-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

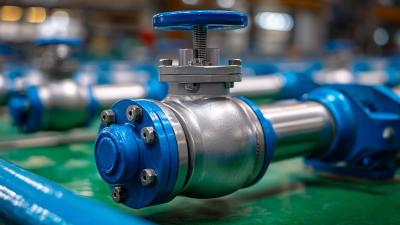

In the realm of modern industrial applications, the Ball Valve Wafer Type has emerged as a pivotal component due to its unique design and operational advantages. This type of valve is specifically engineered to meet the demands of various industries, offering a blend of compactness, efficiency, and ease of installation. Unlike traditional valve designs, the wafer type integrates seamlessly between flanges, reducing the space required and enhancing the overall system efficiency. Furthermore, its lightweight structure allows for significant savings on labor and material costs during installation and maintenance.

With the increasing emphasis on optimizing operational performance and minimizing downtime in industrial processes, understanding the advantages of the Ball Valve Wafer Type is crucial for engineers and decision-makers seeking reliable and innovative solutions for fluid control. This exploration will delve into the key benefits and applications of this valve type, illustrating its role as a cornerstone in contemporary industrial systems.

Wafer type ball valves are becoming increasingly popular in modern industrial applications due to their unique design and functionality. One of the key features of these valves is their compact structure, which allows for easy installation and integration into existing piping systems. This design minimizes the space required, making them ideal for tight spaces commonly found in industrial environments. Additionally, wafer type ball valves provide a reliable sealing mechanism that ensures minimal leakage, contributing to safer and more efficient operations.

Wafer type ball valves are becoming increasingly popular in modern industrial applications due to their unique design and functionality. One of the key features of these valves is their compact structure, which allows for easy installation and integration into existing piping systems. This design minimizes the space required, making them ideal for tight spaces commonly found in industrial environments. Additionally, wafer type ball valves provide a reliable sealing mechanism that ensures minimal leakage, contributing to safer and more efficient operations.

Another significant advantage of wafer type ball valves is their lightweight construction. This feature simplifies handling during installation and maintenance, reducing labor costs. Furthermore, these valves can operate effectively in high-pressure and high-temperature applications, making them versatile for various industrial uses. Their robust construction also leads to a long lifespan, which minimizes the need for frequent replacements.

Tip: When selecting wafer type ball valves, consider the size and pressure ratings for your specific application. Proper alignment during installation is crucial for optimal performance and longevity. Regular maintenance checks can also help in identifying potential issues before they escalate, ensuring uninterrupted operations in your industrial setting.

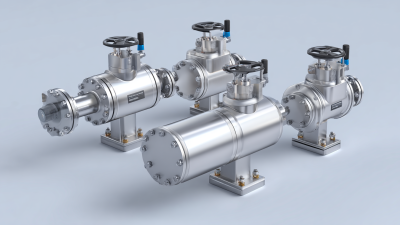

Wafer type ball valves have emerged as a preferred choice in modern industrial applications due to their unique design and performance advantages. When comparing wafer type valves to other common valve designs like lugged or flanged valves, it's essential to consider their compact size and ease of installation.  Wafer type valves are lightweight and occupy less space, making them ideal for systems where minimizing bulk is crucial. Their bi-directional sealing feature enhances versatility, as they can operate effectively in various flow directions without requiring additional components.

Wafer type valves are lightweight and occupy less space, making them ideal for systems where minimizing bulk is crucial. Their bi-directional sealing feature enhances versatility, as they can operate effectively in various flow directions without requiring additional components.

Tips: When selecting a valve type for your application, it’s crucial to assess not just the space but also the pressure and flow characteristics of your system. Wafer type ball valves are particularly suitable for high-flow applications, where standard flanged valves may prove cumbersome. Regular maintenance is also critical; keep an eye on the sealing surfaces to ensure longevity and reliability.

Moreover, the integration of advanced materials in wafer type ball valves enhances their durability and resistance to corrosion, providing a longer lifespan than some traditional valves. This aligns with recent advancements in microfluidics where the choice of materials and fabrication techniques directly affects performance. As industries seek efficient solutions, understanding the comparative advantages of valve designs becomes vital for optimizing system efficiency and reducing costs.

