-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the world of industrial applications, the choice of a Double Block Bleed Valve can significantly impact safety and efficiency. These specialized valves play a crucial role in isolating sections of piping systems while allowing for safe maintenance procedures. When considering the right Double Block Bleed Valve for your needs, it is essential to understand the various types and features available in the market. This ultimate checklist will guide you through the critical factors to consider, such as material compatibility, pressure ratings, and operational requirements. By evaluating these elements systematically, you can ensure that the Double Block Bleed Valve you select will not only meet your immediate operational needs but also enhance the longevity and reliability of your piping system. Join us as we delve into the essentials of choosing the best Double Block Bleed Valve tailored to your specific application requirements.

When selecting a double block bleed valve, understanding the common issues associated with these critical components is essential. One prevalent issue is the risk of leakage. Double block bleed valves are designed to ensure integrity in the system by isolating fluid flow. However, if seals degrade over time due to wear or improper installation, they can become a source of leaks, compromising the entire system's safety. Regular maintenance and inspection are crucial to mitigate this risk and ensure that valves function as intended.

Another common problem is the potential for corrosion. Given their frequent exposure to harsh chemicals or extreme environments, double block bleed valves can suffer from corrosion, which affects their longevity and reliability. It’s important to select valves made from appropriate materials that can withstand the specific conditions of your application. Additionally, utilizing protective coatings or selecting valves designed for corrosive environments can help enhance their durability. By being aware of these issues, you can make informed decisions when choosing a double block bleed valve that meets your operational needs.

| Feature | Importance | Common Issues | Recommended Solutions |

|---|---|---|---|

| Material Compatibility | High | Corrosion or wear | Choose suitable materials for media. |

| Temperature Range | Medium | Failure due to extreme heat/cold | Select a valve rated for the specific temperature. |

| Pressure Rating | High | Leakage under high pressure | Ensure pressure rating exceeds maximum operating pressure. |

| Size and Dimensions | Medium | Installation issues | Measure installation space accurately before selection. |

| Actuation Type | Medium | Slow operation | Opt for electric or pneumatic actuation for efficiency. |

| Maintenance Needs | High | Increased downtime | Choose valves with low maintenance requirements. |

When choosing the best double block bleed valve, understanding the right specifications for your application is crucial. Specifications not only determine the operational efficiency of the valve but also ensure that it aligns with industry standards and regulatory requirements. Just as in other fields, such as quality control and material selection, having a clear identification system can streamline the selection process. By thoroughly evaluating the necessary parameters—such as pressure ratings, temperature ranges, and material compatibility—you can avoid unsatisfactory performance and costly errors.

For instance, in the same way that one might identify the characteristics of an HDMI cable or analyze a laptop’s specifications, defining the operational environment and required features of the double block bleed valve should be an organized process. This approach will lead to a much clearer understanding of which valve will meet your needs effectively. As industries continue to evolve, having a detailed understanding of your valve's specifications not only enhances operational reliability but also contributes to overall safety and compliance in your application.

When selecting a double block bleed valve, understanding the maintenance requirements is crucial to avoid operational issues in the long run. Regular inspection and servicing can prevent unexpected failures, which could lead to costly downtime. Always refer to the manufacturer's guidelines for specific maintenance intervals and recommended practices.

Tip: Implement a scheduled maintenance program to routinely check seals and seating surfaces for wear. This proactive approach can catch potential problems early, ensuring that valves operate effectively when needed.

Additionally, keep a close eye on the valve's surrounding environment. Corrosive substances, extreme temperatures, and fluctuating pressures can all affect valve performance.

Tip: Consider using protective coatings or enclosures to shield valves from harsh conditions, as this can extend their lifespan significantly. By prioritizing maintenance and environmental considerations, you can ensure your double block bleed valve consistently meets operational demands.

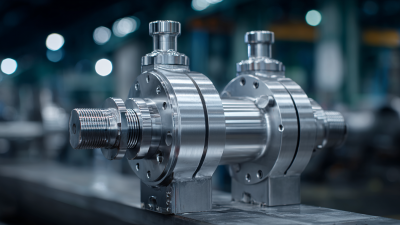

Selecting the right material for a double block bleed valve is crucial as it directly influences the valve's performance and longevity. In recent advancements, studies have emphasized the importance of material selection in the development of various valve types, from automotive engine valves to innovative heart valves. For example, the use of composite materials has demonstrated superior fatigue resistance, which is vital for components subjected to regular mechanical stress. Choosing a material that can withstand not just repeated cycles but also extreme environmental conditions significantly enhances the reliability of the valve.

Furthermore, the introduction of novel polymeric materials in valve design, particularly in medical applications like transcatheter heart valves, showcases how material properties can affect functionality. Computational modeling techniques have informed the design of these valves, ensuring that the material selection aligns with the desired performance outcomes, such as improved blood flow and reduced wear. The trend towards lightweight and durable composite materials in various industries, including automotive and medical, underscores the pivotal role that appropriate material choices play in achieving optimal performance and efficiency in valve technology.

When it comes to double block bleed valves, troubleshooting frequent failures is crucial for maintaining efficiency and safety in fluid systems. Industry reports indicate that improper installation and lack of maintenance are two leading causes of valve failure. In fact, data suggests that nearly 30% of valve-related issues can be traced back to installation errors, underscoring the importance of following manufacturer guidelines and ensuring proper alignment during installation.

Another common source of failure is accumulations of debris and sediment in the valve body, which can lead to blockages and malfunctions. According to studies, regular maintenance checks can reduce the likelihood of these failures by up to 50%. Implementing a routine inspection schedule allows for early detection of potential issues, enabling timely interventions that prevent costly downtime and repairs. Keeping the valve clean and ensuring appropriate bleed procedures are followed can significantly enhance the longevity and reliability of double block bleed valves in various applications.