-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

When it comes to optimizing fluid control systems, selecting the right components is essential for enhancing operational efficiency. Among these components, the Casting Ball Valve stands out as a vital element that can significantly influence performance. Understanding the various types of Casting Ball Valves available and their specific applications is crucial for engineers and procurement specialists alike.

This blog will provide valuable insights into five essential tips for selecting the perfect Casting Ball Valve that not only fits your operational needs but also boosts overall system efficiency. From material selection to design considerations, we will explore how the right choice can lead to improved reliability and reduced maintenance costs, making it a critical decision for any industrial setting.

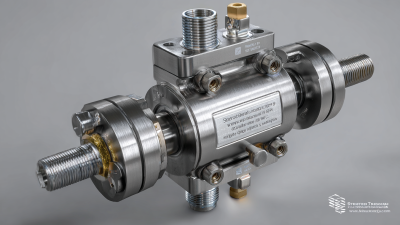

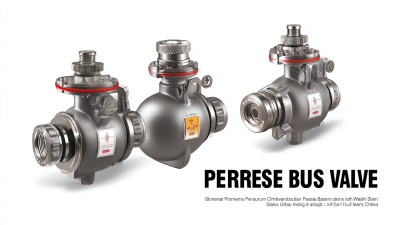

Casting ball valves play a critical role in various industrial applications by ensuring efficient fluid control in pipelines. These valves are designed to provide a tight seal, minimizing leakage and enhancing the operational reliability of processes. Industries such as oil and gas, water treatment, and chemical manufacturing rely heavily on the performance of these valves to maintain safety and efficiency. Their sturdy construction allows them to withstand high pressure and extreme temperatures, making them ideal for challenging environments.

The significance of selecting the right casting ball valve cannot be overstated. An improper choice can lead to operational inefficiencies, increased maintenance costs, and even catastrophic failures. Factors such as valve material, size, and pressure rating are essential considerations that directly impact valve performance. By understanding these key elements, industrial operators can make informed decisions that not only boost efficiency but also prolong the lifespan of their systems. Investing in the right casting ball valves ultimately contributes to a more reliable and effective operational framework, ensuring that industrial applications run smoothly and safely.

| Tip | Description | Benefits | Considerations |

|---|---|---|---|

| 1. Assess Material Compatibility | Choose a valve material that resists corrosion and is compatible with the fluids being handled. | Increased lifespan and reduced maintenance costs. | Ensure fluid composition is well-known. |

| 2. Check Pressure Ratings | Select a valve with pressure ratings suited to the specific application. | Enhanced safety and reliable performance. | Test your system to determine maximum pressure requirements. |

| 3. Evaluate Size and Flow Requirements | Ensure the valve size matches the pipeline to optimize flow. | Improved flow rates and efficiency. | Consider future expansion needs of the system. |

| 4. Understand the Actuation Method | Choose between manual, electric, or pneumatic actuation based on operational needs. | Increased operational control and automation. | Assess available power sources and space for installation. |

| 5. Look for Quality Certifications | Select valves certified by relevant industry standards for quality assurance. | Assurance of safety and performance reliability. | Research and verify certifications that apply to your industry. |

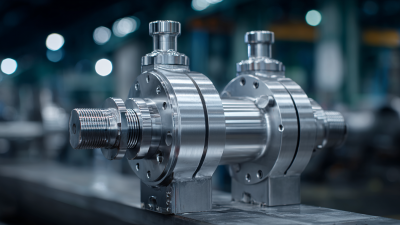

When selecting a casting ball valve, understanding the key features that contribute to efficiency is essential. High-quality casting ball valves are designed to handle high pressures and temperatures, often rated for up to 600 psi and temperatures exceeding 400°F, which makes them suitable for a wide range of industrial applications. The valve's body material significantly impacts its performance; materials like stainless steel or carbon steel offer durability and corrosion resistance, essential for maintaining operational integrity in challenging environments.

In addition to material, the design of the ball valve plays a crucial role in its efficiency. Look for valves with a full port design, which minimizes pressure drop and allows for better flow rates—data suggests that full port valves can enhance flow efficiency by 30% compared to standard port designs. Furthermore, consider the method of actuation; valves equipped with automated actuators not only boost responsiveness but also reduce labor costs by approximately 20%, as per industry studies.

By focusing on these key features, businesses can ensure they select casting ball valves that not only meet current operational demands but also promote long-term efficiency and cost savings.

When it comes to selecting the right casting ball valve, proper sizing is crucial for ensuring maximum efficiency and effectiveness in your system. One of the key considerations is the valve's diameter. Choosing a diameter that matches the flow requirements of your piping system can significantly reduce pressure drop and ensure optimal flow rates. It's essential to assess the flow capacity needed for your application and select a valve that can accommodate those parameters without being excessively oversized, which can lead to turbulence and inefficiency.

Another important factor to consider is the working pressure and temperature of your system. Ensure that the casting ball valve you choose can handle the specific operating conditions without compromising safety or functionality. This involves understanding the materials used in the valve's construction and ensuring they are compatible with the fluids being transported. Additionally, considering the valve's end connections and how they integrate with your existing system can aid in selecting a valve that not only fits physically but also enhances overall system performance. Taking these sizing and compatibility considerations into account will help you make the best choice for boosting efficiency in your operations.

This chart illustrates the importance of various factors in selecting the perfect casting ball valve to enhance efficiency. The data showcases the percentage of users prioritizing each feature based on a survey conducted among industry professionals.

When it comes to selecting a casting ball valve, one of the most critical considerations is material selection. The composition of the valve directly influences its performance, durability, and resistance to various environmental factors. Different materials, such as stainless steel, brass, and plastic, offer unique advantages and disadvantages. For instance, stainless steel is known for its excellent corrosion resistance and strength, making it ideal for high-pressure applications. On the other hand, brass is a more cost-effective option that provides good durability in less corrosive environments.

Additionally, it’s essential to consider the specific application of the valve when choosing the material. If the valve will be used in a highly corrosive environment, selecting a material with higher resistance, like a specialty alloy or a coated valve, can significantly extend its lifespan and reduce maintenance costs. Similarly, temperature and pressure ratings should align with the valve material to prevent failures due to thermal stress or mechanical loads. Evaluating these factors carefully ensures that the casting ball valve not only meets operational needs but also contributes to enhanced efficiency in the system.

When it comes to ensuring the longevity and optimal performance of your casting ball valve, regular maintenance is key. One of the most effective maintenance tips is to conduct routine inspections. Checking for signs of wear, such as leaks or corrosion, can help identify potential issues before they escalate. Additionally, it's essential to regularly clean the valve to prevent sediment buildup, which can hinder its operation. Using the appropriate cleaning solutions will help maintain both the valve's integrity and performance.

Another important aspect of maintenance is lubrication. Ensuring that all moving parts are properly lubricated keeps the valve functioning smoothly and reduces the risk of sticking or seizing. It's advisable to use lubricants that are compatible with the valve's materials to avoid any adverse reactions. Lastly, keeping the valve in a controlled environment can significantly enhance its lifespan by protecting it from extreme temperatures and corrosive elements. Adhering to these maintenance practices not only boosts the efficiency of your casting ball valve but also contributes to significant long-term savings by reducing the need for costly repairs or replacements.