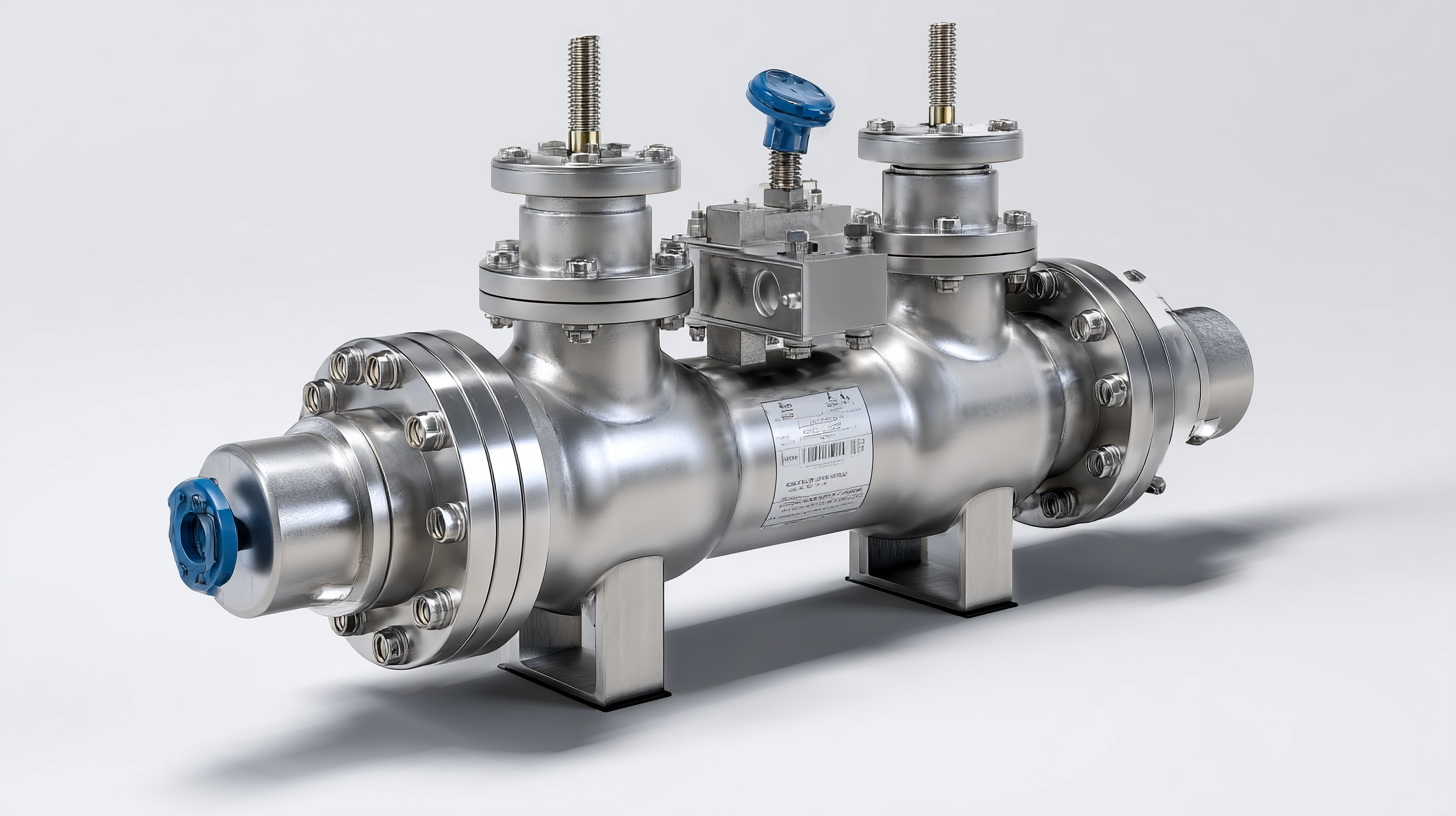

Wafer type ball valves have gained immense popularity across various industries due to their compact design and efficient performance. These valves are ideally suited for applications in water treatment facilities, where managing fluid flow is crucial. The lightweight structure makes them easy to install between flanges, thereby reducing installation time and costs. Additionally, wafer type ball valves provide superior sealing capabilities, ensuring minimal leakage during operation. This is particularly important in sectors such as pharmaceuticals and food processing, where maintaining product integrity and preventing contamination are top priorities.

In the chemical industry, wafer type ball valves are employed for controlling the flow of aggressive fluids and gases. Their robust construction allows them to withstand high pressures and temperatures, making them suitable for harsh environments. Moreover, the quick operation of these valves enhances safety and efficiency in manufacturing processes. Another area benefiting from wafer type ball valves is the HVAC sector, where they play a vital role in regulating heating and cooling systems. Their versatility and reliability make them a preferred choice for engineers looking to optimize performance across many applications.

Wafer type ball valves are increasingly favored in modern industrial applications primarily due to their cost efficiency and maintenance advantages. These valves are designed to be lightweight and compact, which not only cuts down on installation costs but also saves valuable space within piping systems. Their structure allows for quick and easy installation, resulting in reduced labor expenses and minimized downtime during setups.

Maintenance is another critical aspect where wafer type ball valves shine. Their simple design means fewer components and less potential for wear and tear compared to other valve types. This reliability leads to lower long-term maintenance costs, as operators can expect longer service intervals and fewer replacements. Additionally, the ease of access for repairs contributes to shorter maintenance windows, making them an attractive option for industries focused on optimizing productivity and efficiency while managing operational expenditures effectively. With ongoing support from fluid technology divisions, industries can rely on these valves to meet their demanding operational needs.

