-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

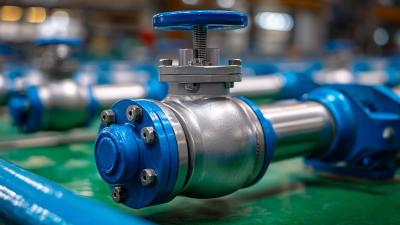

In the world of fluid control, Soft Seat Ball Valves stand out for their unique design and efficiency. John Smith, a renowned valve expert, states, "Soft Seat Ball Valves offer unbeatable sealing performance." This technology uses a soft material in the seating area, ensuring minimal leakage and a reliable shutoff.

The benefits are clear: improved durability, reduced maintenance, and cost-effectiveness. These valves can handle various fluids, making them versatile in many industries. In applications where precision is key, such as in pharmaceuticals or food processing, the choice of a Soft Seat Ball Valve becomes crucial.

Yet, one must consider potential drawbacks. While these valves excel in many scenarios, they may not withstand extreme temperatures. A deeper understanding of material choices is essential for optimal performance. Each application requires careful evaluation to ensure a perfect fit. The world of Soft Seat Ball Valves is complex but rewarding with the right knowledge.

Soft seat ball valves are widely used in various industries due to their versatility. These valves are designed with a soft material, often rubber or plastic, on the sealing surface. This design enhances sealing performance, making them ideal for applications involving liquids and gases. Common types include trunnion ball valves and floating ball valves. Each type serves unique purposes, particularly in oil, gas, and water industries.

Applications of soft seat ball valves are extensive. In water treatment plants, they control the flow of water effectively, minimizing leaks. In the chemical industry, they handle corrosive substances safely. These valves provide excellent sealing capabilities, even under varying pressure and temperature conditions. This adaptability makes them essential in pipeline systems.

**Tips:** When selecting a soft seat ball valve, consider the specific application. Different materials may be required based on the fluid's properties. Regular maintenance is essential; wear and tear can lead to leaks, compromising efficiency. Monitor the valve's performance to identify any potential issues early.

In some cases, not all soft seat designs will match specific system requirements. It’s crucial to assess compatibility with existing pipeline systems. Not addressing these details could lead to inefficiencies or malfunctions down the line. Always take the time to evaluate the potential drawbacks to ensure the best choice for your needs.

| Feature | Description | Benefits | Common Applications |

|---|---|---|---|

| Leak-proof Design | Utilizes soft seat materials to ensure a tight seal. | Prevents leakage, reducing waste and hazards. | Water supply systems, chemical processing. |

| High Flow Capacity | Features a large bore design for minimal flow resistance. | Enhances system efficiency and performance. | Oil and gas pipelines, irrigation systems. |

| Corrosion Resistance | Constructed from materials that resist corrosive fluids. | Increases longevity and reduces maintenance costs. | Chemical plants, waste management facilities. |

| Easy Operation | Designed for manual or automated operation with minimal effort. | Improves user experience and reduces operational errors. | HVAC systems, water treatment. |

| Temperature and Pressure Ratings | Able to handle a wide range of temperatures and pressures. | Versatile for various industrial applications. | Power generation, food and beverage processing. |

Soft seat ball valves are crucial in various applications due to their unique materials and design. The primary feature of these valves is the soft seat, often made from elastomers or plastics. This construction allows for a tight seal, minimizing leakage. Users appreciate this design, particularly in industries where fluid control is essential.

In terms of materials, soft seat ball valves can be made from PTFE, EPDM, or rubber. PTFE, for instance, is chemically resistant and suitable for harsh environments. However, it may not fare well in high-pressure situations. It’s essential to choose the right material for your specific application. Debates arise over the best choice, highlighting that there isn’t a one-size-fits-all solution.

Tips: Always evaluate the operating conditions. Consider temperature and pressure. Selecting the wrong type can lead to failure. Regular maintenance checks can reveal potential issues early. This can save time and resources down the line. Reflect on the specific needs of your system to avoid unnecessary complications.

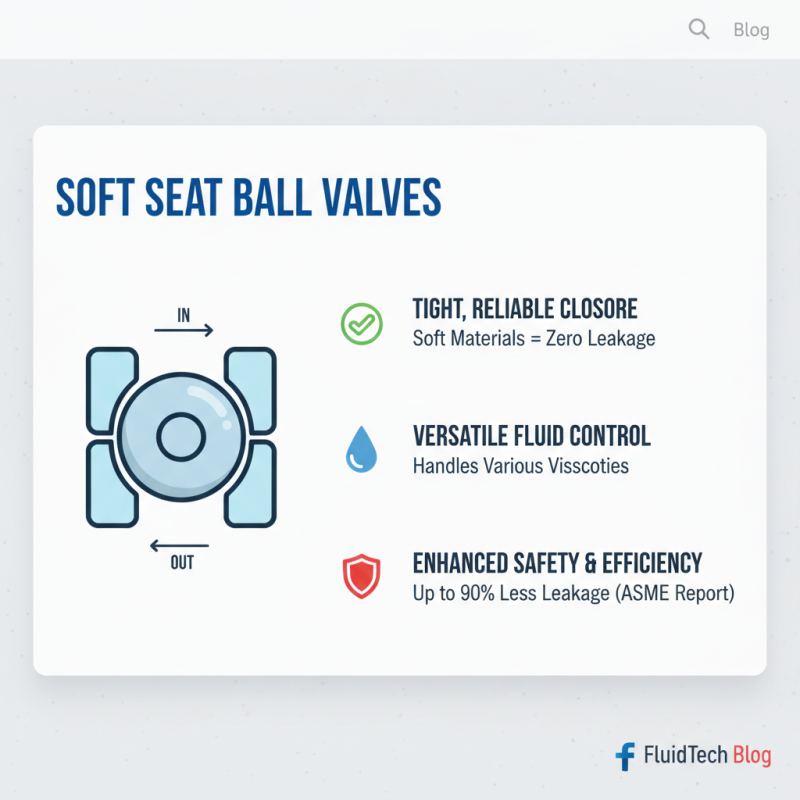

Soft seat ball valves have gained popularity in fluid control systems for several reasons. Their construction uses soft materials for sealing, providing a tight, reliable closure. This is particularly beneficial in handling fluids with varying viscosities. A report from the American Society of Mechanical Engineers notes that soft seat valves can reduce leakage rates by up to 90%. This feature greatly enhances operational efficiency and safety.

