-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

The Double Block Bleed Valve (DBBV) has emerged as a crucial component in modern industrial applications, particularly in sectors such as oil and gas, chemical processing, and water treatment. With the global industrial valves market projected to reach $98.75 billion by 2024, the integration of advanced valve technologies like DBBVs is increasingly vital for enhancing operational safety and efficiency.

These valves provide a reliable means of isolating sections of a pipeline while facilitating bleeding and maintenance, thus minimizing the risk of leakage and environmental hazards. Notably, a report by Grand View Research indicates that the demand for advanced valve solutions will continue to surge as industries prioritize safety protocols and compliance with stringent regulations.

This article delves into the multifaceted benefits and diverse applications of Double Block Bleed Valves, highlighting their role in fostering safer and more efficient industrial processes.

Double block bleed valves (DBBVs) are increasingly recognized for their vital role in hazardous material handling, bolstering safety compliance across various industries. According to the 2022 report from the American Petroleum Institute, improper valve operation accounts for nearly 30% of safety incidents in the oil and gas sector. DBBVs significantly mitigate these risks by ensuring that both the upstream and downstream pipeline sections are isolated from each other during maintenance, preventing accidental leakages and contamination.

Moreover, DBBVs enhance safety protocols by providing an effective bleed function, which allows for the safe evacuation of trapped fluids, thereby reducing the chance of hazardous spills. A recent study by the International Society of Automation highlighted that facilities employing DBBVs reported a 25% reduction in emergency response incidents related to valve failures, showcasing their importance in maintaining compliance with stringent safety standards.

Tips: Always perform regular maintenance checks on your double block bleed valves to ensure optimal performance and reliability. Additionally, training personnel on the correct operation and inspection of these valves can further enhance safety measures within your facility.

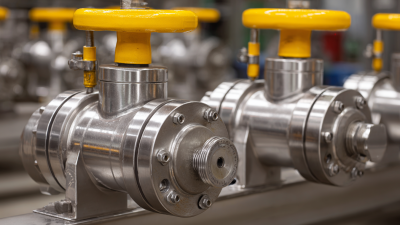

Double block bleed valves are increasingly vital in the oil and gas industry, particularly for pipeline integrity management. These valves enhance safety and reliability by providing a robust isolation method, allowing for maintenance activities without interrupting operations. Their ability to prevent any leakage during pipeline inspections ensures compliance with environmental regulations and protects assets from potential disasters, such as those seen in historical incidents like the Piper Alpha tragedy.

Recent developments in high-integrity valve technology align with the demanding conditions of modern oil and gas extraction, including projects in challenging environments like the North Sea. The need for valves that can withstand high pressure and temperature has spurred innovations in design and functionality. Additionally, new investments in the pipeline sector demonstrate a commitment to improving integrity management, with companies expanding their capabilities to include advanced valve systems that enhance operational safety and efficiency. The strategic implementation of double block bleed valves not only mitigates risks but also ensures that pipeline systems operate at optimal performance levels.

Double block bleed valves (DBBVs) play a pivotal role in enhancing efficiency in process control operations across various modern industries. These valves are designed to provide a reliable barrier against leaks and ensure that maintenance activities can be performed safely without contaminating the environment or endangering personnel. By integrating double block and bleed functionalities, industries can effectively isolate sections of their process systems. This minimizes the risk of overpressure or fluid loss during maintenance and operational procedures, which can lead to significant downtime and financial losses.

In process control applications, DBBVs contribute to enhanced operational reliability by allowing for effective pressure management and fluid isolation. They facilitate the safe removal of equipment for inspection or maintenance while ensuring that there is no risk of unintended release of hazardous materials. Additionally, their design helps streamline operations, reducing the need for multiple valves and simplifying the process layout. The integration of DBBVs not only improves safety but also promotes energy efficiency, as they help maintain optimal pressure levels, leading to smoother and more responsive process control systems.

| Application Area | Benefit | Effect on Process Control | Industry Type |

|---|---|---|---|

| Oil and Gas | Prevents leakage | Improves safety and reliability | Energy |

| Chemical Processing | Ensures system integrity | Reduces operational downtime | Manufacturing |

| Water Treatment | Enhances control of flow | Improves efficiency in operations | Environmental |

| Pharmaceuticals | Reduces contamination risks | Maintains product purity | Healthcare |

| Power Generation | Enhances system reliability | Supports consistent output | Energy |

The implementation of double block bleed valves (DBBVs) in modern manufacturing processes offers significant advantages that can justify their investment. As industries increasingly prioritize safety and efficiency, DBBVs play a vital role in maintaining system integrity by allowing for safe isolation and draining of hazardous fluids. This functionality not only enhances process reliability but also reduces the risk of leaks and accidents, which can lead to costly downtime and environmental repercussions. When evaluating their financial implications, the potential savings from decreased maintenance costs and improved safety outcomes often outweigh the initial investment.

Furthermore, as seen in recent industry developments, such as mergers and acquisitions among precision engineering firms, the trend towards integrating advanced technologies and safety measures is gaining momentum. As manufacturers seek to stay competitive, investing in DBBVs can be viewed as a strategic move to align with evolving industry standards. By conducting a thorough cost-benefit analysis, organizations can better understand how this investment not only meets regulatory requirements but also fosters long-term operational efficiency, ultimately leading to enhanced profitability and sustainability in their manufacturing operations.

In modern industries, regulatory compliance and industry standards play a crucial role in ensuring the safety and reliability of high-pressure systems.

Double block bleed valves are essential components that adhere to these rigorous standards, particularly in fire safety applications. These valves provide an effective means of isolating and depressurizing sections of the pipeline, significantly reducing the risk of leaks and explosions that could arise in case of system failures. By ensuring the integrity of high-pressure systems, double block bleed valves contribute to enhanced safety measures and compliance with regulatory requirements.

The implementation of double block bleed valves in industrial settings is not only a compliance measure but also a proactive approach to mitigate potential hazards. Industries such as oil and gas, chemical processing, and power generation recognize the importance of adhering to stringent safety regulations. These valves help maintain operational safety, protect personnel, and prevent environmental contamination. Additionally, regular inspections and maintenance of these valves are essential in meeting industry standards and ensuring optimal performance, making them a key aspect of fire safety in high-pressure environments.