-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the realm of industrial applications, the importance of understanding production standards for various equipment cannot be overstated, especially when it comes to

Wafer Ball Valves. These compact yet efficient valves play a crucial role in fluid control across a wide array of settings.

However, despite their growing popularity, users often encounter significant challenges associated with different types of Wafer Ball Valves.

Factors such as material quality, design specifications, and operational compatibility frequently lead to performance issues, ultimately affecting system efficiency.

This blog aims to delve into the common problems associated with different Wafer Ball Valve types and their production standards,

providing insights into how to navigate these complexities for optimal performance and reliability in industrial applications.

In the realm of industrial applications, the importance of understanding production standards for various equipment cannot be overstated, especially when it comes to

Wafer Ball Valves. These compact yet efficient valves play a crucial role in fluid control across a wide array of settings.

However, despite their growing popularity, users often encounter significant challenges associated with different types of Wafer Ball Valves.

Factors such as material quality, design specifications, and operational compatibility frequently lead to performance issues, ultimately affecting system efficiency.

This blog aims to delve into the common problems associated with different Wafer Ball Valve types and their production standards,

providing insights into how to navigate these complexities for optimal performance and reliability in industrial applications.

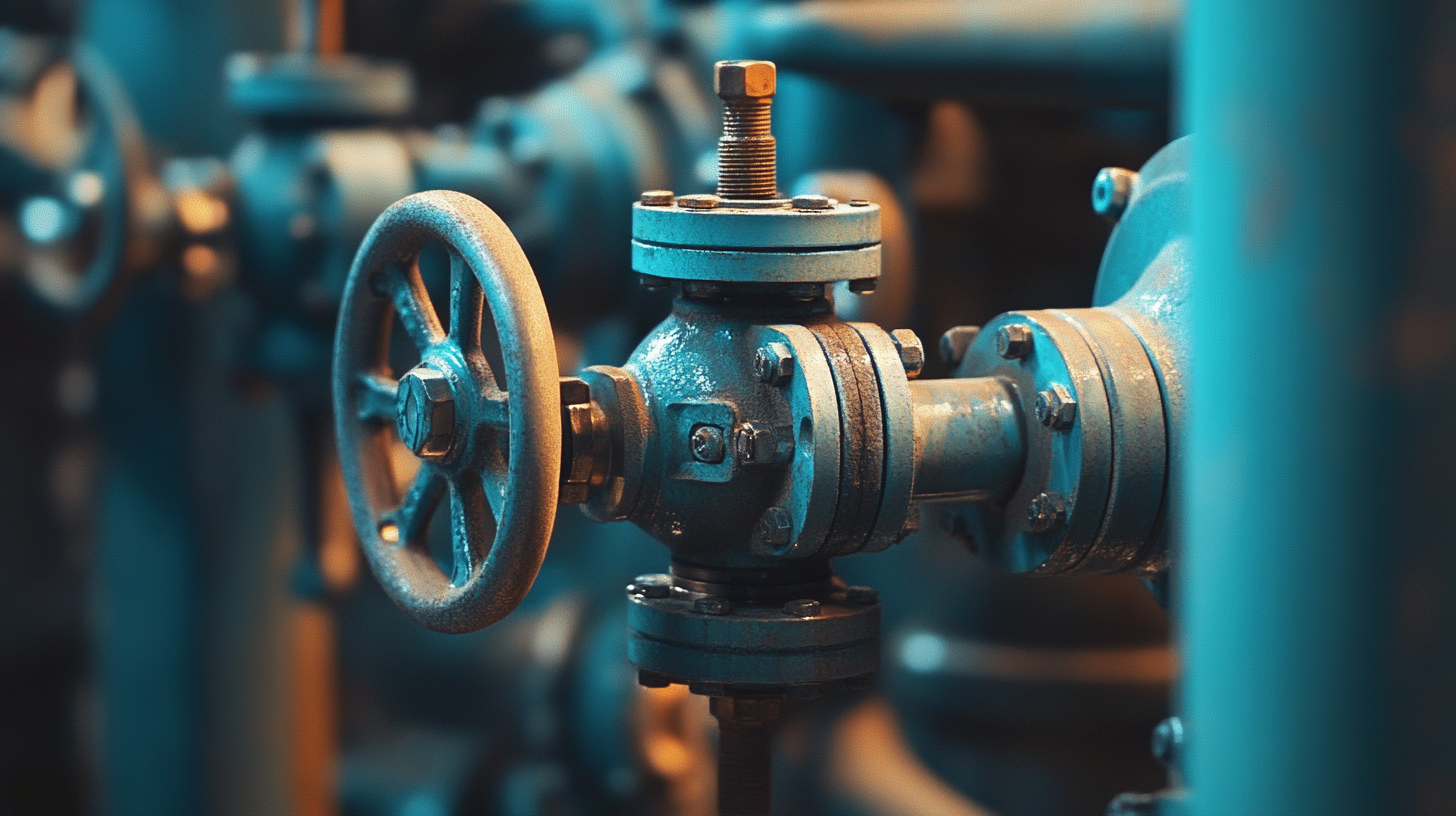

Wafer ball valves are a crucial component in various industrial applications, characterized by their compact design and ease of installation. Unlike traditional flanged valves, wafer ball valves fit between two flanges, reducing the overall footprint. This makes them ideal for applications where space is limited, such as HVAC systems, water treatment plants, and chemical processing facilities. Their lightweight structure allows for quick installation and maintenance, making them a popular choice among engineers and contractors.

Different types of wafer ball valves cater to diverse needs within the industry. For instance, the standard wafer ball valve is typically used in on-off services, providing a reliable sealing mechanism. In contrast, high-performance wafer ball valves are designed for more demanding applications, where constant pressure and temperature fluctuations are expected. Additionally, there are specialized valves, such as those with anti-static features or built from corrosion-resistant materials, suitable for handling hazardous chemicals. Understanding the various types and their specific applications is essential for selecting the right wafer ball valve to ensure optimal performance and longevity in any system.

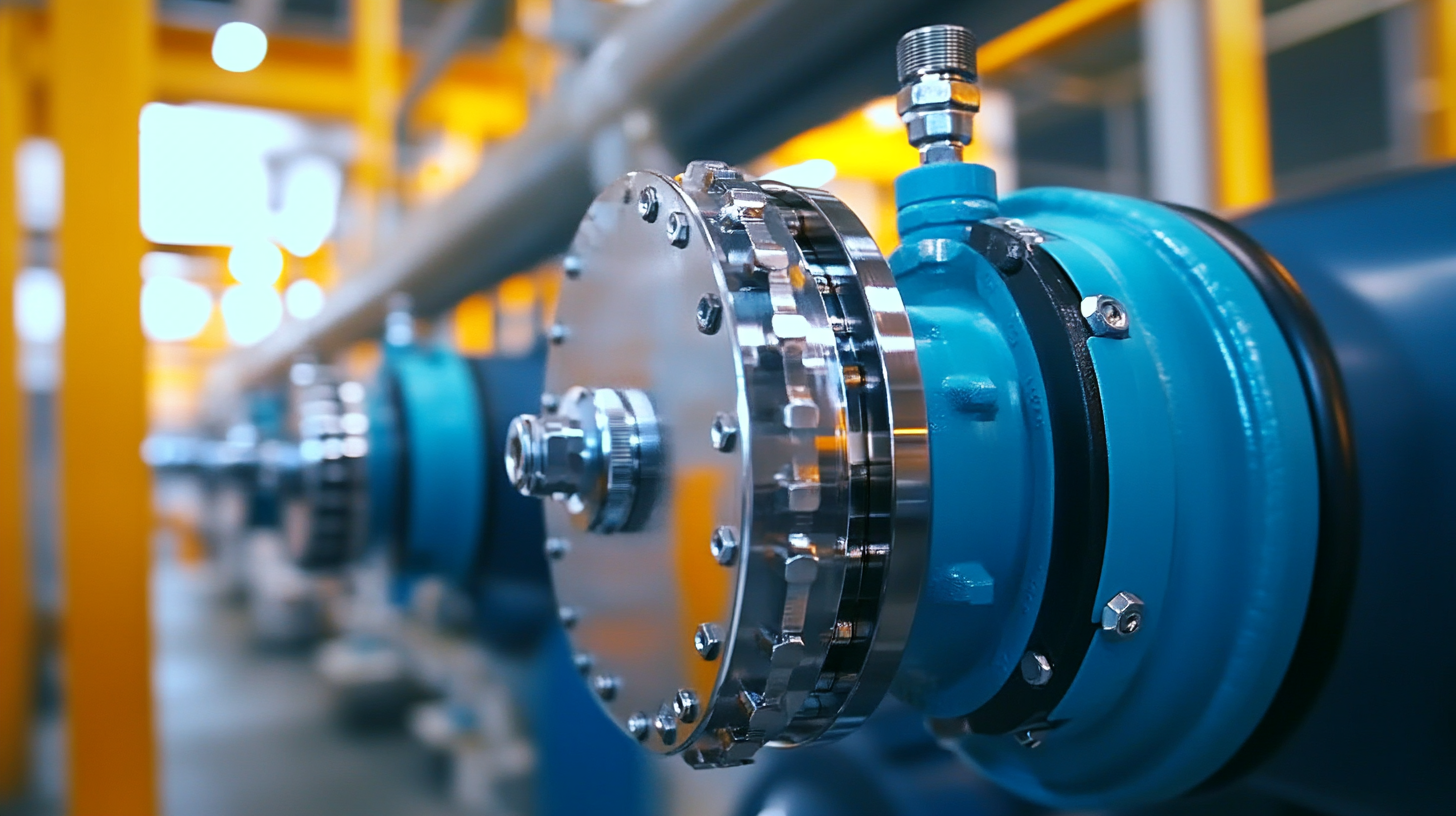

When selecting wafer ball valves for industrial applications, understanding the key technical specifications is crucial.

