-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

Choosing the right Soft Seat Ball Valve for your application is a critical decision that can significantly impact the efficiency and safety of your fluid handling systems. Soft Seat Ball Valves are widely utilized in various industries due to their reliability, ease of use, and ability to create a tight seal, preventing leaks and ensuring smooth operation. However, with a myriad of options available on the market, selecting the most suitable valve requires a comprehensive understanding of the specific requirements of your application.

When considering a Soft Seat Ball Valve, it is essential to evaluate factors such as the type of fluid being controlled, the pressure and temperature conditions, and the overall system design. Each application may demand different features, such as resistance to corrosion, the size of the valve, and the connection type. Additionally, understanding the operational environment, including potential exposure to harmful substances or extreme conditions, will guide you in making a more informed choice.

By carefully analyzing these factors and aligning them with the characteristics of Soft Seat Ball Valves, you can optimize your selection process. This will not only enhance system reliability but also contribute to long-term cost savings and improved safety standards in your operations.

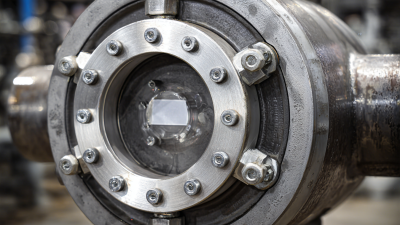

Soft seat ball valves are widely recognized for their unique design, which provides enhanced sealing capabilities and operational efficiency. These valves feature a flexible sealing element, usually made of materials like rubber or plastic, that conforms to the ball surface. This ensures a tight seal across a wide range of pressures and temperatures, making them suitable for various applications, from water and wastewater systems to chemical processing. The soft seat allows for low torque operation, meaning they require less effort to open and close, which can save on wear and tear over time.

In addition to their sealing advantages, soft seat ball valves are known for their durability and versatility. They can handle different media types, including gases, liquids, and slurries, depending on the material used for the soft seat. This adaptability makes them an ideal choice for many industrial applications, where conditions can change frequently. Furthermore, their design minimizes leakage risks, contributing to safer operation and compliance with environmental standards. By understanding the benefits of soft seat ball valves, users can make informed decisions that enhance performance and reliability in their specific applications.

| Dimension | Value | Description |

|---|---|---|

| Material | PVC/CPVC/SS | Types of materials used for construction |

| Size | 1/2" to 12" | Available sizes for various applications |

| Pressure Rating | 150 psi to 600 psi | Maximum allowable pressure for reliable operation |

| Temperature Range | -20°F to 300°F | Operational temperature limits |

| End Connections | Threaded, Flanged, Welded | Types of connections available for installation |

| Applications | Water, Chemicals, Gas | Common uses for soft seat ball valves |

| Benefits | Low Torque, Bubble-tight Seal | Advantages of soft seat ball valves |

When selecting the appropriate soft seat ball valve for a specific application, it is crucial to first identify key application requirements. Understanding the fluid characteristics, including viscosity, temperature, and the chemical composition, plays a pivotal role in ensuring optimal valve performance. For instance, a study from the Flow Control Magazine indicated that fluid viscosity can significantly impact the valve's flow rate, with higher viscosities necessitating valves designed for higher torque and sealing capabilities. This ensures that the valve operates efficiently without leakage or excessive wear.

In addition to fluid characteristics, operating conditions such as pressure and flow rate are essential factors that must be considered. According to a report by the Valve Manufacturers Association, nearly 30% of valve failures can be attributed to selecting valves that do not meet the pressure and flow requirements of the system. It is also advisable to examine the potential for abrasive or corrosive substances within the medium, as these can affect the valve's longevity and functionality. When engineers incorporate these parameters into their selection process, they are better positioned to choose a soft seat ball valve that not only meets current operational needs but also provides cost-effective maintenance and increased system reliability.

When selecting a soft seat ball valve, one of the most critical factors to consider is the material of the soft seat itself. The soft seat is crucial for ensuring a tight seal and preventing leaks, which is why understanding the properties of different materials can greatly influence the performance and longevity of the valve in various applications. Common materials used for soft seats include elastomers such as EPDM, nitrile, and PTFE. Each material has unique characteristics that make it suitable for specific operating conditions, such as temperature ranges, chemical compatibility, and pressure requirements.

For instance, EPDM is well-regarded for its excellent resistance to heat and weathering, making it an ideal choice for outdoor applications or environments that experience significant temperature fluctuations. On the other hand, nitrile offers superior resistance to oils and fuels, which is advantageous in petroleum-related applications. PTFE, known for its non-stick properties and outstanding chemical resistance, is frequently used in aggressive chemical environments. By carefully evaluating the application requirements and the strengths of each material, users can make informed choices that enhance valve performance and reliability.

