-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In today’s industrial landscape, the choice of valve materials is crucial. The “Forged Steel Ball Valve” has gained substantial recognition for its robust performance and reliability. According to a recent market analysis, the global valve market is projected to reach $91.6 billion by 2026. This growth reflects the increasing demand for durable and efficient valve solutions in various sectors.

The benefits of forged steel ball valves are numerous. These valves are known for their ability to withstand high pressure and temperature, making them suitable for challenging environments. A report by the International Journal of Mechanical Engineering highlights that high-performance valves can enhance system efficiency by up to 20%. However, not all applications may benefit equally from these valves, emphasizing the need for careful selection.

Despite their advantages, it’s essential to evaluate application-specific requirements. Some industries may encounter challenges such as corrosion, which might not be fully addressed by forged steel. Understanding these limitations can be essential in ensuring operational effectiveness. Thus, while the forged steel ball valve presents significant advantages, continuous evaluation, and adaptability remain vital for optimal performance in industrial applications.

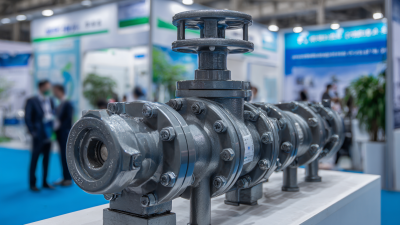

Forged steel ball valves are essential in high-pressure systems. Their strong construction holds up under intense conditions. They resist corrosion and provide a reliable seal. This reliability is crucial in industries like oil and gas, where safety is a priority. Choosing the right valve can make a significant difference in operations.

Tips: Always consider the valve size. A too-small valve can restrict flow. Look for durable materials that suit your environment. For instance, stainless steel may be ideal in corrosive settings.

Forged steel ball valves offer quick flow control. Their design allows for minimal pressure drop. However, installations may require specific fittings. If improperly installed, these valves can leak. Regular maintenance can help identify potential issues early. Also, avoid over-tightening, as it may cause damage. Proper adjustments are crucial for optimal performance in high-pressure conditions.

| Feature | Description | Advantages |

|---|---|---|

| Durability | Forged steel construction provides higher resistance to wear and tear. | Longer service life and lower maintenance costs. |

| Pressure Handling | Designed to withstand high pressure and extreme temperatures. | Safe operation in critical applications. |

| Flow Efficiency | Provides a straight through flow path with minimal turbulence. | Improved energy efficiency and reduced wear on connected systems. |

| Tight Sealing | Precision engineered to ensure a tight seal when closed. | Minimized leakage and maximized system integrity. |

| Versatility | Applicable in a wide range of industries and systems. | Suitable for diverse applications including oil, gas, and water. |

Forged steel ball valves are renowned for their durability and longevity in industrial applications. These valves often withstand extreme temperatures and pressures. They resist wear and corrosion better than many alternatives. This resilience significantly extends their lifespan, often exceeding decades when properly maintained.

A quantitative analysis reveals that forged steel ball valves outperform others in tests. Studies show they endure over 100,000 cycles without failing. However, this doesn't guarantee flawless performance in all conditions. Environmental factors can still impact their reliability. Regular inspections become crucial to prevent unexpected failures.

Moreover, while the initial investment may be higher, long-term cost savings are evident. Reduced frequency of replacements leads to lower maintenance costs. Yet, one must be cautious. Misjudging the installation process can negate these benefits. Therefore, proper training and understanding of the equipment are essential for maximizing efficiency.

This chart demonstrates the quantitative benefits of forged steel ball valves in key performance areas including corrosion resistance, temperature tolerance, pressure rating, and overall service life. Each category is rated on a scale from 0 to 100, showcasing the superior qualities that make forged steel ball valves a preferred choice in industrial applications.

