-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

When discussing industrial valves, the "Ball Valve Wafer Type" stands out. Its unique design offers seamless installation between flanges. This valve type combines efficiency with simplicity, making it a top choice for various applications. Users appreciate its compact structure and lightweight features.

The benefits of the Ball Valve Wafer Type go beyond just physical attributes. It enhances flow control and reduces leakage risks. In many cases, users report improved operational performance. However, some may overlook the importance of regular maintenance. Ignoring this aspect can lead to unexpected failures.

This exploration sheds light on the crucial features of the Ball Valve Wafer Type. We will examine its advantages and potential drawbacks. Understanding these factors can lead to better decision-making for industries relying on valve systems.

Wafer type ball valves are unique in their design. They feature a thin, disc-like shape, making them compact and lightweight. This design allows for easy installation and maintenance. Wafer ball valves fit between flanges, eliminating the need for heavy-bodied valves. This can reduce costs and space requirements in piping systems.

One key benefit of wafer ball valves is their low operating torque. This makes them easier to operate, especially in larger sizes. Their tight sealing abilities prevent leaks effectively. Wafer valves are also valued for their versatility. They handle various media, including liquids and gases. However, installation must be done correctly to avoid issues. Misalignment or improper fitting can lead to performance problems.

It's essential to consider the material of the valve. Different materials may affect durability and compatibility with fluids. Users should also check pressure ratings. This ensures they select the right valve for their specific applications. Though wafer ball valves are efficient, they are not a one-size-fits-all solution. Thoughtful consideration is needed for optimal results.

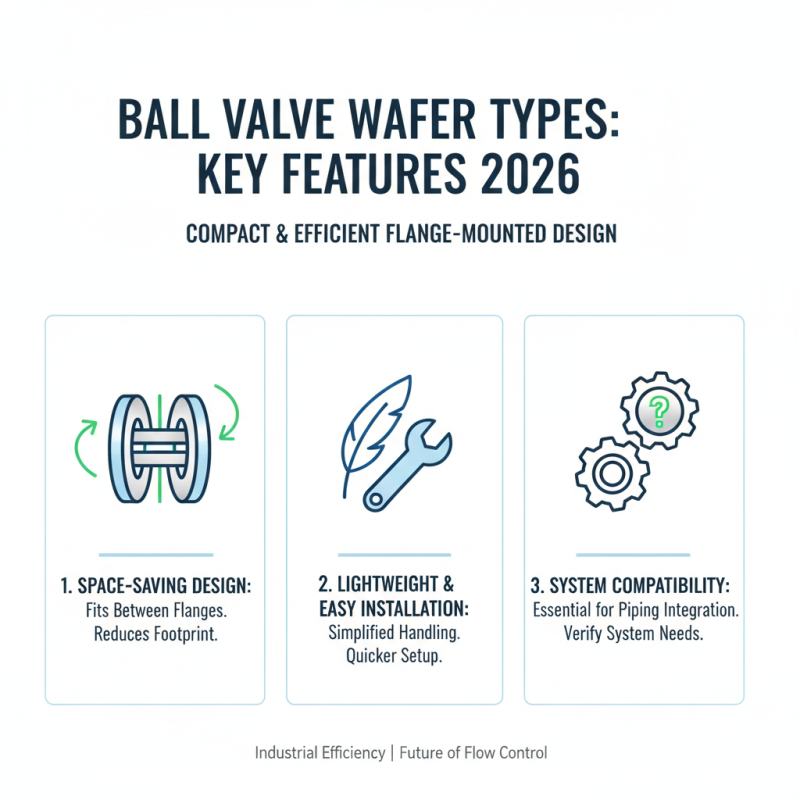

When considering the best ball valve wafer types in 2026, several key features stand out. These valves are specifically designed to fit between flanges. Their compact size is one of their main advantages. They save space and reduce weight, making installation easier. Many industries favor these valves for that very reason. However, one must consider the compatibility with specific piping systems.

A significant benefit of wafer ball valves is their excellent flow characteristics. They provide minimal resistance, leading to better energy efficiency. Their design allows for easy maintenance, as they can often be serviced without removing the entire system. However, not all wafer valves perform equally. Some may develop issues over time. Regular checks are necessary to ensure reliability.

Another aspect worth reflecting on is the material selection. The durability of these valves hinges on the right materials. While many are constructed from robust alloys, some options may not withstand harsh environments. It’s crucial to assess the specific needs of your application. Choosing the wrong type can lead to failures and increased costs. Therefore, careful consideration is essential before making a decision on wafer type ball valves.

