-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

When it comes to plumbing, one of the critical components that often goes unnoticed is the ball valve. These simple yet essential devices control the flow of water and ensure that your plumbing system operates efficiently. According to John Smith, a renowned plumbing expert with over 20 years of experience in the industry, “Selecting the right ball valves is vital for ensuring both the longevity of your system and the safety of your home.”

Choosing the right ball valves involves understanding various factors, including the type of materials used, the operating pressure, and the intended application. Whether for residential or commercial purposes, the decision-making process can significantly impact the overall performance of your plumbing setup. As plumbing systems become more complex, the role of ball valves becomes increasingly important, making it essential for homeowners and professionals alike to make informed choices.

In this guide, we will explore the key considerations for selecting the right ball valves. By examining the critical aspects of these valves, you can ensure that your plumbing system remains in top condition, providing reliable and efficient service for years to come.

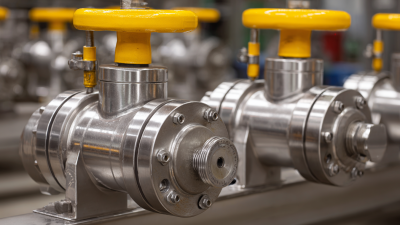

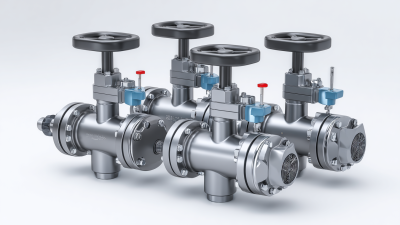

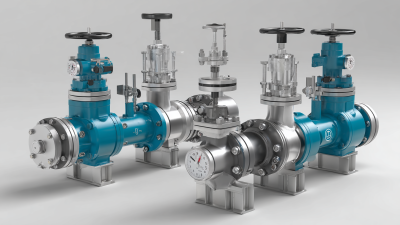

When selecting the right ball valves for your plumbing needs, understanding the different types available is crucial. Ball valves are typically categorized based on their construction and function. The most common types include full port, reduced port, and V-port ball valves. Full port ball valves have a wider opening that allows for maximum flow, making them ideal for applications that require high capacity. In contrast, reduced port ball valves have a smaller opening which can lead to pressure drops, but are often more cost-effective and suitable for applications where flow is less of a concern.

Another significant classification involves the material used in the ball valve construction. Common materials include brass, stainless steel, and PVC, each offering distinct advantages. Brass valves are durable and resistant to corrosion, making them suitable for both hot and cold water applications. Stainless steel valves provide even greater durability and are often used in more demanding environments, such as those involving chemicals or high pressures. PVC ball valves, on the other hand, are lightweight and corrosion-resistant, making them ideal for applications involving certain liquids or environments. By understanding these various types and materials, you can make an informed decision that best suits your specific plumbing needs.

| Type of Ball Valve | Materials | Pressure Rating | Temperature Range | Common Applications |

|---|---|---|---|---|

| Full Port Ball Valve | Brass, Stainless Steel, PVC | up to 600 psi | -20°F to 350°F | Water, Gas, Oil |

| Reduced Port Ball Valve | Brass, Stainless Steel | up to 400 psi | -20°F to 250°F | Hydraulic Systems, Water Supply |

| Trunnion Ball Valve | Stainless Steel, Carbon Steel | up to 1000 psi | -40°F to 400°F | Marine, Oil, and Gas |

| Electric Ball Valve | PVC, Stainless Steel | up to 150 psi | -4°F to 176°F | Irrigation, HVAC Systems |

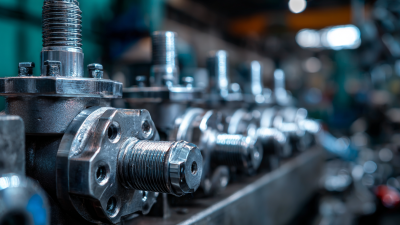

When selecting the right ball valves for plumbing systems, proper sizing is crucial for ensuring optimal flow performance and system efficiency. According to industry reports, an oversized valve can lead to inefficient flow control, causing turbulence and pressure drops, while an undersized valve may restrict flow and lead to potential system failures. It's essential to calculate the correct flow requirements based on the specific application to avoid these pitfalls.

One key aspect in sizing ball valves is understanding the flow coefficient (Cv) value, which indicates the valve's capacity to allow fluid flow. A report by the American Society of Plumbing Engineers suggests that a valve’s Cv must align with the system's flow demands to maintain the desired pressure drop. For instance, the Cv needed for a particular system can be determined by analyzing the flow rate and the type of fluid being carried. By meticulously evaluating these parameters, plumbers can select ball valves that maximize efficiency and longevity in plumbing systems. Balancing these considerations can lead to significant savings on operational costs and maintenance in the long run.

When selecting the right ball valve for plumbing applications, material selection plays a crucial role in ensuring durability, performance, and compatibility with the intended medium. Common materials for ball valves include brass, stainless steel, and PVC, each offering distinct advantages depending on the application. According to a report by the American Society of Plumbing Engineers, approximately 60% of plumbing failures can be attributed to material incompatibility, underlining the importance of choosing the correct material for specific environments.

