-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

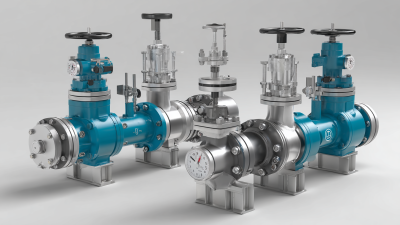

Flanged Ball Valves are crucial in many industries. Their ability to control flow efficiently makes them a top choice. With the right design, these valves offer optimal performance. However, not all options are created equal.

In this guide, we will explore the top 10 Flanged Ball Valves. Each valve will be analyzed for its unique features and performance metrics. Some may shine in certain applications while lacking in others. This highlights the need to choose wisely based on specific requirements.

Understanding the variety of Flanged Ball Valves is essential. Many factors influence their effectiveness. This includes material composition, size, and pressure tolerance. By reflecting on these aspects, you will make a more informed choice. It is not simply about picking the first available option. Instead, aim for a valve that truly meets your needs.

Flanged ball valves are critical components in many industrial applications. They offer reliable control of fluid flow with minimal pressure drop. These valves are designed with flanges that facilitate easy installation and maintenance. Proper selection can enhance system performance significantly.

Many industries rely on flanged ball valves for their durability and efficiency. Common applications include oil and gas, water treatment, and chemical processing. However, selecting the right valve requires careful consideration. Misjudgments can lead to leaks or inefficient flow control. Users must evaluate factors such as material compatibility or pressure ratings.

When dealing with flanged ball valves, attention to detail is essential. Not all valves will perform equally in different environments. The seal quality should be scrutinized. Small imperfections can lead to larger issues. Regular inspection and maintenance are equally important to ensure optimal functionality. It's an ongoing process that requires diligence and foresight.

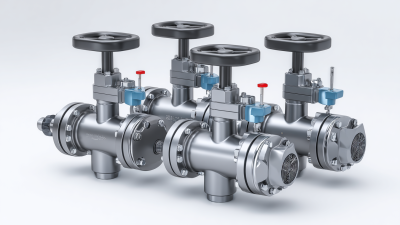

When selecting flanged ball valves, prioritize certain key features. One crucial aspect is the material of construction. High-quality valves often use robust materials that withstand corrosion. Stainless steel is a popular choice for its durability and resistance to harsh environments. Pay attention to the valve body design too. A streamlined design reduces pressure loss, which is vital for optimal performance.

Ensure the valve has a reliable sealing mechanism. This prevents leakage, enhancing safety and efficiency. Look for valves with strong seat materials, as these can improve longevity. Don’t forget about the valve size and compatibility with your piping system. Proper alignment is essential for smooth functionality.

**Tip:** Always consider the operating pressure and temperature range of your application. It is important to match the valve specifications to your needs for optimal results.

Another feature worth examining is ease of operation. A user-friendly handle or actuator can make a significant difference. Also, consider the maintenance requirements. Some valves may require more frequent inspections or replacements.

**Tip:** Regularly monitor your valve system's performance. Early detection of issues can save time and costs in the long run.

Flanged ball valves play a crucial role in fluid control systems across industries. Their design allows for a secure connection and reliable operation under high pressure. According to market research, the global flanged ball valve market was valued at approximately $2.5 billion in 2022, with an expected growth rate of 5% over the next five years. This growth reflects a rising demand for durable and efficient valve technologies.

Leading manufacturers focus on innovative materials and design features. High-performance ball valves often use stainless steel, ensuring resistance to corrosion and wear. Performance metrics indicate that flanged ball valves can operate effectively at temperatures exceeding 200°C. Despite this, not all products meet these standards consistently. Some models have reported sealing issues under specific conditions. Such details are vital when choosing the right valve manufacturer.

Expert reviews frequently highlight the importance of certification. Valves should adhere to industry standards like ISO or ANSI. Many suppliers claim compliance, but not all provide proof. Transparency in performance data remains essential for informed decisions. Overall, when selecting flanged ball valves, understanding brand reliability and product specifications is key.

When considering flanged ball valves, performance is key. These valves ensure reliable flow control. A variety of options exist, each with unique features. Some models stand out due to their durability. Others may excel in ease of installation. It's crucial to analyze these aspects carefully.

Material choice is essential. Stainless steel offers corrosion resistance, making it popular. However, for high-temperature applications, different materials may be better suited. Flanged ball valves also vary in size and pressure ratings. This will directly affect their applicability in various scenarios. Not all valves will perform well under extreme conditions.

