-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

As we look ahead to 2025, the landscape of the ball valves industry is poised for significant transformation driven by innovative technologies and evolving applications. According to a recent market analysis by the International Valve Manufacturers Association (IVMA), the global ball valve market is projected to reach $16 billion by 2025, growing at a CAGR of approximately 5.8%. This growth is fueled by increasing demands in sectors such as oil and gas, water and wastewater treatment, and power generation, where efficiency and reliability are paramount.

Industry expert Dr. Emily Johnson, a renowned authority on fluid control technologies, emphasizes the importance of innovation in this sector, stating, "The future of ball valves will be defined by smarter designs and advanced materials that enhance performance while reducing environmental impact." The push towards sustainability and the integration of IoT technologies are encouraging manufacturers to explore novel materials and automation solutions that improve operational efficiency and scalability.

In this evolving landscape, understanding the top trends in ball valves innovations and their applications will be critical for stakeholders aiming to harness these advancements. From the adoption of smart valve technologies to the implementation of eco-friendly materials, the next few years will see pivotal changes that will shape the future performance and functionality of ball valves across various industries.

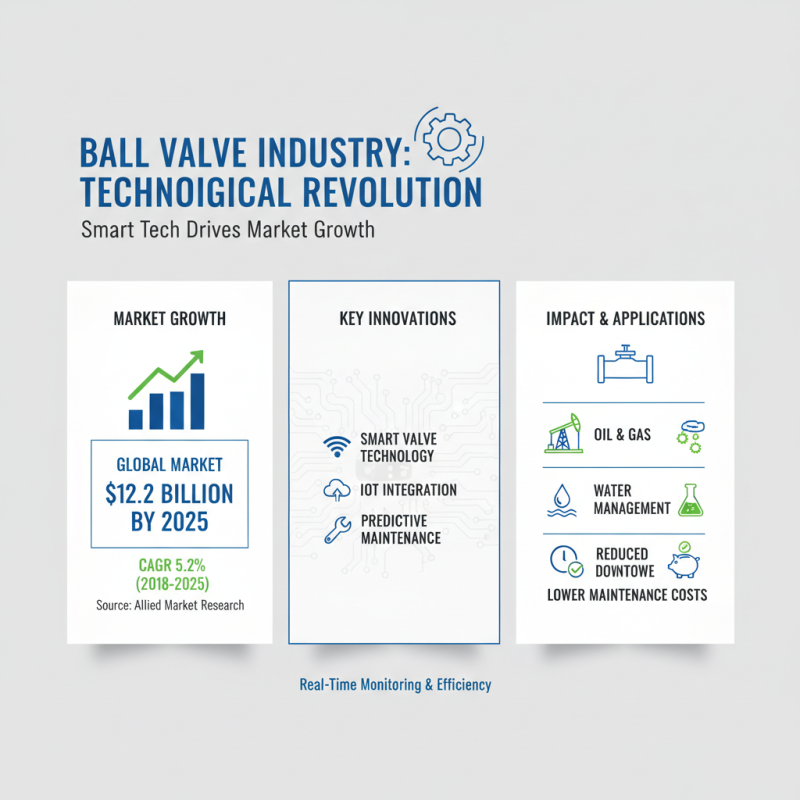

The ball valve industry is witnessing significant technological advancements that are set to redefine its applications across various sectors. According to a recent report by Allied Market Research, the global ball valve market is projected to reach $12.2 billion by 2025, growing at a CAGR of 5.2% from 2018 to 2025. This growth is propelled by innovations in smart valve technology, where digital communication and IoT integration enhance operational efficiency and predictive maintenance. These innovations enable real-time monitoring of valve performance, reducing downtime andmaintenance costs in industries such as oil and gas, water management, and chemical processing.

In addition to smart technology, advancements in materials science are revolutionizing ball valve design. The introduction of lightweight, corrosion-resistant materials like PVD coatings and advanced polymers allows for increased durability and reduced maintenance requirements. A report by Grand View Research indicates that the demand for sophisticated materials in valve manufacturing is projected to increase, driven by the need for valves that can withstand extreme conditions while maintaining operational integrity. Thus, as the industry leans toward automation and efficiency, these emerging trends illustrate a shift towards more advanced, reliable, and cost-effective solutions in ball valve applications.

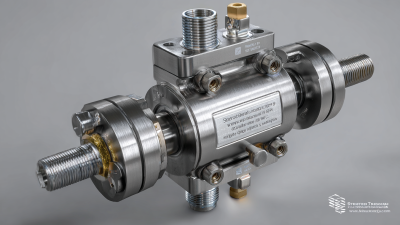

The integration of smart technologies in ball valve applications marks a significant advancement in industrial automation and control systems. This convergence allows for enhanced monitoring and operational efficiency, catering to the growing demand for intelligent solutions in various sectors, including oil and gas, water treatment, and food processing.

Smart ball valves equipped with sensors and IoT capabilities enable real-time data collection, offering insights into flow rates, pressure levels, and valve performance. This information not only aids in predictive maintenance but also enhances decision-making processes, optimizing workflow and reducing downtime.

