-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In recent years, the demand for efficient and reliable control systems in industrial applications has surged, highlighting the significance of innovative valve technologies. Among these, the Pneumatic Operated Ball Valve has emerged as a pivotal component, known for its rapid response time and minimal pressure drop, which enhances system performance. According to a report by MarketsandMarkets, the global market for pneumatic valve automation is projected to grow from USD 10.45 billion in 2021 to USD 14.67 billion by 2026, reflecting an annual growth rate of over 6%. This growth is driven by industries seeking to enhance operational efficiency and reduce energy consumption. The inherent design of Pneumatic Operated Ball Valves allows for precise flow control, making them ideal for demanding applications in sectors such as oil and gas, chemicals, and water treatment. As industries continue to prioritize automation and precision, understanding the advantages of these valves will be crucial for optimizing processes and achieving sustainability goals.

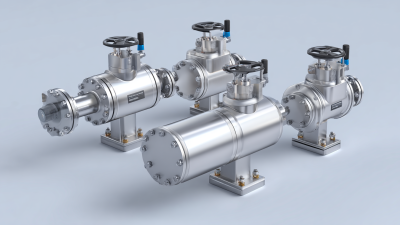

Pneumatic operated ball valves are pivotal in industrial processes that require precise control and reliability. There are several types of these valves utilized across various sectors, each tailored for specific applications.

The most common types include three-way ball valves, which are extensively used in applications requiring flow diversion or mixing. According to a report from Frost & Sullivan, the demand for three-way valves is projected to grow at a rate of 5.6% annually, indicative of their increasing role in industrial automation.

Another prevalent type is the full-port ball valve, which ensures minimal pressure loss and maximum flow efficiency. This design is favored in industries like oil and gas, where maintaining high flow rates is crucial. The Offshore Technology Conference reports that nearly 40% of the global valve market by 2025 will comprise full-port valves due to rising demand in energy sectors. Additionally, the use of actuated ball valves, which integrate with control systems for automated processes, is accelerating, with a projected increase in adoption by 8.3% yearly, as companies seek to enhance operational efficiency and safety in their facilities.

