-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the world of industrial applications, the Carbon Steel Ball Valve stands out for its durability and reliability. Choosing the right valve can significantly impact your operations. This guide explores the top Carbon Steel Ball Valves of 2026. It will help you navigate features, benefits, and drawbacks.

Carbon Steel Ball Valves offer immense strength, making them ideal for high-pressure environments. However, they are not without their challenges. Some users report difficulty in installation and maintenance. It's essential to weigh these factors carefully.

This review aims to provide you with valuable insights. We will break down what to consider when purchasing a Carbon Steel Ball Valve. Whether you are a seasoned professional or a newcomer, our guide will equip you with the knowledge needed for informed decisions.

Carbon steel ball valves are vital components in various industries. They offer excellent durability and strength. This makes them suitable for high-pressure applications. Commonly used in oil, gas, and water systems, these valves control flow effectively. Their ability to seal tightly ensures minimal leakage. This characteristic is essential for both safety and efficiency.

When choosing a carbon steel ball valve, consider the working environment. Different designs cater to various temperatures and pressures. Pay attention to the valve's size as well. It needs to match your piping system. This can prevent unexpected problems. Also, ensure that the valve meets the necessary specifications. This can be a confusing process and worth reevaluating.

Tips: Always check for corrosion resistance. Carbon steel can rust, so a protective coating is helpful. Regular maintenance checks can prolong the valve's lifespan. Don’t overlook the importance of proper installation. A small mistake can lead to significant issues later on.

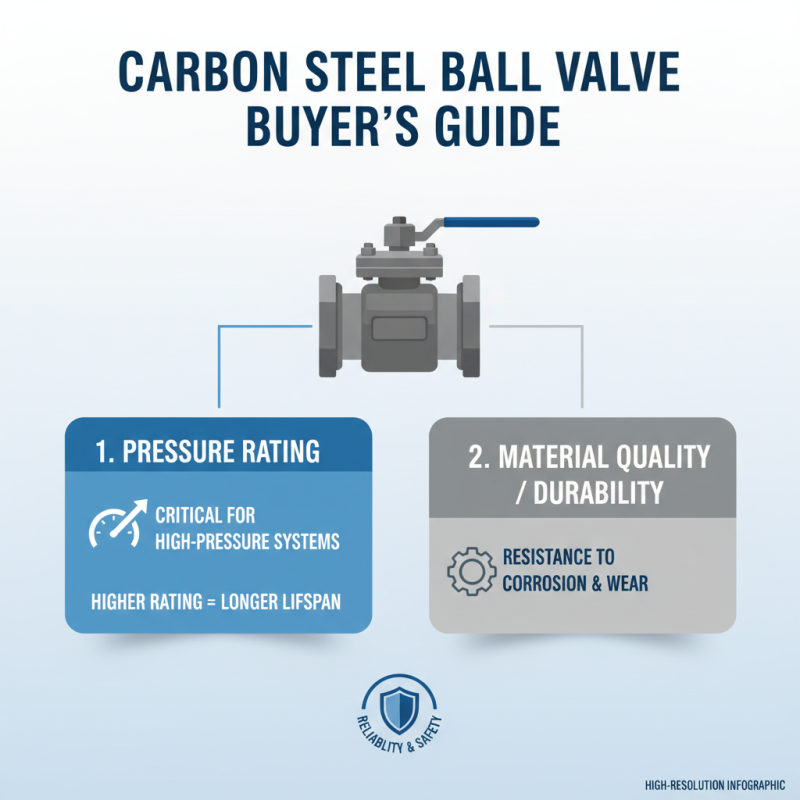

When choosing a carbon steel ball valve, several key features stand out. First, consider the valve's body material and construction. Durable carbon steel offers excellent pressure resistance. Look for a robust design that can handle various fluid types. Weight and portability also matter, especially for installation.

Another aspect is the valve's sealing mechanism. A reliable seal is crucial for preventing leaks. Examine the seat material and the quality of the O-ring for longevity. Valves with multiple sealing points usually provide better performance under pressure. Size and compatibility with existing piping systems are also essential for effective installation.

Don’t overlook the finish and coating on the valve. A protective layer can enhance corrosion resistance. It is worth noting that not all coatings are created equal, making it vital to do some homework. A poorly coated valve can result in premature failure. Always weigh each feature carefully to avoid costly mistakes down the line.

| Model | Size | Pressure Rating | Temperature Range | Connection Type | Weight |

|---|---|---|---|---|---|

| Model A | 1 inch | 600 PSI | -20°F to 250°F | Threaded | 5.5 lbs |

| Model B | 2 inch | 300 PSI | -30°F to 200°F | Welded | 9.0 lbs |

| Model C | 3 inch | 150 PSI | -40°F to 300°F | Flanged | 12.5 lbs |

| Model D | 4 inch | 600 PSI | -20°F to 400°F | Threaded | 15.0 lbs |

When selecting a carbon steel ball valve, consider key features that affect performance. Look for options with a durable construction. A good valve should resist corrosion and wear. Pay attention to the sealing mechanism. Well-designed seals ensure minimal leakage. Testing different models is recommended; not all claim the same quality.

The top five carbon steel ball valves of 2026 stand out for their efficiency and reliability. They have unique design features that enhance performance in various applications. Each valve offers varying flow rates and operating pressures. It's crucial to evaluate how each fits into your specific system.

Tips: Don’t rush your decision. Analyze your needs carefully. Even small differences in specifications can impact your operation. Test valves under real-world conditions if possible. A solid choice today can save time and money later.

Maintaining carbon steel ball valves is crucial for durability. Regular inspection helps catch issues early. Look for signs of wear, leakage, or rust. A small amount of rust can escalate into a bigger problem if not addressed.

Clean the valves regularly. Use a soft cloth and suitable detergent. Avoid abrasive materials that can scratch the surface. After cleaning, check for loose fittings. Tighten any that are not secure.

Lubrication is another important tip. Use a suitable grease for carbon steel. Apply it to the stem and the ball. Not too much; just enough to keep everything moving smoothly. It can prevent sticking. Remember, neglect can lead to costly repairs. Stay proactive to avoid the frustration of unexpected failures.

When purchasing a carbon steel ball valve, several factors come into play. First, consider the valve's pressure rating. This rating indicates how much pressure the valve can withstand. According to industry reports, valves with higher pressure ratings often have longer lifespans. This is critical in high-pressure systems where failure is not an option.

Another vital element is the connection type. Carbon steel valves often come with flanged or threaded connections. Each type has its own installation considerations. Flanged connections can handle higher forces but may require special gaskets. Keep in mind, the wrong connection choice can lead to leaks or malfunctions.

Additionally, the working temperature affects the valve's performance. Carbon steel can endure various temperatures but may degrade under extreme conditions. Reports suggest that temperatures exceeding 500°F can weaken the material. Always check temperature ratings before selecting.

Consider these factors carefully. It’s easy to overlook a small detail, like the connection type. Such oversights can lead to significant issues later on. Proper research and planning are essential for a successful purchase.