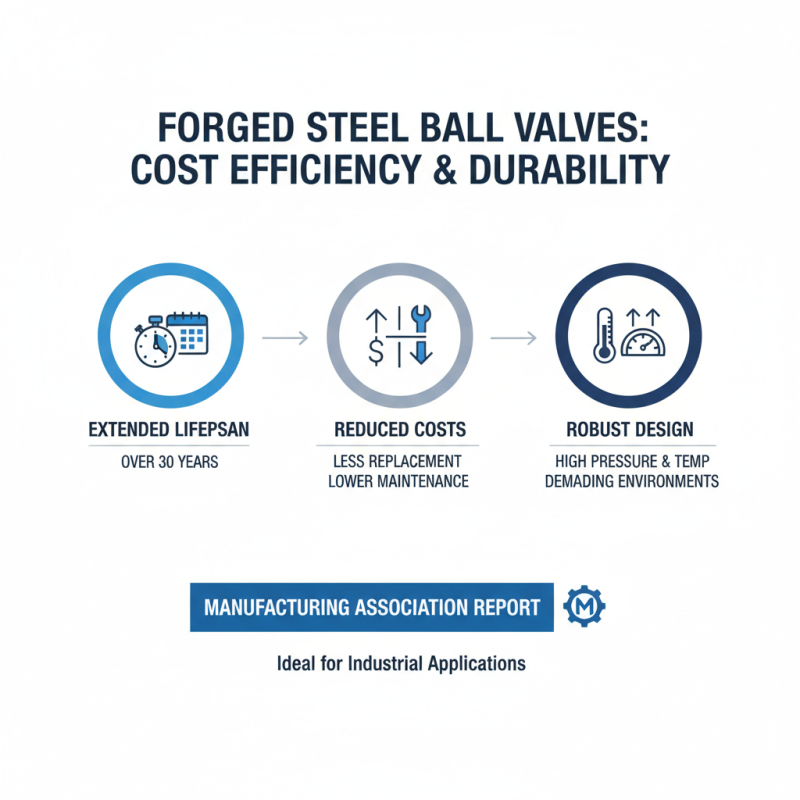

Forged steel ball valves have gained popularity in industrial applications due to their impressive cost efficiency. According to a report from the Manufacturing Association, the average lifespan of forged steel ball valves is over 30 years, which leads to significant long-term savings. Companies can expect reduced replacement frequency and lower maintenance costs. These valves are designed to withstand high pressure and temperature, making them ideal for demanding environments.

Maintenance costs can be a hidden challenge. While initial investments may seem high, the durability of forged steel valves mitigates these concerns. An industry study revealed that organizations often save up to 20% annually in operational costs by utilizing high-quality forged steel options. In contrast, cheaper alternatives might require frequent replacements, accumulating costs over time.

Moreover, the overall efficiency of operations improves. A diligent focus on reliable performance can increase productivity. However, companies must understand that not all forged steel valves are created equal. It's crucial to analyze specific conditions and applications. Some industries might overlook vital aspects, leading to miscalculations in cost savings. The potential for reflecting on one’s choices is vital as industries evolve.

Forged steel ball valves are gaining traction across various industrial sectors. Their robust construction provides excellent durability, making them ideal for high-pressure environments. Many industries, such as oil and gas, water treatment, and chemical processing, rely on these valves for effective flow control.

In the chemical processing industry, forged steel ball valves are often exposed to harsh conditions. They handle corrosive substances and extreme temperatures. This versatility allows them to function effectively where other materials might fail. However, some users report challenges in maintaining these valves. Regular inspections and maintenance are vital to avoid corrosion and mechanical failure.

Energy production facilities also benefit from forged steel ball valves. These settings require valves that can withstand high pressures and temperatures. The reliability of these components is crucial. Despite their advantages, improper installation can lead to leaks. Awareness of the potential for installation errors is necessary for safe operations.

Forged steel ball valves are vital in many industrial applications. They boast high performance and reliability, especially in critical services. The design ensures that these valves can withstand extreme pressures and temperatures. Their robust construction minimizes the risk of leaks, which is essential in hazardous environments. Proper installation and maintenance are paramount to achieve optimal performance.

In critical situations, small failures can lead to significant issues. Choosing forged steel ball valves often means having a long-lasting solution. However, users sometimes overlook the importance of regular inspection. Without it, wear and tear can compromise the valve's functionality. The performance might decline, leading to unexpected downtimes.

The reliability of these valves is evident in various sectors, such as oil and gas, water treatment, and chemical processing. Many users appreciate their ability to handle corrosive substances. But, they must be mindful of the operating conditions. Matching the valve specifications with system requirements is crucial. Ignoring these details could result in costly repairs and safety hazards. Proper education on valve selection can ensure their longevity and effectiveness.