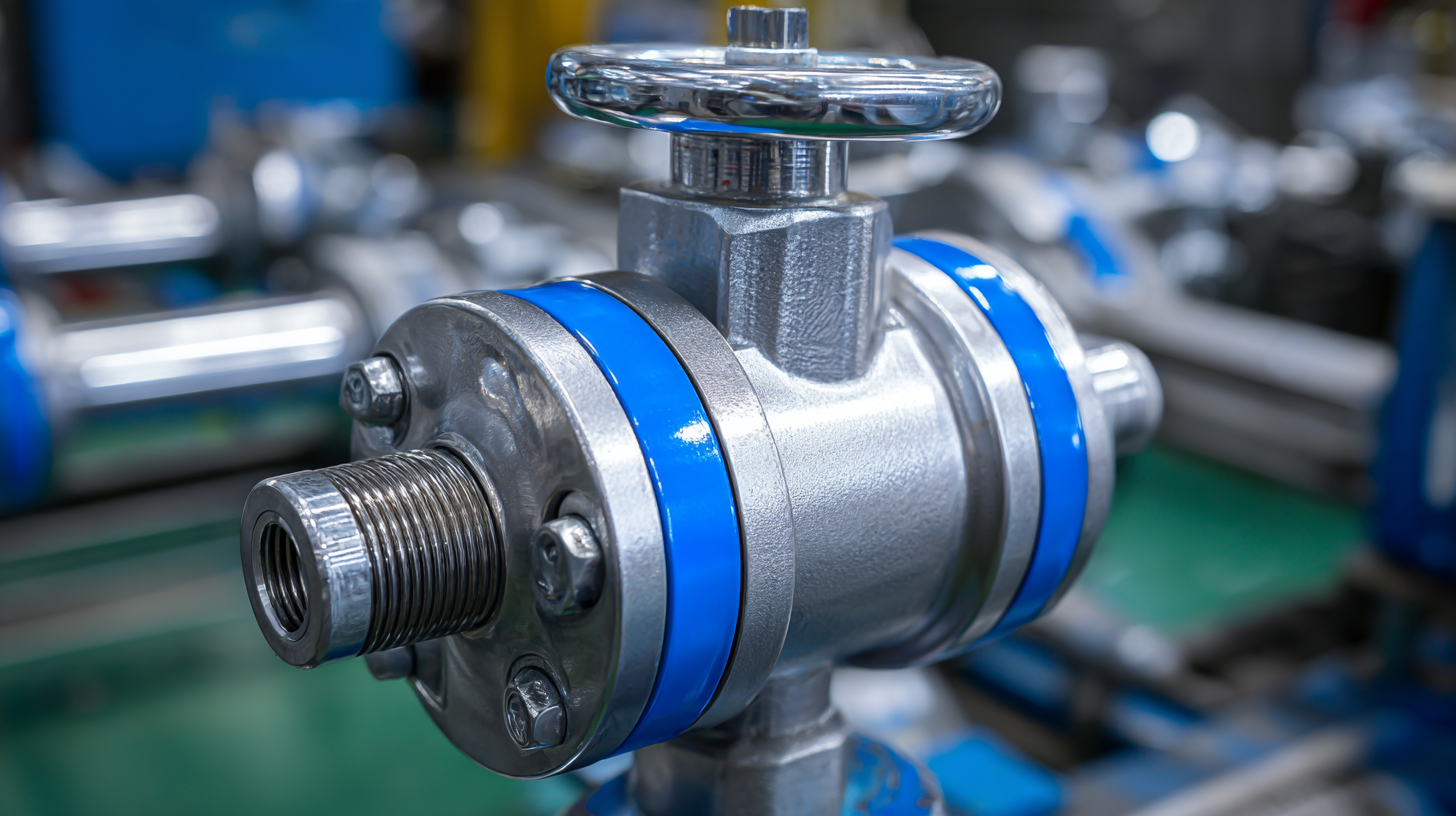

Pneumatic operated ball valves are increasingly favored in industrial settings due to their unique advantages that enhance operational efficiency and safety. One of the primary benefits of these valves is their rapid response time, which is crucial in applications requiring quick adjustments to pressure or flow. The Industrial Valve Market is projected to experience significant growth, driven by the increasing demand for automation in manufacturing processes. Reports indicate that the market size across various valve types, including ball valves, is set to expand significantly as industries prioritize efficiency and reliability.

Additionally, pneumatic ball valves offer excellent control capabilities and can be easily integrated with automation systems. Their ability to operate under a wide range of temperatures and pressures makes them suitable for diverse applications, from oil and gas to chemical processing. Industry analyses reveal that the ball valve segment, specifically, is witnessing growth trends owing to its favorable performance characteristics and reliability. The lower maintenance needs associated with pneumatic systems also contribute to reduced downtime, making them an economically viable choice for industrial operators.

Additionally, pneumatic ball valves offer excellent control capabilities and can be easily integrated with automation systems. Their ability to operate under a wide range of temperatures and pressures makes them suitable for diverse applications, from oil and gas to chemical processing. Industry analyses reveal that the ball valve segment, specifically, is witnessing growth trends owing to its favorable performance characteristics and reliability. The lower maintenance needs associated with pneumatic systems also contribute to reduced downtime, making them an economically viable choice for industrial operators.

Pneumatic operated ball valves are increasingly favored in industrial applications due to their responsiveness and efficiency. Unlike electric ball valves, which can experience delays due to the time it takes for electric motors to actuate, pneumatic valves offer rapid actuation and precise control. This swift operation not only enhances system efficiency but also minimizes the risk of downtime, making them ideal for applications that require quick response times.

