-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the modern industrial landscape, the choice of valve technology can significantly impact operational efficiency and safety. Forged Steel Ball Valves have emerged as a preferred option for many industries due to their robust construction, superior durability, and excellent sealing capabilities. According to a recent market analysis by Industry Research Insights, the global forged steel valve market is expected to grow at a CAGR of 5.6% from 2022 to 2029, driven by the increasing demand for high-performance valves in various sectors such as oil and gas, chemical processing, and power generation.

Experts emphasize the importance of selecting the right valve type for specific applications. Dr. Emily Carter, a recognized authority in fluid control systems, states, "Forged Steel Ball Valves are essential for ensuring reliable fluid management in critical industrial applications. Their strength and resilience make them ideal for environments that demand high pressure and temperature resistance." With their ability to withstand extreme conditions and provide a tight seal, forged steel ball valves not only enhance system reliability but also minimize maintenance needs, leading to reduced operational costs over time. Thus, understanding the advantages of Forged Steel Ball Valves is vital for making informed decisions that align with the growing demands of industrial applications.

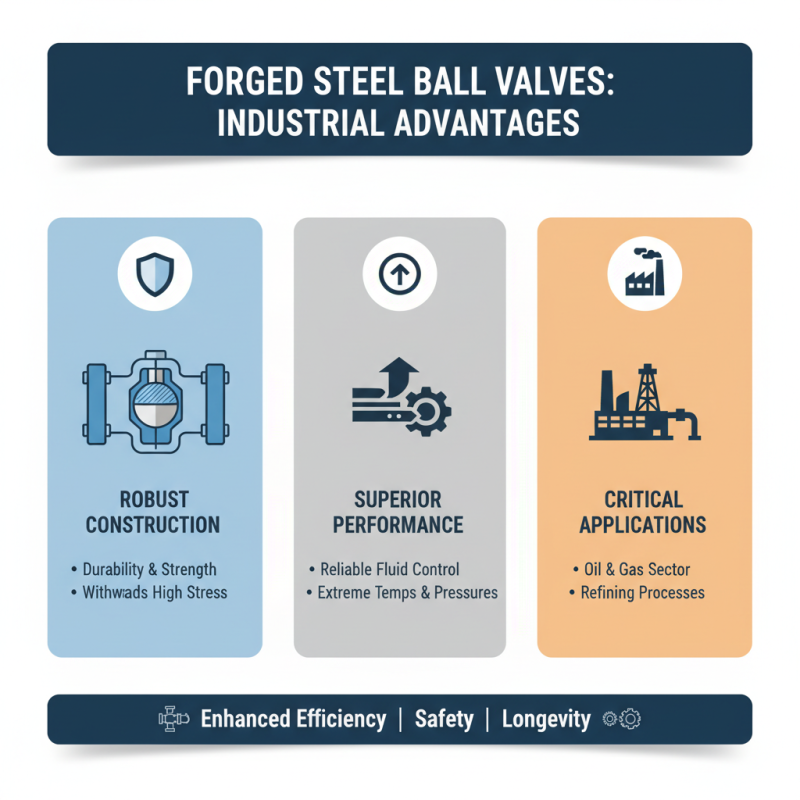

Forged steel ball valves are increasingly gaining traction in industrial applications due to their numerous advantages. One of the primary benefits is their exceptional strength and durability. Unlike standard cast valves, forged steel ball valves undergo a manufacturing process that imparts greater toughness and resistance to high pressures and temperatures. This makes them ideal for demanding environments often encountered in oil and gas, chemical processing, and power generation industries.

Another advantage of forged steel ball valves is their tight sealing capability, which enhances operational efficiency and safety. The design facilitates a nearly leak-proof closure, ensuring that the flow remains contained within the system. This not only reduces the risk of spillage and associated environmental hazards but also minimizes downtime due to maintenance. Additionally, their compact design and lightweight construction allow for easier installation and facilitate better performance in space-restricted settings, further contributing to their popularity in various industrial applications.

