-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the world of fluid control systems, Floating Ball Valves play a crucial role. These valves have gained significant popularity due to their reliability and performance. According to a recent report by Global Market Insights, the floating ball valve market is expected to reach $5 billion by 2026, driven by increasing demand in various industries.

Expert David Thompson notes, "Floating ball valves provide excellent sealing capabilities, making them ideal for critical applications." His insights highlight the valves' importance in maintaining system efficiency. However, some companies still overlook their need for regular maintenance. Neglecting this can lead to efficiency losses and potential system failures.

As we approach 2026, innovation in floating ball valves is essential. The industry must focus on developing more resilient materials and designs. These improvements will address existing challenges. Investing in high-quality floating ball valves can ensure optimal performance in fluid control systems.

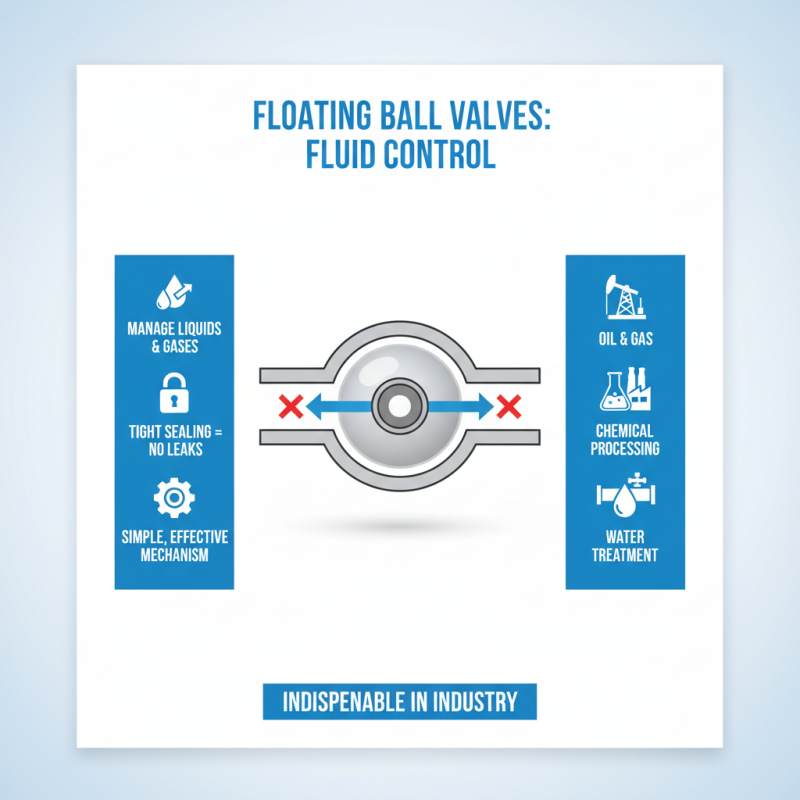

Floating ball valves play a crucial role in fluid control systems. They are designed to manage the flow of liquids and gases efficiently. Their simple yet effective mechanism allows for tight sealing when closed. This helps prevent leaks, which is essential in many applications. In various industries like oil and gas, chemical processing, and water treatment, these valves are indispensable.

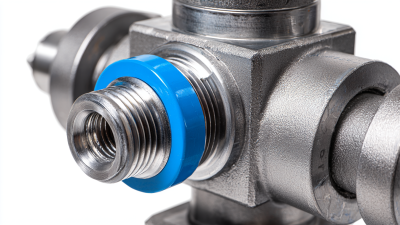

Tips: Always ensure a proper fit during installation. A misaligned valve can lead to significant issues. Regular maintenance checks are vital for long-term performance.

These valves excel in on-off applications. However, they may not be suitable for throttling. Operators need to understand the specific demands of their system. A floating ball valve can malfunction if used incorrectly. In some cases, the ball may stick due to debris. Keeping the working environment clean is crucial for optimal function.

Tips: Use filters to reduce fluid contaminants. This simple addition can extend valve life. Also, consider the temperature and pressure ratings of the valve. Operating outside these limits can lead to failure.

Floating ball valves are essential in fluid control systems. They provide various advantages that make them popular in many industries. One key feature is their simplicity. The design uses a floating ball that seals against the valve seat when closed. This straightforward mechanism reduces the risk of leaks.

Another notable benefit is their versatility. Floating ball valves can handle a wide range of fluids, including water, oil, and gas. Their robust construction allows them to operate effectively under varying pressures and temperatures. Additionally, they are easy to maintain, leading to reduced downtime. However, regular maintenance is still crucial. Neglecting it can result in performance issues and costly repairs.

In many cases, users must ensure the correct size and type of valve. Selecting an inappropriate valve could cause inefficiencies. It is important to reflect on the system requirements before making decisions. This careful consideration can enhance overall performance and reliability in fluid control applications.

Floating ball valves are essential in fluid control systems. They provide a reliable means of regulating flow. In 2026, several manufacturers stand out for their innovative designs. These valves are renowned for ease of operation. They can handle various fluid types, including water, oil, and gases.

Manufacturers focus on durability and efficiency. They use high-quality materials that resist wear. Some are experimenting with ceramic coatings for better longevity. However, achieving perfect sealing remains a challenge. Users often report issues with leaks over time.

Moreover, maintenance is crucial for floating ball valves. Many operators overlook regular checks. This oversight can lead to system failures. Refining designs is necessary to address these problems. Continuous improvement is key. Manufacturers must listen to user feedback. This interaction could enhance product reliability.

Floating ball valves are essential in fluid control systems, offering reliability and efficiency. Recent data indicates that the global floating ball valve market is projected to grow at a CAGR of 6.5% from 2023 to 2028. This highlights an increasing demand, especially in industries like oil and gas. Key features, such as seal integrity and ease of maintenance, influence their adoption.

A comparative analysis reveals variations in design. Some valves utilize a two-piece body design, while others favor a three-piece configuration. Each design has advantages and drawbacks. For instance, a three-piece design allows for easier repairs but may exhibit slightly higher leak rates than two-piece designs. Notably, the choice of materials also plays a pivotal role. Valves made from stainless steel show better corrosion resistance but come at a higher cost.

Maintenance remains a challenge. Regular inspections are necessary to ensure optimal performance. Studies suggest that neglected maintenance can lead to a 30% reduction in valve lifespan. Furthermore, installation errors may compromise the effectiveness of even the most advanced designs. It is crucial for users to weigh these factors carefully when selecting floating ball valves for their fluid control applications.

The future of fluid control systems is dynamic. As demand grows for efficient flow management, the design of valves, especially floating ball valves, is evolving. Innovations aim to increase performance and reduce energy consumption. These valves provide excellent sealing capabilities. Their simplicity reduces maintenance needs, yet they can sometimes be over-engineered.

One emerging trend is the integration of smart technology. Sensors in valves enhance monitoring and control. This leads to improved data collection and analysis. Real-time information helps operators make better decisions. However, reliance on technology may introduce vulnerabilities. There's a fine line between innovation and complexity.

Sustainability is another key focus. Manufacturers seek materials that minimize environmental impact. The aim is to create durable products that last longer. However, finding the right balance between cost and sustainability can be challenging. As the industry addresses these issues, reevaluation and adaptation will become essential in fluid control systems.