Tips: When selecting between pneumatic and electric ball valves, consider the specific requirements of your application, including response time, operating environment, and maintenance needs. Pneumatic valves tend to excel in environments with fluctuating temperatures and pressures, while electric valves may be more suitable for applications requiring precise positioning and control.

Furthermore, the current growth trends in the control valve market highlight the increasing adoption of pneumatic actuation systems over electric counterparts due to their reliability and robustness. With the industrial valve market projected to grow significantly, businesses are encouraged to evaluate the benefits of incorporating pneumatic operated ball valves to enhance operational efficiency and reduce long-term costs.

| Feature | Pneumatic Ball Valves | Electric Ball Valves |

|---|---|---|

| Operating Speed | Fast Response Time | Moderate Response Time |

| Control Precision | High Control Precision | Moderate Control Precision |

| Power Consumption | Lower Power Consumption | Higher Power Consumption |

| Maintenance Requirements | Low Maintenance | Moderate Maintenance |

| Installation Complexity | Simple Installation | Complex Installation |

| Durability | High Durability | Moderate Durability |

| Sensitivity to Environment | Less Sensitive | More Sensitive |

When considering the installation of pneumatic operated ball valves in industrial applications, several key factors must be taken into account to maximize efficiency and performance. Pneumatic valves are known for their rapid actuation and precise control, making them ideal for environments where quick response times are critical. It is essential to assess the appropriate size and type of valve for the specific application, as improper selection can lead to operational inefficiencies or even system failures.

When considering the installation of pneumatic operated ball valves in industrial applications, several key factors must be taken into account to maximize efficiency and performance. Pneumatic valves are known for their rapid actuation and precise control, making them ideal for environments where quick response times are critical. It is essential to assess the appropriate size and type of valve for the specific application, as improper selection can lead to operational inefficiencies or even system failures.

Moreover, with the anticipated growth of the valves in the mining sector—projected to increase by $1.56 billion from 2025 to 2029—driven largely by advancements in smart mining technology, the relevance of robust installation practices becomes even more pronounced. Proper installation not only ensures optimal functionality but also enhances reliability, particularly in challenging conditions such as those presented in slurry pipelines. This highlights the importance of utilizing appropriately designed actuators, which can greatly affect the overall performance of pneumatic operated ball valves.

Choosing the right actuator and following best practices during the installation process are crucial steps in leveraging the advantages of these high-performing valves in industrial settings.

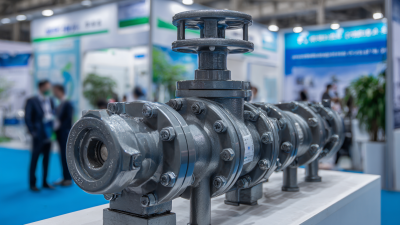

Pneumatic operated ball valves have become integral in various industrial applications, especially due to their quick action and reliability. According to a report from MarketsandMarkets, the global market for pneumatic valves is projected to reach USD 2.36 billion by 2025, with significant adoption in sectors such as oil and gas, water treatment, and food and beverage. These valves are particularly favored for their ability to achieve tight sealing and minimal leakage, which are crucial in environments where pressure management is vital.

In the oil and gas industry, pneumatic ball valves are commonly employed for their excellent handling of high-pressure applications. A study by Research and Markets highlighted that the oil and gas segment accounted for nearly 37% of the overall pneumatic valve market in 2020. The fast operation of pneumatic valves ensures efficient flow control during critical processes such as refining and distribution. Similarly, in water treatment facilities, these valves assist in regulating water flow, enabling operators to maintain consistent pressure and protect infrastructure through automation, ultimately enhancing operational efficiency. As industries continue to adopt automation technologies, the reliance on pneumatic operated ball valves is expected to grow, driving innovation and improving performance across multiple sectors.

This chart illustrates the common applications of pneumatic operated ball valves across various industries, highlighting their importance in chemical processing, oil and gas, water treatment, food and beverage, and pharmaceutical industries.