-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

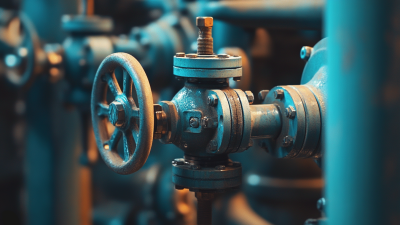

When selecting a Pneumatic Operated Ball Valve for your application, it is essential to consider a range of factors that can significantly impact the performance and reliability of your system. Pneumatic Operated Ball Valves are crucial components in various industries, offering efficient flow control, quick actuation, and enhanced operational safety.

However, with the multitude of options available on the market, choosing the right one can be a daunting task. This guide aims to simplify the decision-making process by outlining key considerations such as valve size, material compatibility, pressure ratings, and actuation methods. By understanding these factors, you can ensure the Pneumatic Operated Ball Valve you select aligns perfectly with your specific requirements, ultimately optimizing your system's functionality and efficiency.

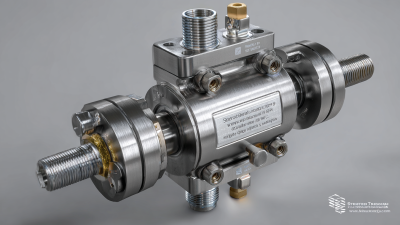

Pneumatic operated ball valves are essential components in various industrial applications due to their efficient performance and reliability. These valves utilize compressed air to operate the valve mechanism, allowing for quick and precise control of fluid flow.

According to a report by Markets and Markets, the global pneumatic valve market is expected to grow from USD 4.2 billion in 2021 to USD 5.5 billion by 2026, highlighting the increasing demand for pneumatic systems across different sectors, including oil and gas, water and wastewater management, and pharmaceuticals.

Understanding the basics of pneumatic operated ball valves involves familiarizing oneself with their construction, operation, and the factors influencing their selection. These valves typically feature a spherical disc, or ball, with a hole through the middle that aligns with the pipeline to allow flow when open.

Key considerations in choosing the right valve for a specific application include the size of the valve, the pressure and temperature specifications, and the type of fluid being transported. A study by Frost & Sullivan emphasized that selecting the appropriate valve can improve system efficiency by up to 20%, underscoring the importance of informed decision-making in valve operations.

When selecting a pneumatic operated ball valve, it is crucial to first identify the specific needs and requirements of your application. Consider the type of fluid being transported, as this will influence the choice of material for the valve. For instance, corrosive chemicals may require stainless steel components, while water applications might allow for more economical materials. Additionally, evaluate the operating temperature and pressure conditions, as these factors determine the valve's performance and longevity.

Another important aspect is the control mechanism. Depending on your system's demands, you may need a valve that can offer precise flow control or rapid on/off capabilities. Assess whether automatic control is necessary, which would require additional components such as sensors and controllers. Lastly, consider the size of the valve in relation to your piping system to ensure adequate flow rates without compromising efficiency. By thoroughly understanding these factors, you can make an informed decision that enhances your operation's overall effectiveness.

| Application Type | Pressure Rating (psi) | Temperature Range (°F) | Material | End Connection Type |