Price can be a factor too. Investing in a slightly more expensive valve may yield better long-term performance. Cheaper options might require frequent replacements, which could lead to frustration. It’s essential to balance cost against performance needs while making a choice. Sometimes, what seems ideal at first may not fulfill expectations once installed. A thorough evaluation can prevent such outcomes.

| Valve Type | Material | Pressure Rating | Size Range (inches) | Temperature Range (°F) | Special Features |

|---|---|---|---|---|---|

| Floating Ball | Carbon Steel | 150 PSI | 2 to 8 | -20 to 300 | Fire Safe Design |

| Trunnion Mounted | Stainless Steel | 600 PSI | 4 to 12 | -40 to 450 | Low Torque Operation |

| Full Port | PVC | 150 PSI | 1 to 6 | -10 to 140 | Corrosion Resistant |

| Reduced Port | Bronze | 300 PSI | 1/2 to 3 | -20 to 200 | Compact Design |

| Electric Actuated | Stainless Steel | 300 PSI | 2 to 10 | -40 to 300 | Remote Control |

| Pneumatic Actuated | Carbon Steel | 150 PSI | 3 to 8 | -20 to 250 | Quick Response |

| Check Valve | Ductile Iron | 250 PSI | 2 to 6 | -20 to 300 | Self-Actuating |

| High Pressure | Alloy Steel | 1500 PSI | 2 to 6 | -40 to 500 | Heavy duty |

| Sanitary Ball Valve | 316 Stainless Steel | 150 PSI | 0.5 to 6 | -20 to 250 | Hygienic Design |

| Electric Floating Ball Valve | Polypropylene | 100 PSI | 1 to 4 | -10 to 150 | Compact Electric Actuator |

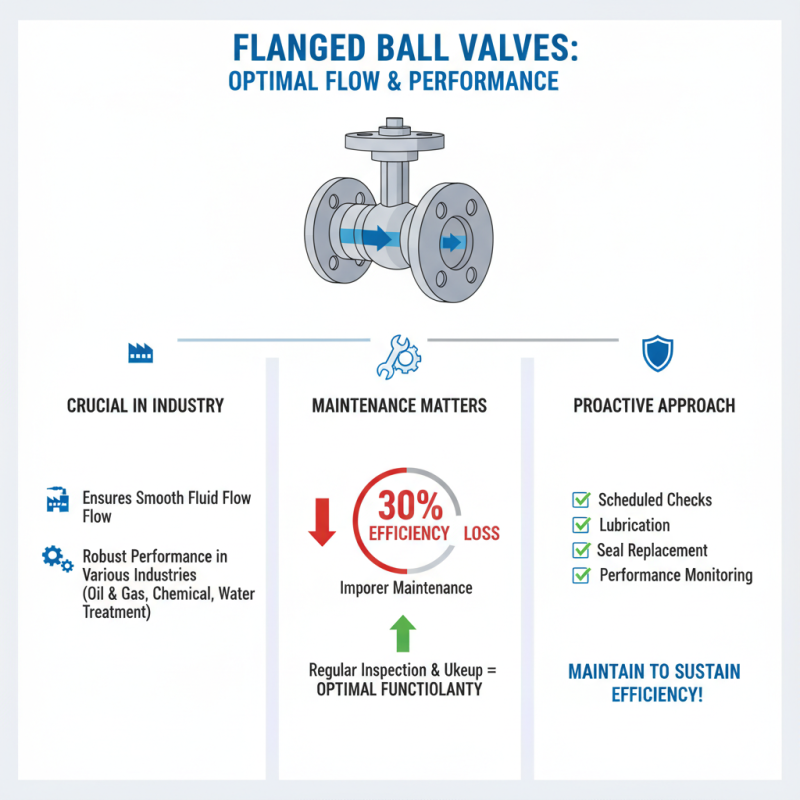

Flanged ball valves are crucial in various industries, ensuring smooth fluid flow and robust performance. To maintain optimal functionality, regular inspection and maintenance are imperative. Studies reveal that improper maintenance can lead to a 30% loss in efficiency. Thus, operators must adopt a proactive approach.

Routine inspection should include checking for leaks and corrosion. Any signs of wear can indicate potential failure points. According to industry reports, nearly 25% of valve failures stem from inadequate maintenance practices. Operators should also lubricate moving parts according to the manufacturer’s guidelines, which significantly enhances the valve's lifespan.

Another vital aspect is the calibration of flanged ball valves. Incorrect settings can disrupt flow and pressure. In fact, over 15% of systems experience issues due to misaligned valves. Operators should keep a maintenance log to document all adjustments. Reflecting on past maintenance can highlight areas for improvement and identify recurring problems. Regular training for maintenance personnel can lead to better outcomes, ensuring the long-term integrity of the valves.