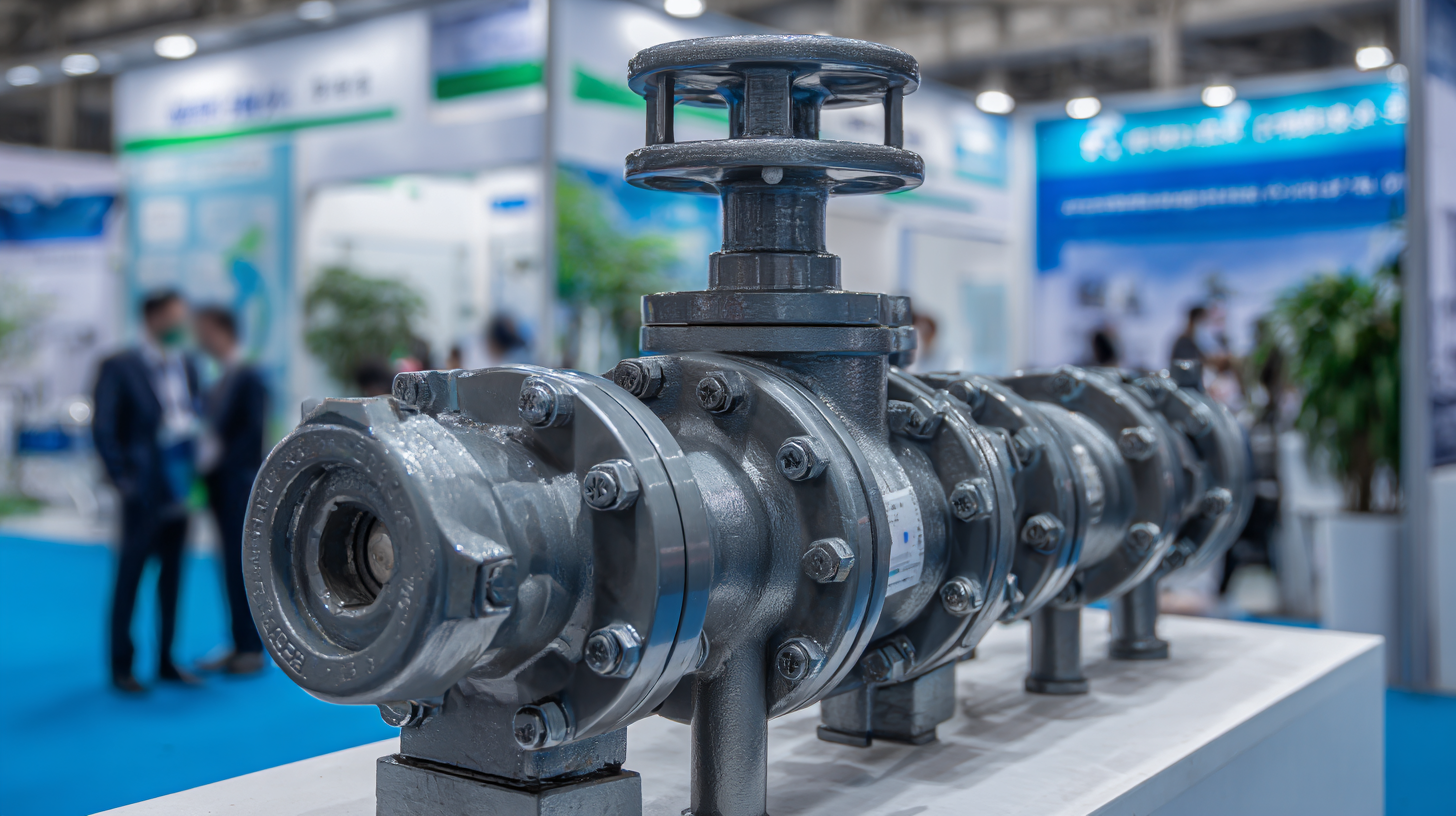

As the global industrial landscape continues to evolve, the Casting Ball Valve industry is poised for significant advancements, particularly showcased at the 138th China Import and Export Fair in 2025. This event promises to bring together innovative manufacturers, exporters, and customers, providing a platform for the latest technological breakthroughs and design enhancements in Casting Ball Valves. With a growing emphasis on sustainability and efficiency, the fair will highlight how these valves are adapting to meet modern demands in various applications, including water management, chemical processing, and energy sectors.

Attendees can expect insightful discussions on market trends, emerging challenges, and opportunities within the industry, positioning Casting Ball Valves as critical components in the future of industrial operations. By exploring these dynamics, stakeholders can better understand the role of Casting Ball Valves in a rapidly changing economic environment.