|---|---|---|---|---|

| Water Treatment | 150 | 32 - 140 | PVC | Socket Weld |

| Chemical Processing | 300 | 40 - 180 | 316 Stainless Steel | Flanged |

| Oil & Gas | 600 | -20 - 300 | Carbon Steel | Buttweld |

| Food & Beverage | 150 | 35 - 180 | 304 Stainless Steel | Tri-Clamp |

| HVAC Systems | 200 | 32 - 250 | Brass | NPT |

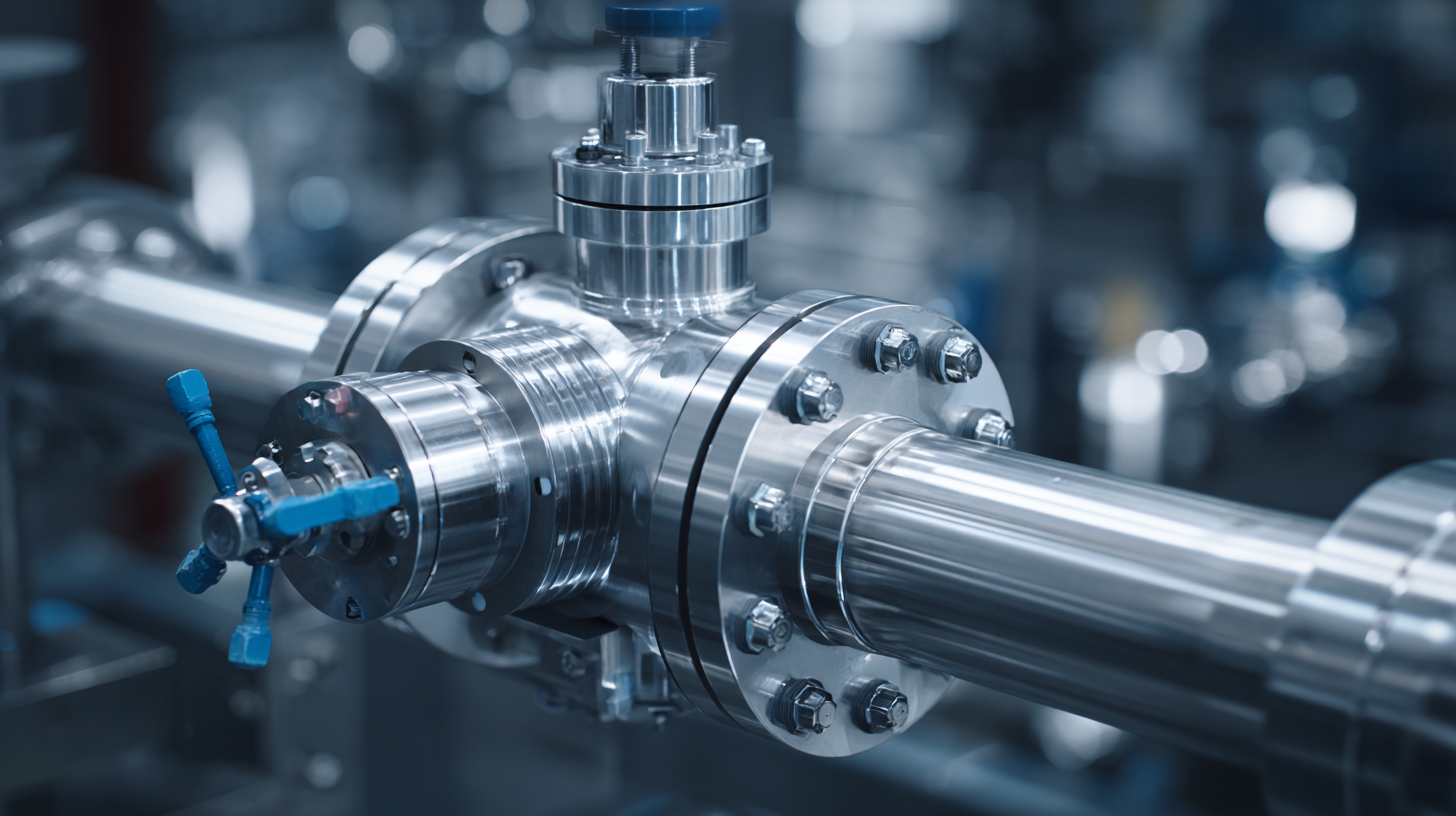

When choosing the right pneumatic operated ball valve for your application, evaluating material compatibility is crucial. Materials must be resistant to the process media they will encounter; otherwise, degradation can occur, leading to failures and costly downtime. According to a report by the Market Research Future, the global industrial valves market is expected to reach USD 92 billion by 2025, showcasing the increasing need for reliability and durability in valve materials. Common materials used for ball valves include stainless steel, brass, and various plastics, each offering distinct advantages depending on the operating environment.

Performance standards are another key component in the selection process. The American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) provide guidelines that ensure valve performance and quality. For instance, ASME B16.34 outlines design, materials, and testing standards that pneumatic valves must meet. Compliance with these standards not only assures safety and performance but also extends the lifespan of the valves, minimizing maintenance costs. Utilizing valves that adhere to these rigorous standards can significantly enhance system performance and reliability in industrial applications.

When selecting a pneumatic operated ball valve for your application, it's crucial to focus on the size and flow capacity to ensure optimal performance. According to the latest flow analysis reports from industry experts, proper sizing can significantly enhance system efficiency, with poorly sized valves potentially causing up to 30% energy loss in fluid systems. Understanding your system’s requirements is the first step; this includes considering the maximum flow rate, fluid viscosity, and the pressure conditions under which the valve will operate.

Typically, flow capacity is expressed in terms of Cv (flow coefficient), which quantifies the valve's ability to allow fluid flow. Industry standards suggest that selecting a valve with a Cv that matches or slightly exceeds your system's requirements can mitigate the risk of cavitation and ensure smooth operation. For example, a pneumatic ball valve with a Cv of 10 can handle flows of up to 10 gallons per minute of water at a specific pressure drop. Therefore, by accurately assessing the flow demands of your application, you can select a valve that not only fits the physical dimensions but also optimizes flow efficiency, ultimately reducing operational costs and downtime in your system.

When selecting a pneumatic operated ball valve for your application, it’s crucial to assess the control options and actuation methods available.

These factors significantly influence the efficiency and effectiveness of the system. Different applications may require varying levels of precision, speed, and responsiveness, which are directly impacted by the chosen actuation method, whether it be single-acting or double-acting actuators. Understanding the demands of your process will guide you in making the right selection.

These factors significantly influence the efficiency and effectiveness of the system. Different applications may require varying levels of precision, speed, and responsiveness, which are directly impacted by the chosen actuation method, whether it be single-acting or double-acting actuators. Understanding the demands of your process will guide you in making the right selection.

Tip: Evaluate the specific requirements of your application, including pressure, temperature, and the type of fluid being controlled. This evaluation will help determine the suitability of different actuation methods.

Additionally, consider the control options at your disposal, such as manual, local, or remote controls. Each of these options offers unique advantages depending on your operational needs. For instance, remote control systems facilitate safer operation in hazardous environments, while local controls may enhance accessibility in more modest setups.

Tip: Experiment with varying control interfaces to identify which offers the best operator experience and efficiency for your specific application.