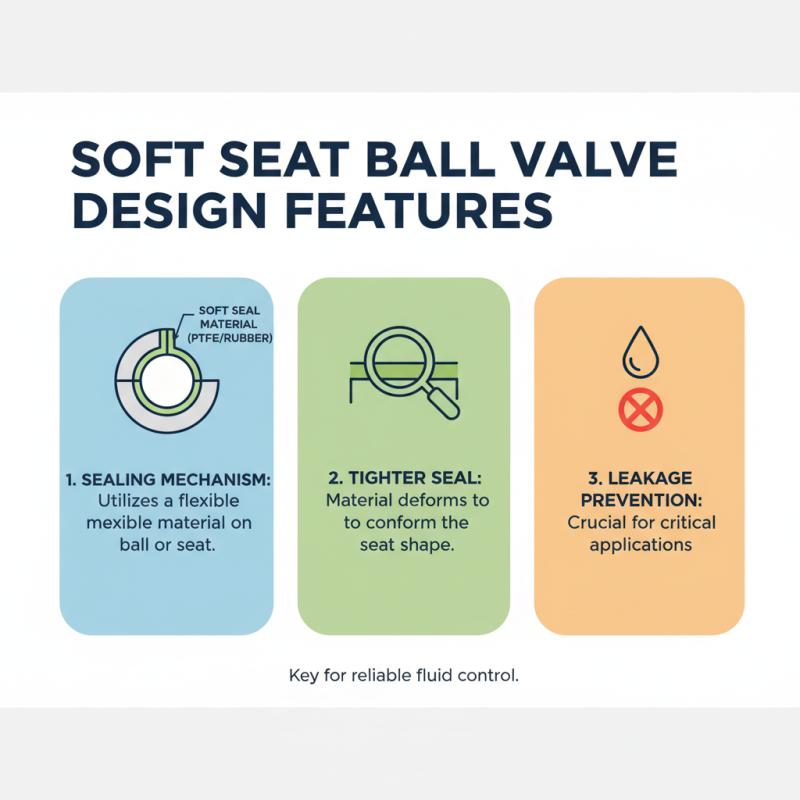

When selecting the right soft seat ball valve for your application, understanding the design features specific to these valves is crucial. Soft seat ball valves are distinguished by their sealing mechanism, which typically utilizes a soft material like PTFE or rubber on the ball or seat. This design enables a tighter seal, which is particularly advantageous in applications where leakage prevention is paramount. The flexibility of the soft material allows it to deform slightly, thus conforming to the shape of the seat and enhancing the valve's sealing capability.

Another important aspect to consider is the construction materials used in soft seat ball valves. The choice of materials impacts not only the valve's performance but also its compatibility with various fluids and environments. For instance, valves designed for high-temperature or corrosive applications may incorporate specialized soft seat materials or coatings that can withstand such conditions. Additionally, the valve body design, whether a split body or a one-piece construction, influences the ease of maintenance, repairability, and overall durability, making it a key factor in decision-making for specific applications.

Ultimately, a thorough assessment of these design features can guide you in choosing the most suitable soft seat ball valve for your needs, ensuring optimal performance and longevity in your system.

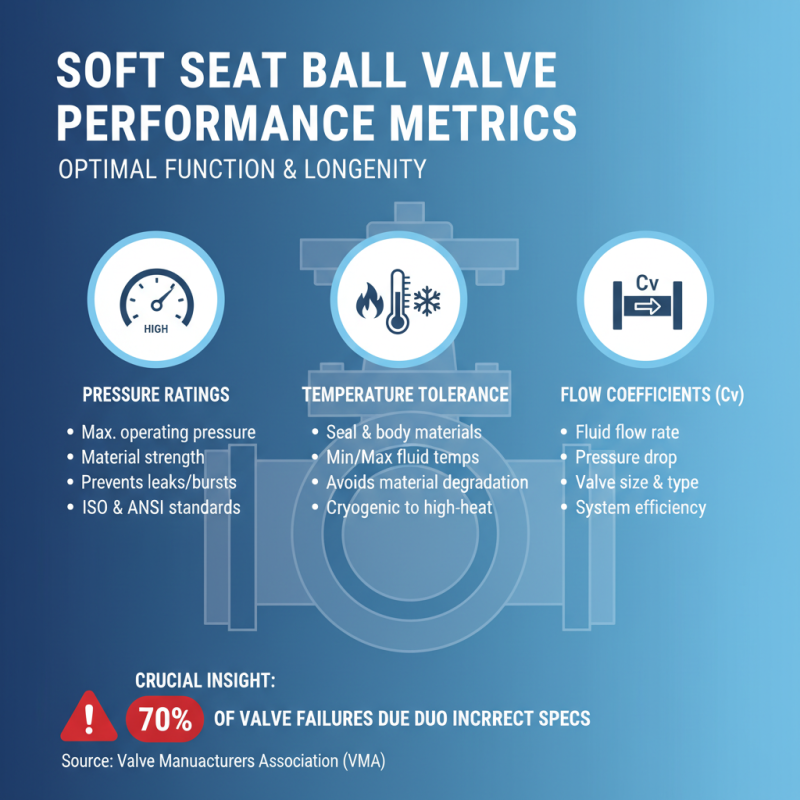

When selecting a soft seat ball valve for a specific application, understanding performance metrics is crucial to ensure optimal functionality and longevity. Key factors include pressure ratings, temperature tolerance, and flow coefficients. According to the Valve Manufacturers Association (VMA), nearly 70% of valve failures can be traced back to incorrect specifications for pressure and temperature, highlighting the importance of accurate application analysis.

In addition to pressure and temperature, the material compatibility must also be assessed. For instance, certain soft seat materials like PTFE exhibit excellent chemical resistance, making them suitable for aggressive fluids. The American Society of Mechanical Engineers (ASME) reports that using the correct material can increase the lifespan of a valve by up to 30%. Furthermore, flow coefficients (Cv values) play a significant role in determining the efficiency of a valve in regulating flow. Valves with higher Cv values can handle larger volumes of fluid, which is essential in high-demand situations. Thus, a thorough evaluation of these performance metrics will significantly impact the reliability and efficiency of soft seat ball valves in various applications.