As the casting ball valve industry anticipates significant developments, the China Import and Export Fair in 2025 will serve as a crucial platform for unveiling emerging trends. Amid the global shift towards sustainable technologies, manufacturers are focusing on integrating eco-friendly materials and energy-efficient designs into their casting ball valves. This evolution not only responds to regulatory demands but also caters to the growing consumer preference for environmentally responsible products.

Furthermore, technological advancements play a vital role in shaping the future of this market. The incorporation of smart technology in casting ball valves, such as IoT capabilities, enhances operational efficiency and allows for real-time monitoring. This trend signifies a move towards more automated and intelligent systems, which can significantly reduce maintenance costs and improve reliability. Attendees of the fair can expect to engage with industry leaders who will showcase innovative solutions, providing valuable insights into how these advancements will redefine the standards and applications within the casting ball valve sector.

The casting ball valve industry is poised for significant transformation by 2025, driven primarily by technological advancements that enhance both production efficiency and valve performance. Innovations in materials science, such as the development of high-performance alloys and composites, are expected to address the durability and corrosion resistance challenges traditionally faced by ball valves. These advancements will not only extend the lifecycle of the valves but also reduce maintenance costs for end-users, making them a more attractive option in industrial applications.

Moreover, the integration of automation and data analytics in manufacturing processes is set to redefine how casting ball valves are produced. The use of 3D printing technologies allows for rapid prototyping and customized designs, facilitating an agile manufacturing process that can respond quickly to market demands. Furthermore, advanced simulation tools can optimize fluid dynamics within the valves, ensuring superior performance in various operational conditions. As the industry showcases these innovations at the China Import and Export Fair 138, stakeholders will gain valuable insights into how embracing these technologies can lead to enhanced efficiency and competitiveness in the global market.

The casting ball valve industry is undergoing significant transformation as it responds to the evolving demand and supply dynamics in both China and the global market. With the growing emphasis on industrial automation and efficiency, the adoption of advanced ball valve technologies is expected to rise. The upcoming China Import and Export Fair 138 in 2025 will serve as a pivotal platform for industry leaders to showcase innovative products, which will cater to the increasing requirements for durable and maintenance-friendly valve solutions in various sectors such as oil and gas, water treatment, and manufacturing.

Market analysis indicates a robust growth trajectory for casting ball valves, driven by strategic investments and advancements in manufacturing processes. Stakeholders are keen to understand the interplay between rising demand and supply chain challenges, including material shortages and logistics disruptions. Key players are focusing on enhancing their production capacities and expanding their product lines to capture emerging markets. This evolving landscape reflects both the challenges and opportunities that the casting ball valve sector faces, making it essential for industry participants to stay agile and responsive to market trends.

| Region | Demand (Units) | Supply (Units) | Growth Rate (%) | Key Markets |

|---|---|---|---|---|

| China | 500,000 | 450,000 | 5.0 | Oil & Gas, Water Supply |

| North America | 200,000 | 180,000 | 3.8 | Power Generation, Chemical Processing |

| Europe | 300,000 | 290,000 | 4.2 | Construction, Manufacturing |

| Asia-Pacific | 250,000 | 230,000 | 6.0 | Mining, Agriculture |

The 138th China Import and Export Fair in 2025 will spotlight significant innovations within the casting ball valve industry, particularly emphasizing sustainability. As global industries shift towards greener practices, the casting ball valve sector is poised to lead the way with eco-friendly manufacturing processes and materials. Innovations such as the use of recyclable alloys and energy-efficient production methods are expected to reduce the environmental footprint of valve manufacturing significantly.

Moreover, advancements in technology are enabling better design and efficiency in ball valves, contributing to sustainability goals. Smart manufacturing techniques, including the integration of IoT and AI, are set to revolutionize how these products are produced and maintained. By showcasing these innovations at the fair, the industry aims to foster greater awareness and adoption of sustainable practices. This shift not only benefits the environment but also enhances product durability and performance, making it a win-win for manufacturers and consumers alike.

The casting ball valve industry is poised for significant growth leading up to 2025, particularly as investment opportunities emerge amidst evolving market dynamics. As highlighted in recent reports, the industrial valve sector is witnessing an increased demand driven by various industries, including oil and gas, water treatment, and chemical processing. The strategic overview of investment opportunities reveals that understanding market trends and technological advancements will be crucial for stakeholders aiming to capitalize on this burgeoning sector.

However, alongside these opportunities, challenges remain. Companies need to navigate competition and keep pace with innovations in valve technology. The importance of quality and reliability will drive strategic investments in R&D to cater to the demanding specifications of end-users. Moreover, fluctuations in raw material prices and supply chain disruptions are potential hurdles that require careful attention. Stakeholders attending the China Import and Export Fair in 2025 will find a platform to discuss these challenges and explore collaborative strategies to enhance competitiveness in the casting ball valve market.