-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

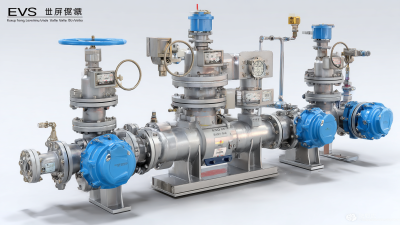

In the world of industrial valves, "Duplex Ball Valves" represent a vital innovation. As experts like John Smith, a leading engineer at Valve Innovations, state, "These valves combine strength with precision." This makes them essential in many applications.

Duplex Ball Valves are known for their unique durability. Made from high-performance materials, they withstand extreme conditions. They are not just strong; they are also versatile. Their design allows for easy maintenance, which is crucial for many industries.

However, not every Duplex Ball Valve is equal. Some have design flaws that can make them less effective. It's important to research and choose wisely. While these valves have numerous benefits, their complexities can be daunting. The right choice can enhance efficiency, but the wrong one can lead to headaches. Understanding these nuances is critical for success in choosing the perfect Duplex Ball Valve.

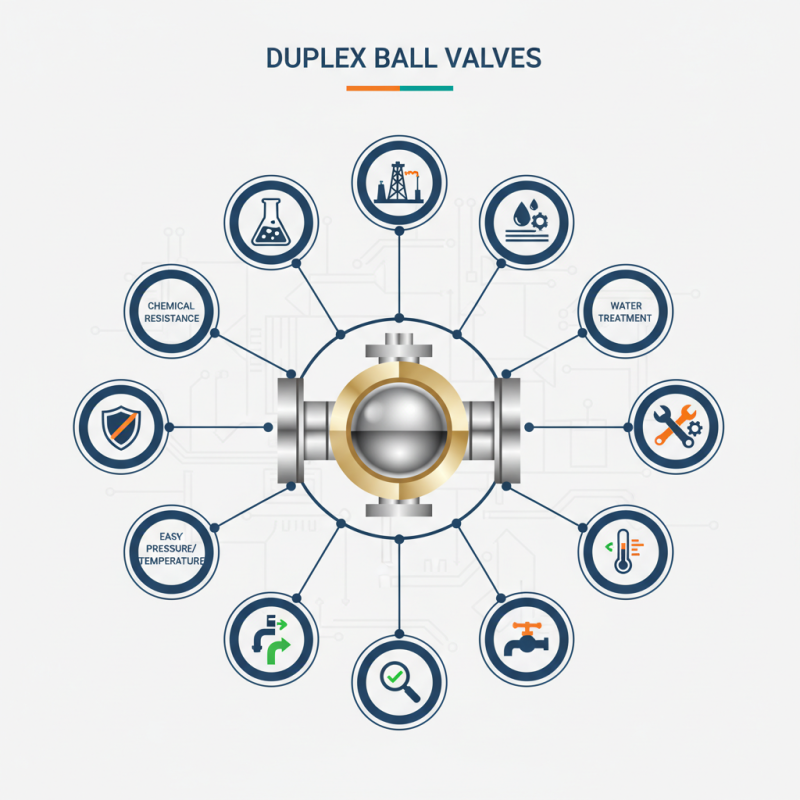

Duplex ball valves are essential components in many industries. They are designed to control fluid flow. Made from duplex stainless steel, these valves offer excellent corrosion resistance. This makes them ideal for harsh environments. Common applications include oil and gas, chemical processing, and marine industries. The ability to withstand high pressures and temperatures is crucial.

These valves have a unique structure that allows for quick operation. Their design often features two balls that can be engaged or disengaged. This provides seamless flow control and minimizes pressure loss. However, selecting the right duplex ball valve can be challenging. Different applications require specific features. For instance, a valve for a high-temperature application will differ from one meant for corrosive substances.

It's vital to understand the specific needs of your system. Some users might overlook details like compatibility with certain fluids. Incorrect choices can lead to failures. Regular maintenance is also important to ensure long-term functionality. Without it, even the best valves can fail under stress. Thus, when considering duplex ball valves, careful thought is required. Make sure to evaluate all aspects before making a decision.

This bar chart illustrates the pressure ratings of the top 10 duplex ball valves based on their sizes. Duplex ball valves are essential in various industrial applications due to their high resistance to corrosion and high pressure, making them ideal for demanding environments.

