-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

Trunnion Mounted Valves are essential in various industrial applications, particularly in oil and gas, water management, and chemical processing. According to the Global Market Insights report, the valve market is projected to surpass $85 billion by 2025. This growth highlights the increasing demand for efficient flow control systems and the pivotal role of these valves in maintaining operational safety and reliability.

Trunnion Mounted Valves offer numerous advantages. They provide greater support and stability compared to floating ball valves, making them ideal for high-pressure and high-temperature environments. Reports indicate that the energy sector heavily relies on these valves for their durability and performance. However, improper selection or installation can lead to significant operational issues, underscoring the need for careful consideration in application.

While many applications benefit from Trunnion Mounted Valves, challenges remain. For instance, the initial cost can be higher than other valve types. Businesses must weigh long-term benefits against upfront expenses. Achieving the right balance is crucial for optimal performance and cost-efficiency. Proper training and maintenance can further ensure reliability.

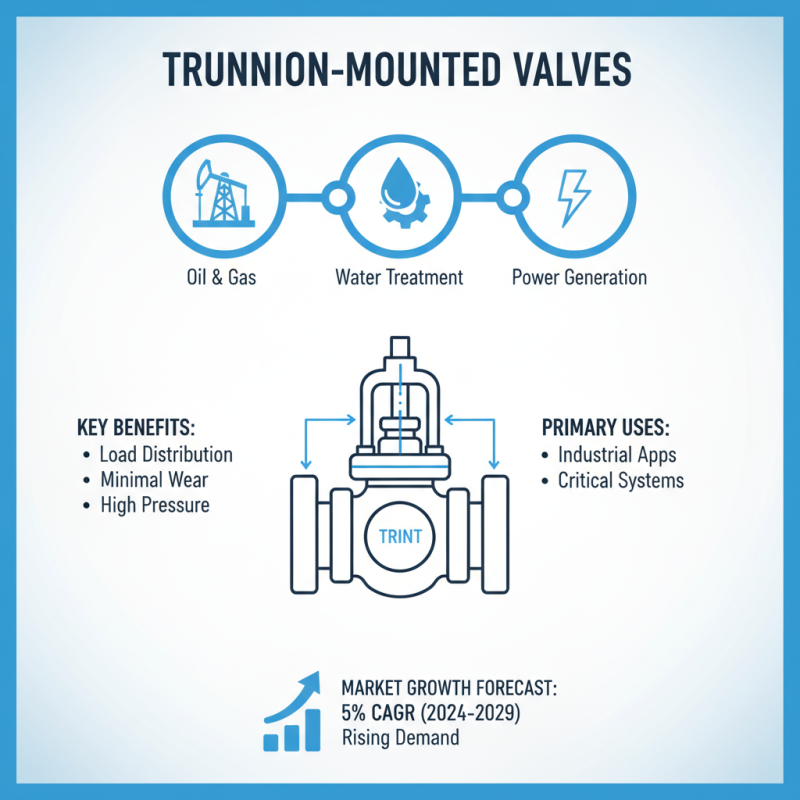

Trunnion mounted valves are essential in various industrial applications. Their design allows for better load distribution and minimal wear under high pressure. Industries like oil and gas, water treatment, and power generation commonly use these valves. According to a recent industry report, the market for trunnion mounted valves is expected to grow at a CAGR of 5% over the next five years. This growth indicates a rising recognition of their benefits.

In practice, trunnion mounted valves provide reliable sealing under demanding conditions. They are often used in situations involving large flow rates and high pressures. However, improper installation or maintenance can lead to failures. Regular inspections and adherence to guidelines can mitigate these risks.

**Tip:** Always consult with a valve expert to determine the right type for specific applications. Choosing the wrong valve may lead to significant operational inefficiencies. Another point to consider is the importance of compatibility with the fluids being controlled, as chemical interactions can impact valve longevity.

Trunnion mounted valves are pivotal in many industrial settings. These valves come with a unique design. The trunnion supports the ball, allowing for smoother operation. This design reduces friction and wear. Consequently, they provide longer service life. Such features make them ideal for high-pressure applications.

One key feature is their ability to handle larger volumes. Trunnion mounted valves can manage significant flow rates efficiently. They often incorporate a double block and bleed feature. This enhances safety and reliability in critical processes. Moreover, these valves are less prone to vibration. However, proper installation is crucial; incorrect alignment can lead to performance issues.

Another point to consider is maintenance. Although durable, trunnion mounted valves can require periodic checks. Over time, seals may wear out. Regular inspections help identify leaks or potential failures. Understanding these nuances can improve operational efficiency. Information on installation and maintenance is sometimes lacking. Users must ensure they have the right guidance to avoid pitfalls.

Trunnion mounted valves are crucial in industrial settings. They provide reliability under high pressure and temperature. The materials used play a key role in their performance and lifespan. Common materials in these valves include stainless steel, carbon steel, and various alloys.

Stainless steel offers excellent corrosion resistance. It's a preferred choice in industries handling aggressive substances. Carbon steel, while more affordable, may not withstand harsh environments. On the other hand, special alloys combine durability and strength. They can endure extreme conditions but often come at a higher cost.

Choosing the right material is essential. It determines the valve's ability to function efficiently. However, not all materials suit every application. Some might fail under specific conditions, leading to costly downtime. Reflecting on these choices can enhance decision-making for future projects.

Trunnion mounted valves have gained popularity in industrial applications due to their unique advantages. These valves feature a strong supporting structure that enhances stability and performance. They provide improved control over flow, which is essential in various processes. The design minimizes side loading forces, reducing wear and tear.

One significant advantage is their ability to handle high pressures. This design allows for a more accurate seal. Leak prevention is critical in many industries. Trunnion mounted valves also often require less torque for operation, making them easier to handle. Their durability means less frequent replacements. This can save costs over time.

However, some challenges do exist. Installation can be complex. Proper alignment is crucial for optimal performance. If not addressed, it may lead to malfunctions. Regular maintenance is necessary to ensure their longevity. The initial investment can be high, but the long-term benefits often outweigh the costs. Understanding these aspects is important for making informed choices.

Trunnion mounted valves find extensive use in various industrial applications. Their design allows for high pressure and temperature limitations. This attribute makes them ideal for oil and gas industries. They provide reliable performance in harsh conditions. For instance, the upstream sector relies on these valves for flow control. Often, the valves handle fluctuating pressure. This presents challenges that require careful monitoring.

In chemical manufacturing, trunnion mounted valves play a critical role. They manage aggressive substances, ensuring process safety. These valves help maintain system integrity. Additionally, they are important in water treatment facilities. They regulate water flow and ensure efficient operations. However, there are common issues to consider. These can include wear and tear over time. Operators often need to conduct regular inspections.

Power generation is another significant field for trunnion mounted valves. They control steam flow in turbines, which is crucial. However, they are not free from challenges. They can be affected by temperature changes. Poor maintenance practices can lead to failures. Proper training is essential for those managing these valves. Understanding their function can help prevent costly downtime.

| Valve Type | Application | Industry | Pressure Rating | Temperature Range |

|---|---|---|---|---|

| Ball Valve | On/Off control | Oil & Gas | Class 150-2500 | -50°C to +180°C |

| Butterfly Valve | Flow regulation | Water Treatment | Class 150-300 | -10°C to +120°C |

| Gate Valve | Isolation | Chemical Processing | Class 150-600 | -29°C to +200°C |

| Check Valve | Backflow prevention | Power Generation | Class 150-3000 | -40°C to +150°C |

| Globe Valve | Flow control | HVAC Systems | Class 150-600 | -29°C to +230°C |