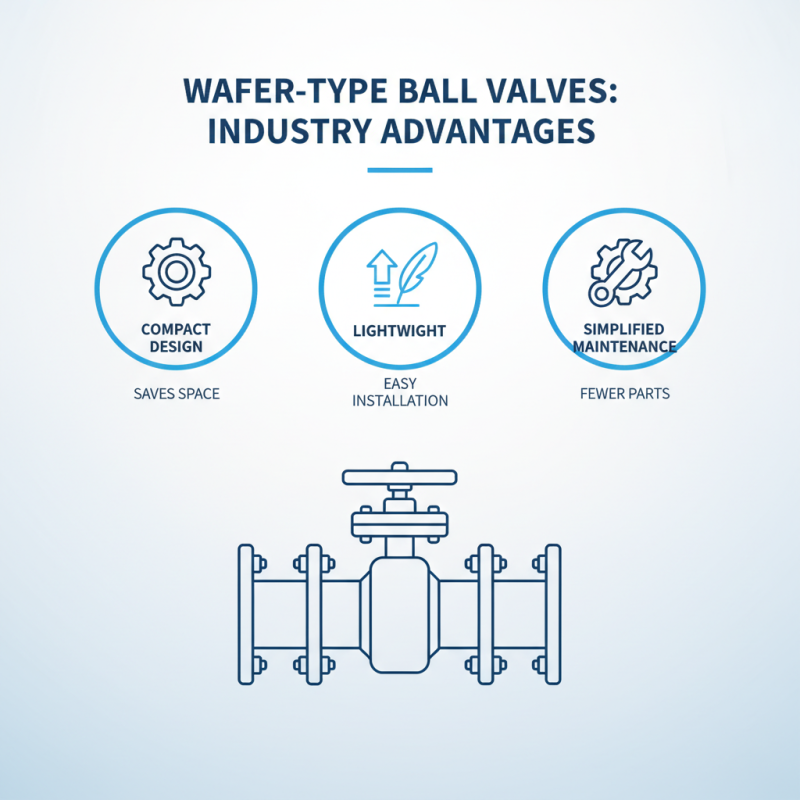

Wafer type ball valves are increasingly popular in various industries. Their compact design is a major advantage. They fit easily between flanges, saving space. This type of valve is lightweight, which simplifies installation. Maintenance becomes less complicated, too. With fewer parts, there’s less to worry about.

One notable feature is their reliable sealing. They provide excellent flow control, minimizing leaks. Many operators appreciate this reliability. However, not all wafer valves are created equal. Quality can vary significantly across manufacturers. Choosing the right one requires careful thought.

Cost-effectiveness is another perk. Wafer type ball valves can be less expensive compared to other designs. This makes them attractive for projects with tight budgets. Yet, using the cheapest option might lead to future issues. It's essential to balance cost with quality and performance. Think about long-term benefits before making a decision.

Wafer-type ball valves have unique features that differentiate them from other valve types. They are compact and lightweight, making them easier to install in tight spaces. Compared to gate and globe valves, they provide a straight-through flow path. This design reduces pressure drop and enhances flow efficiency. In many applications, these valves offer better performance with lower energy consumption.

Despite these advantages, there are some drawbacks. Wafer ball valves may not handle high-pressure applications as effectively as some other types, such as globe valves. They can also be more sensitive to temperature variations. In situations where extreme conditions are present, careful consideration is essential.

**Tips:** When selecting a valve, always assess the working environment. Ensure the valve's specifications match your application needs. Consider conducting regular maintenance checks to extend the valve's life. A proactive approach can prevent costly downtime due to valve failure.

| Feature/Benefit | Ball Valve Wafer Type | Gate Valve | Globe Valve | Check Valve |

|---|---|---|---|---|

| Compact Design | Yes | No | No | Yes |

| Low Torque Requirement | Yes | No | No | N/A |

| Quick Opening/Closing | Yes | Slow | Moderate | Moderate |

| Versatile Application | Yes | Limited | Limited | Specific |

| Maintenance | Low | Moderate | High | Low |

| Cost-Effectiveness | High | Moderate | High | Low |

Wafer type ball valves have a wide range of applications across various industries. These valves are compact and lightweight, making them ideal for space-restricted areas. One common application is in water treatment plants. They efficiently control flow and reduce pressure drops. The design allows for easy installation between flanges.

In the chemical industry, wafer type ball valves are crucial. They handle aggressive fluids with varying viscosities. The sealing mechanism ensures minimal leakage, enhancing safety. In HVAC systems, they support temperature control and maintain system efficiency. The versatility of wafer type valves makes them suitable for both harsh environments and standard conditions.

Maintenance can be challenging. Operators need to ensure that the valves are regularly checked for wear. Accessibility can also be an issue, especially in tight installations. It's vital to balance performance with maintenance needs. Regular inspections help prevent unforeseen failures. Investing time in maintenance pays off in improved reliability.