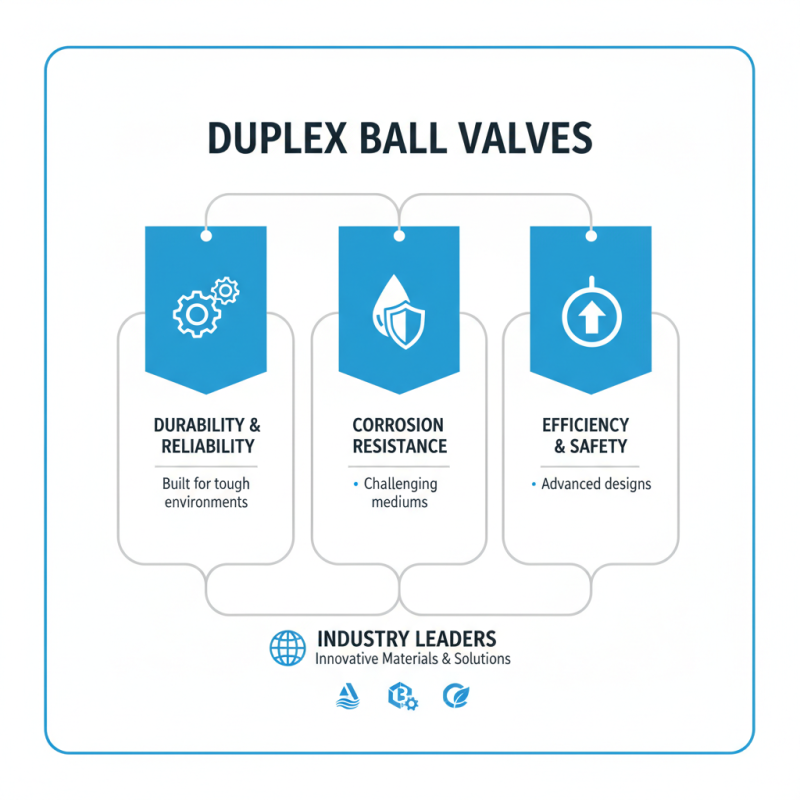

Duplex ball valves are essential in various industries. They offer durability, reliability, and resistance to corrosion. This makes them suitable for challenging environments. Key manufacturers lead the market by providing innovative solutions with advanced materials. Their designs often focus on maximizing efficiency and safety.

Some notable features include enhanced flow control and low maintenance requirements. Manufacturers prioritize quality and performance. However, not all products meet the highest standards. Buyers must carefully assess their options. Some offerings may lack the necessary certifications, raising concerns about safety.

Markets worldwide have seen growth in duplex ball valve usage. Many manufacturers are expanding their product lines. This creates more choices for consumers. However, with increased options come challenges. Consumers need to navigate varying specifications and pricing models. Knowledge about the market can help in making informed decisions.

When evaluating duplex ball valves, understanding their technical specifications is crucial. Pressure ratings determine how much pressure the valve can handle. Common ratings include ANSI and ASME standards, often denoted in psi. It’s essential to know the operating conditions to choose the right valve.

Material grades play a significant role too. Duplex stainless steel, for instance, offers high resistance to corrosion and elevated temperatures. Yet, not all applications may need such robust materials. Sometimes, standard carbon steel could suffice. However, some users overlook this.

Choosing the right valve involves more than just specifications. Consider installation ease and maintenance needs. Ensure the valve aligns with your system's requirements. This is often easier said than done. Various factors can impact the selection process, leading to confusion. Mistakes in material choice can have long-term consequences, costing both time and money. Pay attention to details, and seek guidance when needed.

Duplex ball valves are becoming essential in modern industries. Their structure offers significant advantages over traditional valves. Designed with duplex stainless steel, these valves are highly resistant to corrosion. This resistance is crucial for handling harsh chemicals and extreme temperatures. Industries often deal with aggressive fluids. A valve that can withstand these conditions reduces maintenance issues.

Another benefit of duplex ball valves is their higher strength. They provide better performance under pressure. This reliability means fewer failures and less downtime. Companies save on repair costs. However, not all duplex valves function perfectly. Some designs may still experience wear over time. Maintaining proper installation is critical.

Flow efficiency is another strong point. Duplex ball valves have lower flow resistance. Fluids move more freely, which enhances system performance. It's important to monitor flow rates. Inadequate attention could lead to unexpected issues. Selecting the right valve is a process involving careful consideration. Each application might present unique challenges.

| Valve Model | Material | Pressure Rating (PSI) | Temperature Range (°F) | Applications | Advantages |

|---|---|---|---|---|---|

| Duplex Valve A | Duplex Stainless Steel | 1500 | -30 to 350 | Oil & Gas | High resistance to corrosion |

| Duplex Valve B | Super Duplex Stainless Steel | 2000 | -50 to 400 | Chemical Processing | Superior mechanical properties |

| Duplex Valve C | Lean Duplex Stainless Steel | 1000 | -20 to 300 | Water Treatment | Lower cost with good performance |

| Duplex Valve D | Duplex Steel 2205 | 1500 | -40 to 320 | Marine Applications | Excellent stress corrosion cracking resistance |

| Duplex Valve E | Duplex Steel 2507 | 2500 | -40 to 400 | Pulp & Paper | High strength and excellent corrosion resistance |

| Duplex Valve F | Nexen Duplex | 1200 | -30 to 250 | Food & Beverage | Hygienic design with corrosion resistance |

| Duplex Valve G | Duplex Alloy | 1700 | -20 to 360 | Pharmaceuticals | Resistance to aggressive media |

| Duplex Valve H | Super Duplex 2507 | 2000 | -50 to 400 | Energy Sector | High resistance to pitting and crevice corrosion |

| Duplex Valve I | Duplex Steel 2205 | 1800 | -40 to 300 | Construction | Good performance in chloride environments |

| Duplex Valve J | Alloy 59 | 1000 | -40 to 250 | Marine & Offshore | Exceptional resistance to corrosion |

Duplex ball valves are crucial in various industries. They offer durability and resistance to corrosion. Adhering to quality standards is vital. Standards ensure performance and safety under pressure. Certifications indicate that a product meets industry guidelines.

When selecting duplex ball valves, consider the relevant certifications. Look for compliance with API, ASTM, and ANSI standards. These ensure quality materials and reliable functionality. Testing procedures should be rigorous. Proper documentation is essential to verify compliance.

Tips: Always check for a manufacturer’s certifications. This can save you future costs. Evaluate the valve’s specifications. Ensure they meet your operational needs. Don't overlook the maintenance requirements. Regular maintenance extends the valve's lifespan, avoiding costly failures. Selectivity matters in valve choices. Quality can vary greatly, so do your research.