For corrosive environments, stainless steel is often recommended due to its resistance to rust and oxidation, making it ideal for applications involving water treatment or chemical processing. Conversely, PVC valves are typically preferred in non-corrosive situations, particularly for residential plumbing, owing to their lightweight nature and cost-effectiveness. According to industry data, using the appropriate valve material can extend service life by up to 20%, significantly reducing long-term maintenance costs.

Furthermore, temperature and pressure ratings should guide material choices; for instance, high-temperature applications demand materials like brass or stainless steel, capable of maintaining structural integrity under such conditions. The International Plumbing Code emphasizes that improper material selection can lead to increased failure rates and safety hazards, further stressing the importance of careful assessment. Hence, evaluating the operational environment and specific application needs is essential for selecting the right ball valve material, ultimately contributing to a reliable plumbing system.

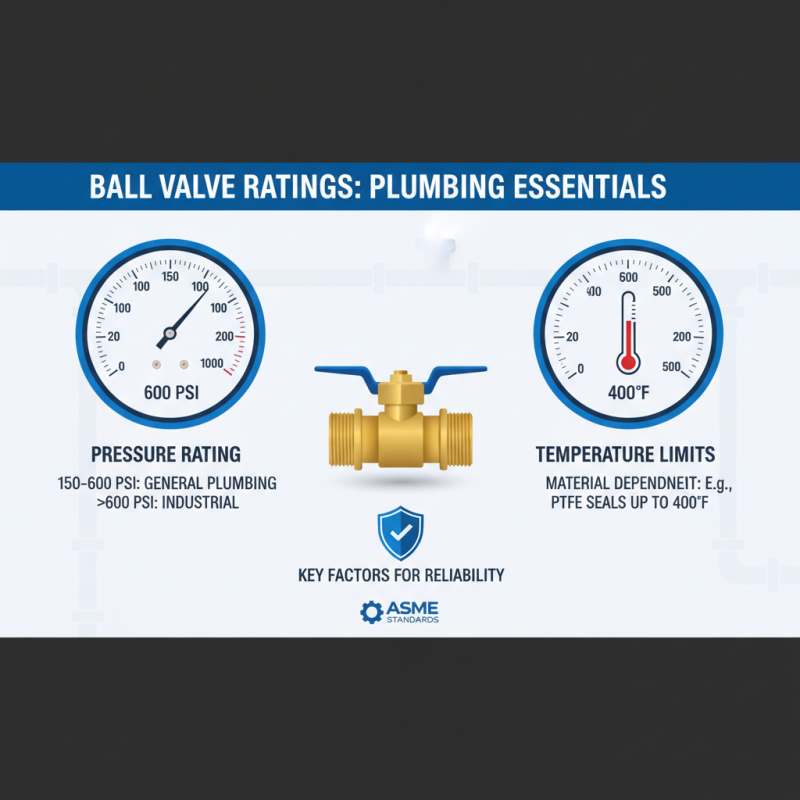

When selecting ball valves for plumbing applications, it's crucial to evaluate their pressure ratings and temperature limits, as these factors significantly impact performance and reliability. According to a report by the American Society of Mechanical Engineers (ASME), the pressure rating of a valve determines its ability to withstand internal pressures without leaking or failing. Typically, ball valves are available with pressure ratings ranging from 150 psi to 600 psi for general applications. High-pressure environments, such as industrial settings, may require valves with ratings exceeding 600 psi, making it essential to choose a valve that aligns with the specific demands of your system.

Temperature limits are equally important, as operating conditions can vary widely. A study published in the Journal of Pressure Vessel Technology indicates that standard ball valves can often handle temperatures from -20°F to 300°F, with some high-performance models designed to operate at temperatures as high as 500°F. When selecting a ball valve, it is essential to assess the maximum and minimum temperature conditions of your plumbing system. Using a valve beyond its specified temperature limit can lead to material degradation, seal failure, and ultimately, system leaks. Therefore, ensuring that the ball valves you choose are rated for the specific pressure and temperature conditions of your application is vital for long-term operational efficiency.

When it comes to ball valves, proper installation and maintenance are critical to ensuring optimal performance in your plumbing systems. According to industry reports, approximately 20% of plumbing issues can be traced back to improper valve installation or neglecting maintenance protocols.

First and foremost, it is essential to select the appropriate size and type of ball valve based on your system's requirements. Installation should be executed with precision, ensuring that the valve is oriented correctly in the pipeline, typically with the handle in line with the flow of water. Utilizing Teflon tape on threads can help prevent leaks, while a proper torque setting during installation can minimize the risk of valve damage.

Maintenance is equally vital. Regular inspections should be conducted to check for signs of wear, corrosion, or leakage. The American Society of Plumbing Engineers recommends exercising the valve at least twice a year to prevent the ball from seizing in place. This exercise ensures that the valve seals remain intact and functional, extending the valve's lifespan.

Moreover, incorporating a routine inspection schedule can help mitigate potential problems before they escalate. Engaging in proactive maintenance can lead to a reduction in repairs by up to 30%, thus providing significant cost savings and improved efficiency in plumbing operations.