One of the fundamental factors to consider is the valve material. Common materials include stainless steel, carbon steel, and PVC, each offering different levels of corrosion resistance and durability.

Stainless steel, for instance, is ideal for harsh environments due to its resistance to oxidation and rust, while PVC is more suited for lightweight and chemical-resistant applications.

The choice of material directly affects the valve's longevity and reliability in service.

Another vital specification is the pressure rating of the wafer ball valve. It is essential to match the valve's pressure rating with the system's operating pressure to ensure safety and functionality.

Most wafer ball valves are standardized to meet specific pressure classes, such as ANSI or DIN ratings.

Additionally, the valve size and the end connections determine how it integrates within existing piping systems. Proper sizing ensures optimal flow characteristics and minimizes turbulence.

Understanding these technical specifications helps engineers make informed decisions that enhance system performance and compliance with industry standards.

When exploring the best wafer ball valve brands, it’s essential to conduct a comparative analysis across a range of parameters, including material quality, durability, and flow efficiency. Brands like Apollo and Olet each have unique offerings that cater to different requirements across industries.

Apollo is renowned for its robust construction, often made from high-grade stainless steel, ensuring longevity in high-pressure environments. In contrast, Olet balances performance with affordability, making it a popular choice for budget-conscious projects without compromising significant quality.

Another vital aspect to consider is the technological advancements that each brand incorporates into its designs. For instance, brands such as Valworx emphasize user-friendly features with options for automation integration, enhancing operational efficiency.

Additionally, some manufacturers, like KITZ, pride themselves on their innovative sealing technologies, which minimize leaks and maximize reliability. By assessing these factors, buyers can make informed decisions that align with their specific application needs, ensuring optimal performance and value in their operations.

When it comes to installing and maintaining wafer ball valves, understanding the specific requirements and best practices is essential for ensuring optimal performance and longevity. Wafer ball valves require precise alignment and sealing during installation to prevent leaks and ensure effective flow control. It's crucial to use the right tools and techniques to secure the valve between flanges, ensuring that the sealing gaskets are properly positioned. Regular inspection of these components can prevent future operational issues.

Maintenance of wafer ball valves involves periodic checks for signs of wear or damage. This includes inspecting the valve for leaks, ensuring the ball and seat are clean and free from debris, and lubricating moving parts where necessary. Just like maintaining other critical equipment, such as cars and refrigeration systems, a proactive approach to valve maintenance can significantly enhance operational efficiency. Proper care and attention to detail not only extend the life of the valves but also contribute to overall system reliability and safety.

This chart illustrates the production standards of wafer ball valves across various criteria. The data reflects the quality and performance requirements essential for optimal valve functionality in industrial applications.

In the production of wafer ball valves, adhering to established industry standards is crucial for ensuring the quality, safety, and reliability of the end product. These standards typically encompass material specifications, design criteria, testing methodologies, and performance benchmarks that manufacturers must follow. For example, the American National Standards Institute (ANSI) provides guidelines for the design and construction of valves, while the International Organization for Standardization (ISO) offers internationally recognized standards that address various aspects of valve performance. Compliance with these standards not only enhances product consistency but also reduces the risk of failures in critical applications.

In the production of wafer ball valves, adhering to established industry standards is crucial for ensuring the quality, safety, and reliability of the end product. These standards typically encompass material specifications, design criteria, testing methodologies, and performance benchmarks that manufacturers must follow. For example, the American National Standards Institute (ANSI) provides guidelines for the design and construction of valves, while the International Organization for Standardization (ISO) offers internationally recognized standards that address various aspects of valve performance. Compliance with these standards not only enhances product consistency but also reduces the risk of failures in critical applications.

Additionally, industry standards such as the American Society of Mechanical Engineers (ASME) codes and the British Standards Institution (BSI) specifications play an important role in wafer ball valve production. These standards help ensure that the valves can withstand specific pressures, temperatures, and other operating conditions, ultimately leading to safer and more efficient systems. Manufacturers might also implement rigorous testing protocols to validate the operational efficacy of their valves against these standards, ensuring that they meet or exceed the expected performance criteria. By prioritizing adherence to these regulations, manufacturers can bolster their reputation and market competitiveness in the valve industry.