-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

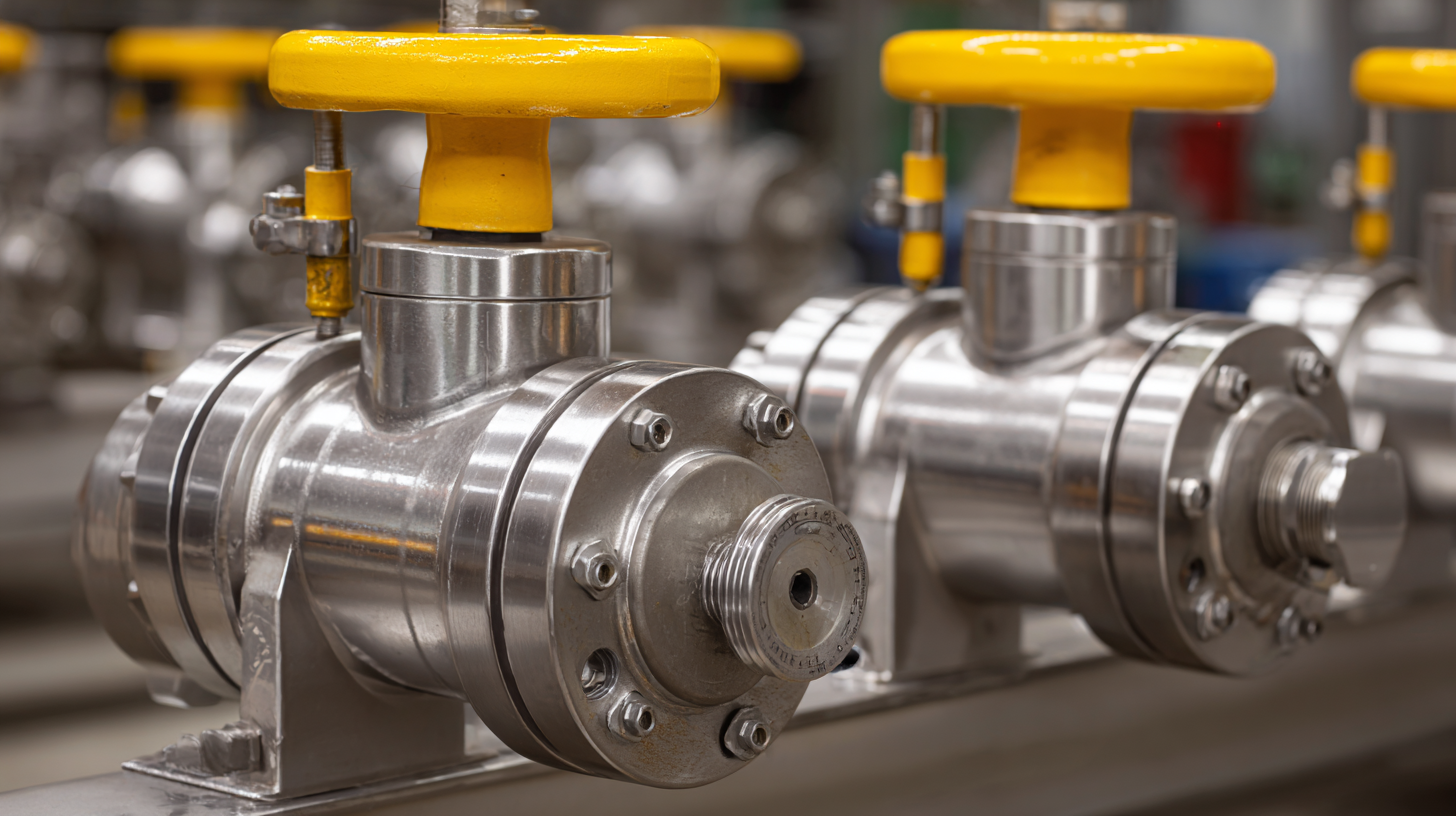

When it comes to sourcing the perfect Manual Ball Valves for various industrial applications, the complexities can be overwhelming. With the increasing global demand for reliable and efficient flow control solutions, selecting the right valve requires careful consideration and a strategic approach. This blog aims to provide a comprehensive checklist that will guide you through the essential steps in the sourcing process, ensuring you find the ideal Manual Ball Valves that meet your specifications and performance standards. From evaluating suppliers’ credentials to assessing product quality and compliance with industry regulations, this resource will empower you to make informed decisions. Whether you are a seasoned procurement professional or entering the world of valve sourcing for the first time, this checklist will be an invaluable tool in optimizing your selection process and achieving successful outcomes.

The global market for manual ball valves has witnessed a significant transformation in recent years, with Chinese manufacturers emerging as dominant players. According to a report by Market Research Future, the market size for manual ball valves was valued at approximately $3.2 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2022 to 2030. This growth can be largely attributed to the competitive pricing and advanced production capabilities of Chinese manufacturers, who have increasingly invested in research and development to enhance quality.

