-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

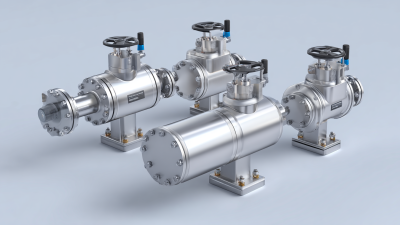

In the realm of industrial applications, the choice of flow control equipment is crucial for ensuring optimal efficiency and operational success. Among these tools, the Three Piece Ball Valve stands out for its versatility and reliability in managing complex fluid dynamics. According to a report by MarketsandMarkets, the global ball valve market is projected to reach $9.2 billion by 2025, with a compound annual growth rate (CAGR) of 5.5%. The prominence of Three Piece Ball Valves can be attributed to their ability to be easily disassembled for maintenance, superior sealing capabilities, and enhanced flow capacity, making them ideal for high-pressure and high-temperature environments. Selecting the right type of Three Piece Ball Valve not only contributes to system efficiency but also plays a significant role in reducing operational costs and downtime, thereby enhancing productivity across various industrial sectors.

In industrial settings, three piece ball valves play a crucial role in controlling fluid flow. These valves are designed with three separate components: the ball, the seat, and the valve body, which allows for easy maintenance and replacement. Understanding the construction and function of these components is essential for selecting the appropriate valve for specific applications. The robust design ensures that they can handle high pressures and temperatures, making them ideal for various industries, including oil and gas, chemical manufacturing, and water treatment.

The operation of a three piece ball valve is straightforward. When the valve handle is turned, the spherical ball inside the valve rotates to either allow or block flow through the pipeline. This design offers minimal resistance to flow when fully opened, which is critical for optimizing flow efficiency. Additionally, the three-piece configuration enables users to disassemble and reassemble the valve without having to remove it from the pipeline, ensuring quick servicing and reduced downtime. With their reliability and efficiency, three piece ball valves are a preferred choice for many industrial applications.

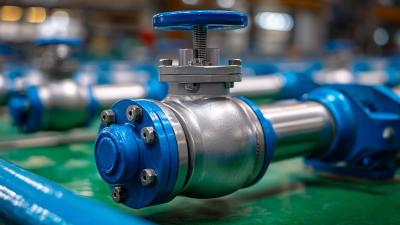

When selecting a three-piece ball valve for industrial applications, several key factors influence flow efficiency. Firstly, the valve size is crucial; it must match the pipe diameter to minimize flow resistance. A valve that is too small can cause significant pressure drops, while an oversized valve may result in turbulent flow, reducing overall efficiency. It’s essential to consider both the nominal flow rate and the specific application requirements to ensure the valve facilitates smooth flow.

Material selection is another critical factor affecting flow efficiency. The valve material should be compatible with the fluid being transported, as corrosion or degradation can lead to leaks and inefficiencies. Additionally, the internal surface finish of the valve plays a role in minimizing friction; smoother surfaces enhance flow rates by reducing turbulence within the valve. Lastly, the design of the valve itself, including features like full bore or reduced bore configurations, significantly impacts flow characteristics and should be matched to the needs of the system for optimal performance.

When selecting a three-piece ball valve for industrial applications, materials and designs play a critical role in ensuring optimal flow efficiency. According to a report by the American Society of Mechanical Engineers (ASME), the right valve material can enhance durability and resistance to corrosion, significantly affecting the valve's operational lifetime. For instance, stainless steel valves are often preferred in chemical processing due to their ability to withstand highly corrosive environments, contributing to a 20-30% increase in service lifespan compared to traditional brass valves.

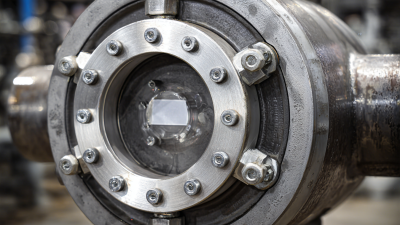

In terms of design, the flow characteristics of the valve significantly impact efficiency. A study published in the Journal of Fluid Mechanics states that the geometry of the ball and the valve seats can influence the turbulence and flow resistance. Utilizing a full-port design, which allows for a smooth, unrestricted flow path, can reduce pressure drops by up to 30%. Furthermore, incorporating features such as blow-out proof stems and multi-way configurations enhances both safety and flexibility, making them suitable for various industrial applications. Thus, the combination of material selection and valve design is pivotal in achieving optimal performance in diverse operational settings.

When selecting a three-piece ball valve for industrial applications, assessing flow capacity and pressure ratings is crucial for ensuring optimal performance. According to the Hydraulic Institute’s "2002 Pumping Systems Optimization" report, a significant proportion of efficiency losses in fluid systems stem from improper valve selection, with some estimates suggesting losses could exceed 30% in poorly matched systems. This underscores the importance of accurately determining the flow requirements and pressure ratings specific to the application at hand.

The flow capacity, often measured in Cv (flow coefficient), is a key factor in valve selection. A study published in the Journal of Pressure Vessel Technology indicates that a valve with a higher Cv value allows for greater flow efficiency, which is essential in maintaining desired production rates. Additionally, understanding the pressure ratings—typically outlined in industry standards such as API 598—ensures that the valve can withstand the operational pressures of the system without risk of failure. For instance, a valve rated for ANSI Class 150 can handle pressures up to 285 psi, making it suitable for many industrial processes that encounter moderate pressure conditions. Thus, thorough evaluation of these metrics aids in selecting the right three-piece ball valve, enhancing overall system efficiency.

When selecting a three-piece ball valve for industrial applications, it’s essential to consider not only the flow efficiency but also the maintenance and troubleshooting aspects that ensure long-lasting performance. Regular upkeep of these valves can significantly affect their operational lifespan and reliability.

To maintain optimal function, it is crucial to conduct routine inspections for signs of wear, leakage, or corrosion. Keeping the valve clean and ensuring that the seals are in good condition can prevent malfunctions. Additionally, operators should be familiar with the valve's specific design and materials to employ appropriate lubricants and cleaning agents.

If issues arise, troubleshooting can often start with checking the valve’s actuation mechanisms. Common problems such as valve sticking or failure to close completely can typically be resolved by identifying debris in the seating area or issues within the actuator. For instance, if a valve is experiencing a leakage, examining the seals and tightening any loose connections can lead to immediate repairs, saving both time and resources in the long run.