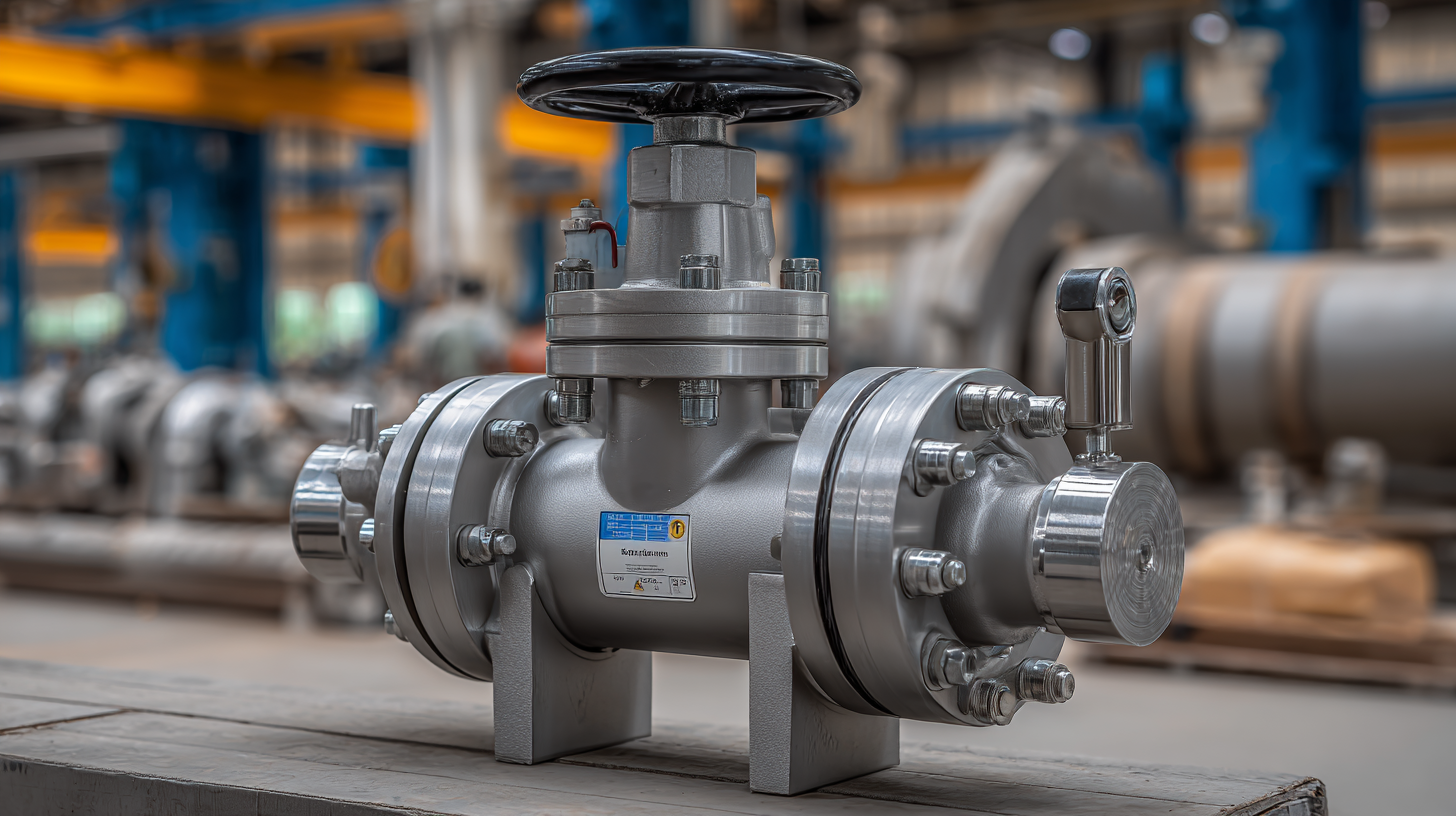

The future of wafer type ball valves in industrial applications is increasingly shaped by advancements in technology and manufacturing processes. Recent developments, such as the successful creation of the world's largest mixed flow pumped storage hydropower unit's ball valve castings, showcase the capabilities and potential of these valves in large-scale energy projects. With their compact design and effective sealing, wafer type ball valves are becoming essential in managing the complexities of modern water and energy distribution systems.

Tips: When considering wafer type ball valves for your applications, evaluate the pressure and temperature ratings to ensure compatibility with your systems. Additionally, selecting high-quality materials can enhance the valve's durability and performance, especially in demanding environments like pumped storage hydropower stations.

Moreover, the recognition of companies specializing in fluid control technology marks a trend toward specialized and innovative manufacturers in the valve industry. As these firms invest in R&D, we can expect breakthroughs that further optimize efficiency and reliability. Emphasizing automation and digital manufacturing, they aim to meet the evolving needs of sectors such as energy production, thereby driving the adoption of wafer type ball valves in even broader industrial contexts.