Chinese companies now account for over 40% of the global manual ball valve production, largely due to their ability to meet diverse customer needs while maintaining cost-effectiveness. A recent analysis by Research and Markets highlighted that the demand for manual ball valves in industries like oil and gas, water treatment, and chemical processing has surged, propelling Asian manufacturers to the forefront. This rising dominance is supported by China's robust manufacturing infrastructure and a well-established supply chain, positioning them as a go-to source for buyers seeking reliable and affordable solutions in the manual ball valve sector.

| Region | Manufacturer Dominance (%) | Production Capacity (Units/Year) | Average Price Range (USD) |

|---|---|---|---|

| North America | 25 | 5,000,000 | 50-200 |

| Europe | 30 | 4,000,000 | 60-250 |

| Asia (including China) | 40 | 10,000,000 | 30-150 |

| Latin America | 3 | 1,500,000 | 40-180 |

| Africa | 2 | 800,000 | 45-170 |

The demand for manual ball valves is increasingly influenced by several key market trends that are shaping the industry landscape worldwide. One significant trend is the growing emphasis on sustainability and environmental regulations. As industries strive to reduce their carbon footprints and improve energy efficiency, there has been a notable shift toward valves that not only meet operational needs but also align with eco-friendly practices. This shift is prompting manufacturers to innovate and produce more energy-efficient ball valves that are durable and contribute to a lower environmental impact.

Another major trend impacting the manual ball valve market is the expansion of emerging economies. As regions such as Asia-Pacific and Latin America experience rapid industrial growth, the demand for reliable and efficient flow control solutions continues to rise. Industries such as oil and gas, water treatment, and chemical processing are particularly driving this demand. This growth provides opportunities for suppliers to tap into new markets, but it also necessitates an understanding of local regulations and industry standards, making strategic sourcing essential for meeting the unique requirements of these regions.

The manual ball valve industry is undergoing significant transformations, largely driven by technological advancements that enhance sourcing efficiency on a global scale. According to a recent report by MarketsandMarkets, the global ball valve market is projected to grow from USD 9.1 billion in 2021 to USD 14.3 billion by 2026, reflecting a compound annual growth rate (CAGR) of 9.4%. This growth is attributed to the increasing demand for reliable and efficient fluid control systems across various industries, including oil and gas, water and wastewater management, and chemical processing.

One of the key innovations affecting manual ball valve sourcing is the integration of smart technologies. Automation and IoT systems have enabled real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs. A study by Research and Markets indicates that the adoption of smart valves could reduce maintenance costs by up to 30%. Additionally, advancements in materials, such as the development of corrosion-resistant alloys and advanced polymers, are enhancing the durability and lifespan of manual ball valves, thereby making them more appealing for global sourcing. As companies leverage these technological advancements, they are better positioned to meet the increasing demands of modern applications while ensuring cost-effectiveness and reliability.

When sourcing manual ball valves, understanding and evaluating the quality standards is paramount for ensuring reliability and performance. Different countries have varying standards that can significantly influence the manufacturing process, materials used, and the overall durability of the valves. For instance, American National Standards Institute (ANSI) outlines specific criteria that manufacturers must adhere to, focusing on safety and performance under pressure. In contrast, European Union regulations, particularly the Pressure Equipment Directive (PED), emphasize compliance and rigorous testing to safeguard operational integrity across various industries.

A global perspective necessitates a comprehensive evaluation of these standards, as they not only affect product safety but also impact international trade and compatibility. Companies looking to source valves need to be aware of certifications such as ISO 9001, which signifies quality management systems, and how these are viewed in different markets. By scrutinizing quality benchmarks from multiple regions, businesses can make informed decisions, ensuring that they choose suppliers whose products meet or exceed the necessary safety and performance criteria for their specific applications. This diligence in evaluating quality standards ultimately protects investments and upholds the reputation of companies in an increasingly competitive global marketplace.

This chart displays the comparison of quality standards for manual ball valves sourced from various regions around the world. It highlights the percentage of sourcing that meets international quality standards.

When sourcing manual ball valves globally, understanding regional differences in manufacturing capabilities and market requirements is crucial. For instance, countries like China and India offer competitive pricing and high production volumes, which are appealing for bulk purchases. However, the quality of the valves can vary significantly, necessitating additional quality control measures. In contrast, countries in Europe, such as Germany and Italy, may provide superior engineering and stricter quality standards, making them ideal for industries where reliability and precision are paramount.

When sourcing manual ball valves globally, understanding regional differences in manufacturing capabilities and market requirements is crucial. For instance, countries like China and India offer competitive pricing and high production volumes, which are appealing for bulk purchases. However, the quality of the valves can vary significantly, necessitating additional quality control measures. In contrast, countries in Europe, such as Germany and Italy, may provide superior engineering and stricter quality standards, making them ideal for industries where reliability and precision are paramount.

Regional preferences and standards also play a pivotal role in sourcing strategies. North America often prioritizes certification compliance, while Asian markets may focus more on cost efficiency. Therefore, businesses need to tailor their sourcing approaches based on the specific needs and regulations of the target market. By conducting a thorough comparative analysis of sourcing strategies across different regions, companies can align their procurement decisions with both their operational goals and the expectations of their customers, ensuring the successful acquisition of high-quality manual ball valves worldwide.