-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In today's industrial landscape, the selection of the right fittings and valves is crucial for ensuring optimal performance and safety in fluid control applications. The Casting Ball Valve has emerged as a preferred choice across various sectors due to its durability, reliability, and superior sealing capabilities. According to a report by MarketsandMarkets, the global ball valve market is expected to grow from USD 9.4 billion in 2020 to USD 12.2 billion by 2026, reflecting a CAGR of 4.7%. This growth underscores the increasing demand for advanced valve technologies in industries like oil and gas, water treatment, and chemical processing. However, with numerous options available, selecting the best Casting Ball Valve tailored to your specific operational requirements can be a daunting task. This ultimate guide aims to equip you with the necessary insights and considerations, enabling you to make informed decisions that meet your industry's unique challenges.

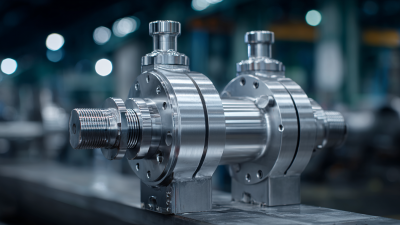

When selecting a casting ball valve for your industry, it’s essential to understand the various types available to ensure optimal performance and compatibility with your specific applications. The most common types include floating ball valves, trunnion-mounted ball valves, and full-port ball valves, each serving unique purposes based on pressure, flow requirements, and space constraints. Floating ball valves are often used in low-pressure applications and rely on the media pressure to seal the ball against the seat, making them suitable for smaller pipelines.

On the other hand, trunnion-mounted ball valves are designed for high-pressure applications and feature a fixed ball that is supported by trunnions, providing stability and reducing wear over time. This design is particularly advantageous in critical systems where flow rates must remain consistent and safe. Meanwhile, full-port ball valves allow for unrestricted flow and are ideal for applications where minimal pressure drop and full flow capacity are requirements. Understanding these differences can help industries select the right valve type that meets their specific operational needs and enhances system efficiency.

| Valve Type | Material | Pressure Rating | Size Range | Applications |

|---|---|---|---|---|

| Full Port | Cast Iron | 150 PSI | 1" to 12" | Water Supply, HVAC |

| Reduced Port | Stainless Steel | 300 PSI | 1" to 6" | Chemical Processing |

| Floating Ball | Brass | 200 PSI | ½" to 4" | Oil and Gas |

| Trunnion Ball | Carbon Steel | 600 PSI | 2" to 24" | High Pressure Systems |

| Electric Actuated | PVC | 150 PSI | 1" to 8" | Plastic Industry |

When selecting a casting ball valve for your industry needs, it is crucial to consider several key factors that can greatly impact performance and longevity. First and foremost, the material of the valve is a significant consideration. Depending on the nature of the fluids being handled—whether corrosive, high-temperature, or high-pressure—choosing the right material, such as stainless steel, bronze, or ductile iron, ensures optimal compatibility and durability. A well-suited material can prevent leaks and prolong the lifespan of the valve.

Another important aspect to evaluate is the valve's size and connection type. Proper sizing ensures that the flow rate meets operational requirements while maintaining pressure integrity. Additionally, the compatibility of connection types (like flanged, threaded, or welded) with existing systems is vital to avoid installation challenges. Lastly, the valve's design, including features like a full port or reduced port option, can directly influence flow efficiency and operational ease. By carefully analyzing these factors, industries can select the most appropriate casting ball valve to meet their specific needs and enhance their system's effectiveness.

When selecting the best casting ball valve for your industry needs, the material type plays a crucial role in ensuring durability and efficiency. Common materials used in casting ball valves include stainless steel, brass, and carbon steel, each offering distinct advantages. Stainless steel valves are often favored for their corrosion resistance and ability to withstand high temperatures, making them ideal for applications in the chemical and pharmaceutical industries. On the other hand, brass valves provide excellent resistance to rust and are often more cost-effective, suitable for residential plumbing installations.

Meanwhile, carbon steel valves offer strength and durability, particularly in high-pressure applications, though they may require additional coatings to resist corrosion in harsh environments. It’s essential to consider the operating conditions, such as fluid type, temperature, and pressure, when choosing the right material. For industries exposed to aggressive chemicals, a high-performance plastic valve may also be a viable alternative, providing excellent resistance without the heavy weight of metal options. Ultimately, understanding the specific material characteristics will help you make an informed decision that enhances the longevity and reliability of your casting ball valves.

This chart compares the durability and suitability of various materials used in casting ball valves for different industry needs.

When selecting the best casting ball valve for your industry needs, understanding the temperature and pressure ratings is crucial. These parameters directly influence the valve's performance and longevity in specific applications. For example, according to a report by the Valve Manufacturers Association, properly rated valves can reduce failure rates by up to 40% in high-pressure environments. Valves designed for extreme conditions should generally have a pressure rating that exceeds the maximum pressure of the system by at least 25%.

Tips: Always check the temperature ratings against your operational parameters, as exceeding these limits can lead to catastrophic failures. A valve with a temperature rating lower than your process requirements might fail prematurely, leading to costly downtime and repairs.

In industries such as oil and gas, where pressure fluctuations can be significant, the American Society of Mechanical Engineers (ASME) recommends using valves that comply with their pressure rating standards, ensuring safety and reliability under varying conditions. Choosing a valve that meets or exceeds these ratings not only enhances operational efficiency but also ensures compliance with regulatory standards, thus safeguarding your operations against potential hazards.

Tips: Consider consulting with a valve specialist to verify that the chosen model meets your industry's specific pressure and temperature requirements. Regular audits of your installed valves can also prevent unexpected failures and maintenance costs.

Casting ball valves play a pivotal role in a wide range of industries, thanks to their durability and efficient flow control. In the oil and gas sector, for instance, these valves are essential for maintaining high-pressure environments. According to a report by MarketsandMarkets, the global ball valve market is expected to reach USD 8.74 billion by 2027, growing at a CAGR of 5.8%. This growth highlights the rising demand for reliable flow control solutions in energy production, particularly in the exploration and transportation of oil and gas.

Casting ball valves play a pivotal role in a wide range of industries, thanks to their durability and efficient flow control. In the oil and gas sector, for instance, these valves are essential for maintaining high-pressure environments. According to a report by MarketsandMarkets, the global ball valve market is expected to reach USD 8.74 billion by 2027, growing at a CAGR of 5.8%. This growth highlights the rising demand for reliable flow control solutions in energy production, particularly in the exploration and transportation of oil and gas.

In the water and wastewater treatment industry, casting ball valves are crucial for regulating the flow of liquids and ensuring system integrity. The American Water Works Association (AWWA) has shown that improper valve selection can lead to significant operational inefficiencies, costing companies thousands in maintenance and operational expenses. A well-chosen casting ball valve can provide greater resistance to corrosion and wear, enhancing system performance and reducing downtime. As water scarcity becomes an increasing concern worldwide, efficient water management solutions are more critical than ever, further boosting the demand for high-quality casting ball valves across various applications.