Moreover, the implementation of artificial intelligence and machine learning algorithms further elevates the functionality of ball valves. These technologies can analyze historical performance data to predict potential failures and suggest maintenance schedules, thereby decreasing operational costs. Enhanced automation features allow operators to remotely control and adjust valve settings through smart interfaces, providing greater flexibility and safety in managing complex systems. As industries strive for sustainability and efficiency, the integration of smart technologies in ball valves represents a crucial step towards achieving smarter and more resilient infrastructures.

The ball valve industry is experiencing a significant transformation as sustainability becomes a fundamental aspect of manufacturing and material selection. According to a recent report by Global Industry Analysts, the market for environmentally friendly valve solutions is projected to reach $5 billion by 2025, driven by increased regulatory pressures and a growing emphasis on reducing carbon footprints. This shift highlights the industry's commitment to incorporating recycled materials and sustainable manufacturing practices to minimize environmental impact. Manufacturers are increasingly adopting advanced techniques such as additive manufacturing, which not only reduces waste but also enhances the performance and durability of ball valves.

Furthermore, the trend towards sustainable materials is prominently featured in the development of high-performance polymers and composite materials. The latest studies indicate that using materials like PVDF and PEEK can enhance the lifespan of ball valves while ensuring compliance with stringent environmental regulations. Specifically, these materials are noted for their chemical resistance and low environmental toxicity, which align with global sustainability goals. As the industry moves forward, the integration of circular economy principles—recycling, reusing, and reducing material waste—will play a pivotal role in shaping future innovations in ball valve applications across various sectors, including water treatment, oil and gas, and renewable energy.

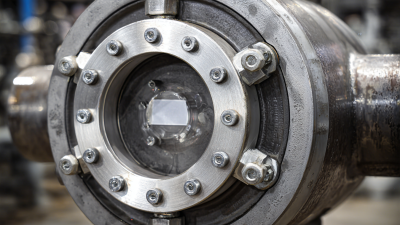

The evolution of ball valves is heavily influenced by enhanced performance metrics and rigorous testing standards that ensure reliability and efficiency across various applications. As industries continue to push for greater efficiency, manufacturers are focusing on developing ball valves that can withstand extreme conditions while delivering high levels of performance. Enhanced performance metrics now include parameters such as torque-to-open ratios, sealing integrity under high pressure, and resistance to temperature fluctuations. These advancements are crucial for sectors like oil and gas, water management, and chemical processing, where even minor failures can lead to significant operational disruptions.

Moreover, the establishment of standardized testing protocols has become vital in assessing the performance of ball valves. Organizations are now advocating for comprehensive testing regimes that encompass both static and dynamic testing scenarios to evaluate durability, leak-tightness, and operational life. These standards ensure that all products meet industry requirements and can reliably perform over extended periods. By adhering to stringent testing guidelines, manufacturers can not only enhance the credibility of their products but also foster greater confidence among users. As innovations continue to emerge, the synergy between advanced performance metrics and robust testing standards will define the future of ball valve applications.

| Trend | Description | Enhanced Performance Metric | Testing Standard |

|---|---|---|---|

| Smart Ball Valves | Integration of IoT for real-time monitoring and control. | Real-time flow and pressure data accuracy | ASME B16.34 |

| High-Pressure Ball Valves | Valves designed for extreme pressure applications. | Maximum pressure rating increase from 5000 psi to 10000 psi | API 6D |

| Bi-directional Flow Ball Valves | Valves capable of controlling flow in both directions. | Improved flow control efficiency by 15% | ISO 17292 |

| Corrosion-Resistant Materials | Use of advanced composites and coatings. | Lifecycle cost reduction by 20% due to improved durability | ASTM B117 |

| Automation of Ball Valves | Increased automation in industrial processes. | Reduction in manual intervention by 50% | IEC 61508 |

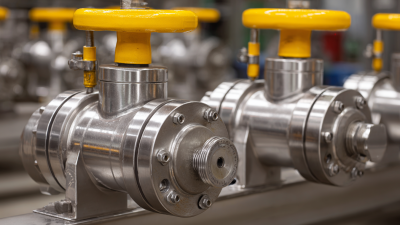

The ball valve market is anticipated to witness significant growth in the coming years, driven by increasing demand across various sectors. According to a report by MarketsandMarkets, the global ball valve market is projected to reach approximately $14 billion by 2025, growing at a compound annual growth rate (CAGR) of around 5.4% from 2020 to 2025. This increase can be attributed to the expanding oil and gas sector, where ball valves play a crucial role in controlling the flow of liquids and gases, as well as in the petrochemical and water treatment industries.

Emerging trends in ball valve innovations, such as the integration of IoT technology and advancements in materials, are also shaping the market landscape. The implementation of smart valves that can communicate data in real-time is creating substantial demand within industrial applications. As per a report by ResearchAndMarkets, the adoption of smart technology in valve systems is expected to grow significantly, reflecting an increasing focus on automation and predictive maintenance. Additionally, eco-friendly materials used in manufacturing ball valves are gaining traction, aligning with the global push for sustainability. This trend is evident as industries prioritize reduced environmental impact while maintaining operational efficiency.