When evaluating the best valve types for industrial applications, a comparative analysis between forged steel ball valves and other common valve types, such as gate and globe valves, reveals several compelling advantages. According to a report by Grand View Research, the global industrial valve market was valued at approximately $75 billion in 2020, with forged steel valves taking a significant share due to their superior strength and durability. Forged steel ball valves are known for their ability to withstand high pressures and temperatures, making them ideal for critical applications in oil and gas, chemical processing, and water treatment sectors. Their robust construction results in fewer leak points compared to gate and globe valves, which can be more prone to wear and fatigue over time.

Moreover, the efficiency of forged steel ball valves in terms of flow characteristics cannot be overlooked. With a streamlined design that minimizes pressure drop, these valves can enhance operational efficiency, as outlined in a study published in the Journal of Industrial Valve Technology. The report indicates that ball valves maintain a higher flowrate than globe valves, which often have a significant pressure loss due to their internal design. Additionally, forged steel ball valves generally require less maintenance and offer faster operation due to their quarter-turn functionality, further solidifying their position as a preferred choice in modern industrial settings. As such, the selection of forged steel ball valves over other types within the industrial sector is backed not only by their physical properties but also by their performance metrics that contribute to overall operational efficiency and reliability.

Forged steel ball valves are an ideal choice for various industrial applications due to their exceptional attributes that ensure optimal performance. One of the key features of these valves is their robust construction, which offers superior strength and durability. Forged steel is known for its ability to withstand high pressures and extreme temperatures, making it suitable for demanding environments. Additionally, the tight sealing capability of forged steel ball valves minimizes the risk of leaks, ensuring reliable operation even in critical systems.

Another notable feature of forged steel ball valves is their excellent flow characteristics. The streamlined design of the ball and the valve body facilitates smooth flow with minimal resistance, which reduces energy consumption and enhances overall efficiency. Additionally, these valves provide quick and precise operation, as they can be fully opened or closed with just a quarter turn. This ease of use is significant in applications that require fast shutoff or control, further underscoring the advantages of using forged steel ball valves in industrial settings.

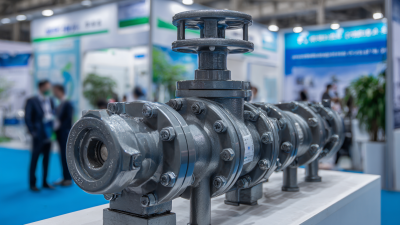

Forged steel ball valves are increasingly popular in a range of industrial applications due to their robust construction and superior performance. In the oil and gas sector, these valves are crucial for controlling fluid flow under high-pressure conditions, providing reliability in critical operations. Their ability to withstand extreme temperatures and pressures makes them ideal for refining processes, where efficiency and safety are paramount.

In power generation, forged steel ball valves are employed to manage steam and water flow in turbines and boilers, ensuring optimal operation of the system. The chemical industry also benefits from these valves, as they resist corrosion and wear, providing longevity in handling corrosive substances. Additionally, forged steel ball valves are utilized in water treatment facilities to regulate flow and pressure while minimizing leaks and maintenance costs.

**Tips:** When selecting forged steel ball valves, consider the specific material grades and pressure ratings to ensure compatibility with your application. Regular maintenance checks can also extend the lifespan of these valves, enhancing their reliability over time. Always consult with an expert to determine the most suitable type of valve for your industrial needs.

Forged steel ball valves are a popular choice in industrial applications due to their superior strength, durability, and resistance to harsh environments. However, to maximize their lifespan and efficiency, regular maintenance is essential. According to industry research, proper maintenance can increase the operational lifespan of ball valves by up to 50%, thereby reducing replacement costs and downtime. Simple actions, such as regular inspections for leaks and wear, can preemptively identify problems that might lead to valve failure.

One of the key maintenance tips is to ensure proper lubrication of the valve components. Using the correct type and amount of lubricant can significantly reduce friction and wear, as noted in a 2021 report by the Industrial Valve Institute, which highlighted that inadequate lubrication is a common cause of premature valve failure. Additionally, keeping the valve clean and free from debris will prevent abrasive particles from causing wear on the sealing surfaces, which can compromise the valve's performance. Regularly checking for and addressing corrosion is also critical, as it can severely affect the integrity of forged steel materials under certain conditions. By adhering to these maintenance practices, industrial operators can ensure that their forged steel ball valves function optimally for years to come.