-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In today's dynamic industrial landscape, the significance of optimally functioning valves cannot be overstated, particularly the Casting Ball Valve. This type of valve is not only renowned for its reliability and performance but also plays a pivotal role in fluid control systems across various sectors, including oil and gas, water treatment, and chemical processing. According to a recent market analysis by Grand View Research, the global ball valve market is projected to reach USD 8.06 billion by 2028, driven by the increasing demand for efficient flow control solutions and innovations in valve technologies.

The essential benefits of Casting Ball Valves, such as reduced flow resistance, minimal pressure drop, and enhanced durability, contribute to their growing adoption. These valves are engineered to withstand extreme conditions, offering exceptional sealing performance and ease of operation. As industries increasingly seek to optimize their processes while maintaining cost-efficiency, the role of high-quality Casting Ball Valves becomes even more critical. Insights from industry reports emphasize the need for advancements in material engineering and design to meet the evolving demands for sustainability and reliability in valve performance.

Ultimately, the integration of Casting Ball Valves into fluid management systems is indicative of broader trends within the industry, such as the shift towards automation and the reliance on technologically advanced solutions. As market dynamics continue to evolve, understanding the performance characteristics and advantages of Casting Ball Valves will be key for stakeholders aiming to enhance operational efficiency and ensure optimal system performance.

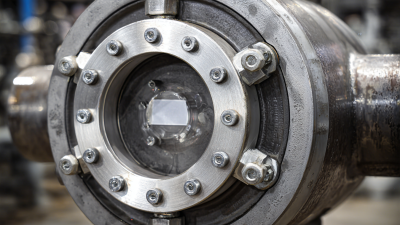

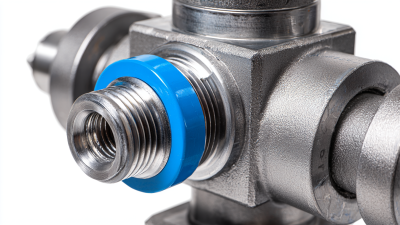

Casting ball valves are critical components widely used in various industrial applications due to their robust structure and reliable functionality. Comprised of a spherical disc or ball that controls the flow of fluid, these valves offer a straightforward yet effective design. The primary feature of casting ball valves is the precisely machined ball that rotates within a seat, either allowing or obstructing flow. This simplistic mechanism provides excellent sealing properties and minimizes the risk of leakage, which is essential for maintaining pressure and safety in piping systems.

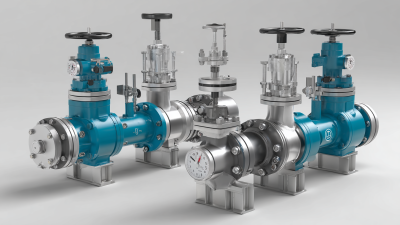

In terms of structure, casting ball valves typically consist of a body made from durable materials such as stainless steel or carbon steel, designed to withstand extreme pressures and temperatures. The valve's internals include a ball, stem, and seat, usually made from materials resistant to wear and corrosion. Functionally, they are favored for on/off control, offering quick and effortless operation with minimal pressure drop. The design allows for easy maintenance and repair, making casting ball valves a preferred choice in sectors ranging from oil and gas to water treatment, where optimal performance and reliability are paramount.

Casting ball valves are becoming increasingly essential in various industrial applications due to their remarkable advantages. One of the key benefits is their durability and resistance to corrosion, which makes them suitable for use in harsh environments. According to a recent market report by MarketsandMarkets, the global ball valve market is projected to reach USD 12 billion by 2026, driven by the increased demand for reliable and efficient fluid control systems. This highlights the growing reliance on high-quality valves, such as casting ball valves, to ensure optimal system performance.

Another major advantage of casting ball valves is their ease of operation and maintenance. Their simple design allows for quick opening and closing, providing minimal pressure drop and reduced risk of leaks. A study by Valves and Actuators Research indicates that the operational efficiency of industrial systems can improve by up to 25% when utilizing high-performance valves like casting ball valves. This efficiency not only enhances productivity but also lowers operational costs, making these valves a smart investment for industries focused on maximizing output and minimizing downtime.

The market for casting ball valves is experiencing significant growth driven by various industrial trends. According to a recent report by MarketsandMarkets, the global ball valve market is projected to reach $15.2 billion by 2025, growing at a CAGR of 5.8% from 2020 to 2025. This surge can be attributed to the increasing investments in infrastructure development across emerging economies and the rise in demand for efficient fluid control systems in industries such as oil and gas, water and wastewater, and power generation.

One of the primary trends influencing the demand for casting ball valves is the shift towards automation in industrial processes. A report by Research and Markets indicates that the automation market is expected to grow from $200 billion in 2020 to over $300 billion by 2025. As industries increasingly adopt automated solutions for improved operational efficiency, the need for reliable and durable components like casting ball valves becomes paramount. Additionally, the growing emphasis on sustainability and environmental regulations is propelling manufacturers to develop valves that offer enhanced performance and reduced emissions, further driving demand in the market.

Casting ball valves are pivotal components in various industrial applications, providing efficient flow control and minimal pressure drop. To maintain their optimal performance, regular maintenance is crucial. According to a recent report by the Flow Control Industry Association, well-maintained ball valves can achieve a remarkable efficiency rate of over 95%. This underscores the importance of adhering to best practices for upkeep, including regular inspection, cleaning, and lubrication of the valve's components.

The implementation of a predictive maintenance strategy is also beneficial. Utilizing advanced monitoring technologies can detect early signs of wear or malfunction, helping to prevent costly downtime. The Valve Manufacturers Association estimates that incorporating such technologies can reduce maintenance costs by up to 30% and extend the lifespan of the valve significantly. Additionally, establishing a routine maintenance schedule that includes proper torque settings and gasket inspections can further enhance the performance and reliability of casting ball valves, ensuring they operate at peak efficiency in demanding environments.

Casting ball valves are essential components in various industrial applications, offering distinct advantages over other valve types. When comparing casting ball valves to options such as gate or globe valves, it becomes evident that casting ball valves provide superior flow control and reduced pressure drop. Their design allows for and minimal leak potential, making them a reliable choice for critical processes.

One significant benefit of casting ball valves is their durability and resistance to corrosion, particularly when made from stainless steel or alloy-based materials. This resilience ensures longevity in harsh operating conditions, which is paramount in sectors like oil and gas, water treatment, and chemical processing. The market trends indicate a growing preference for casting ball valves, as industries seek efficient solutions that enhance performance while reducing maintenance costs.

Tips: When selecting a casting ball valve, consider the specific material that aligns with your application's demands. Stainless steel is ideal for high-temperature environments, while cast iron suits more moderate conditions. Always assess the valve's specifications to ensure optimal performance and compatibility with your system, ultimately leading to improved operational efficiency.