Using soft seat ball valves comes with several advantages. They are less prone to wear over time compared to hard-seated alternatives. This longevity is particularly important in industries such as chemical processing, where reliability is crucial. Another advantage is their ability to handle a wider range of temperatures. For instance, soft seat valves can operate effectively in temperatures from -20°C to 140°C. However, it’s essential to assess compatibility with specific fluids, as some chemicals may degrade soft materials over time.

Tips: Always consult the manufacturer’s specifications for temperature and pressure ratings. Regular maintenance checks can help identify wear and tear early. Additionally, training staff on proper installation and usage is key to maximizing lifespan. In some cases, the initial cost savings might lead to higher repair costs later. Hence, careful planning is vital for successful implementation.

Maintaining soft seat ball valves is crucial for their longevity and efficiency. Regular inspections can identify wear and tear. Check for leakages and corrosion. Addressing issues early prevents bigger problems later.

Ensure that the handle moves smoothly. Sticky handles indicate potential issues with the seat or stem.

Cleaning is another essential aspect. Use gentle detergents and avoid abrasive materials. A soft cloth does wonders for eliminating dirt. Dirt build-up can hinder valve operation. When needed, apply appropriate lubricants. This keeps moving parts functional and prevents rust.

Periodic testing of the valve's operation is also important. Ensure it opens and closes fully. Inconsistent operation can signal a problem. Remember, even the best valves require attention. Regular maintenance may seem tedious, but it pays off. Neglect may lead to costly repairs and downtime. Reflect on whether you’ve prioritized these tasks. Balancing efficiency and upkeep is vital.

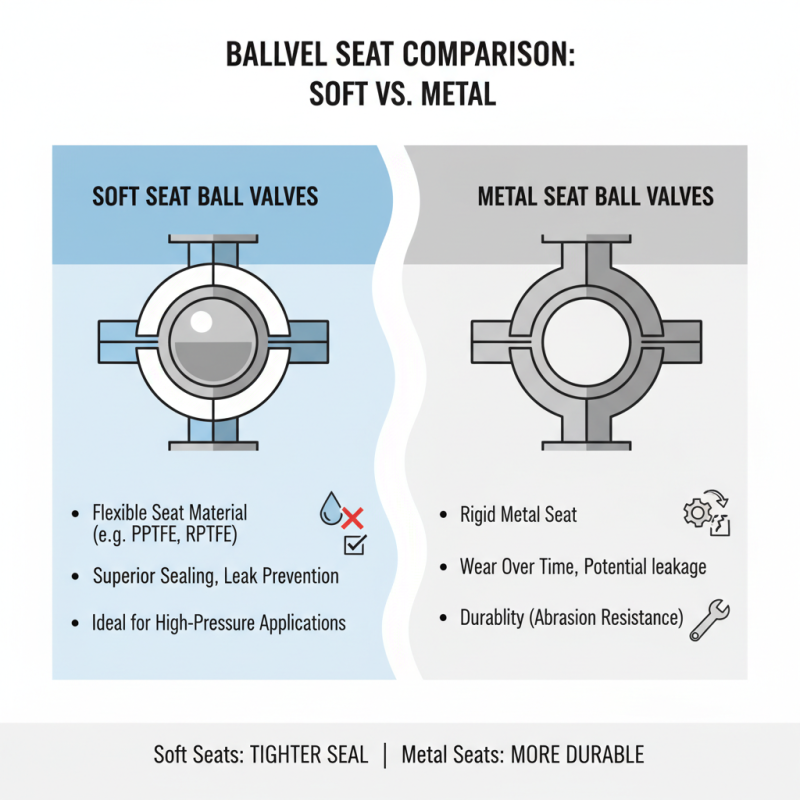

When comparing soft seat ball valves to traditional metal seat options, several key differences emerge. Soft seat ball valves are designed with seats made from flexible materials, offering superior sealing capabilities. This design helps prevent leaks in high-pressure environments. In contrast, metal seat valves can experience wear over time, leading to potential leakages. The durability of metal may seem appealing, but it can often sacrifice the tight seals that soft seats provide.

One notable feature of soft seat ball valves is their ability to handle various fluid types. They are more resistant to corrosive substances. Additionally, the maintenance requirements are often lower, helping to reduce overall operating costs. However, some may argue that soft seats can be less durable in extreme temperatures compared to metal counterparts. This is a critical consideration for specific applications. While soft seat valves excel in many environments, their performance should always be evaluated based on the specific use case.

In terms of cost, soft seat ball valves might be more budget-friendly initially. However, it's essential to look at longevity and efficiency. Investing in quality can result in long-term savings. Users need to weigh these aspects carefully. Some may overlook the potential trade-offs between performance and price, missing opportunities for better systems. A reflective approach can lead to smarter decisions in valve selection, ensuring optimal utility in various industries.