-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

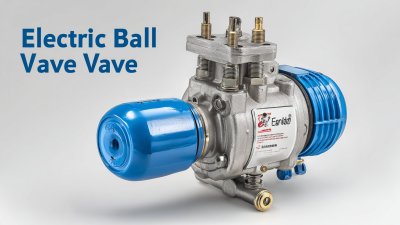

When it comes to optimizing industrial processes, selecting the right equipment is crucial, and the Electric Ball Valve is no exception. These valves play a pivotal role in controlling the flow of liquids and gases within various systems, ensuring efficiency, reliability, and precision. However, with a myriad of options available on the market, choosing the most suitable Electric Ball Valve for your specific application can be daunting.

Factors such as size, material compatibility, voltage requirements, and control mechanisms influence performance and longevity. In this guide, we will delve into essential tips and considerations, helping you navigate the complexities of Electric Ball Valve selection.

By understanding these critical aspects, you can enhance your operational efficiency and maintain higher safety standards in your industrial applications.

When selecting the right electric ball valve for industrial applications, it's essential to understand the different types available. Electric ball valves are primarily categorized based on their actuator types, which can be either on-off or modulating. On-off valves are designed for applications that require complete opening or closing of the flow, making them ideal for simple control tasks. In contrast, modulating valves allow for variable control of flow, which is crucial for processes requiring precise regulation.

**Tips:** Consider the specific requirements of your application when choosing between these types. Think about whether you need full shut-off capabilities or more nuanced control over flow rates.

Additionally, electric ball valves can vary in terms of construction materials. Common materials include stainless steel, brass, and PVC, each offering unique benefits depending on the application environment. For instance, stainless steel valves are highly durable and corrosion-resistant, making them suitable for harsh chemicals, while PVC valves are lightweight and can be more cost-effective for less demanding situations.

**Tips:** Evaluate the fluids being handled, the pressure and temperature conditions, and choose a valve material that aligns with these factors for optimal performance and longevity.

When selecting electric ball valves for industrial applications, especially in critical sectors such as nuclear power plants, it is essential to consider several key features. Firstly, the valve's operational stability and safety are paramount, as any malfunction can have significant consequences. This entails evaluating the valve's design, materials, and manufacturing quality to ensure it can withstand demanding conditions. Moreover, understanding the remaining useful life prediction techniques is crucial in maintaining the reliability of these valves, thereby enhancing their longevity and performance.

Another essential feature to consider is the type of actuator used. Electric actuators are increasingly favored over hydraulic systems due to their precision and repeatability, leading to lower operational costs. It’s important to meticulously assess the actuator's power requirements, response time, and compatibility with existing systems. Additionally, the sizing of the valve must be determined based on flow requirements and the specific processes involved, ensuring that the chosen electric ball valve meets the operational demand effectively. The integration of automated options can further improve operational efficiency, making it vital to weigh these technological advancements when making a decision.

When selecting the right electric ball valve for industrial applications, assessing compatibility with existing systems and processes is crucial. Start by evaluating the operational requirements of your current setup. Consider the valve's size, pressure ratings, and flow characteristics to ensure they align with your pipeline specifications. Different applications may require valves made from specific materials that can withstand varying temperatures and chemical exposures. Therefore, matching the valve materials with the fluids being transported is essential to prevent leaks and corrosion.

Additionally, it’s important to assess the control systems currently in use. Determine if the electric ball valve can integrate seamlessly with the existing automation systems, such as PLCs or DCS. Look for valves that support standardized communication protocols such as Modbus, Ethernet/IP, or Profibus, which can facilitate better data exchange and monitoring. Lastly, evaluating the overall ease of installation and maintenance will contribute to the efficient performance of the valve in your industrial environment, ensuring minimal downtime and optimal functionality.

| Criteria | Importance Level | Compatibility with Existing Systems | Expected Lifespan | Price Range ($) |

|---|---|---|---|---|

| Size | High | Must match pipe diameter | 10-15 years | 200 - 500 |

| Material | High | Must be corrosion-resistant | 10-20 years | 150 - 700 |

| Actuator Type | Medium | Electric or pneumatic | 5-15 years | 100 - 400 |

| Pressure Rating | High | Needs to fit system pressure | 10-25 years | 300 - 800 |

| Control Options | Medium | Manual or smart control | 5-20 years | 250 - 900 |

When selecting the right electric ball valve for industrial applications, it is crucial to evaluate performance and efficiency ratings. According to the 2022 Market Research Report on Industrial Valves, electric ball valves have shown an impressive efficiency rating of 90% to 95% in various flow control scenarios, minimizing energy losses compared to traditional valves. This high efficiency can lead to significant cost savings, with some industries reporting reduced operational costs by approximately 20% over five years when switching to electric ball valves.

Moreover, performance metrics such as response time and torque requirements also play a pivotal role in the selection process. A study by the International Journal of Fluid Mechanics indicated that electric ball valves typically offer faster actuation, averaging a response time of under 2 seconds, which is critical in processes requiring precise control. In high-pressure environments, the torque ratings of these valves—often rated between 50 to 100 Nm for larger sizes—ensure reliability under demanding conditions. Therefore, when assessing various electric ball valve options, focusing on these performance and efficiency metrics is essential for optimizing industrial operations.

When choosing an electric ball valve for industrial applications, the balance between cost and quality is paramount. According to recent industry reports from the Valve Manufacturers Association, a high-quality electric ball valve can last up to 15 years, reducing long-term operational costs despite a higher initial price. Conversely, lower-cost options may incur higher maintenance and replacement expenses, especially in demanding environments. Investing in durable materials and proven technology not only ensures reliability but can also improve overall system efficiency.

Tips for selecting the right valve include assessing your application requirements carefully. Consider the fluid types, pressure levels, and temperature extremes your valve will face. Don't hesitate to consult manufacturer datasheets to compare specifications—models with higher certificated ratings may offer better performance and longevity.

Additionally, while budget constraints are a reality, prioritizing reputable brands known for their performance and quality can yield significant returns. A study by the National Institute of Standards and Technology indicates that choosing quality valves in critical applications can enhance system reliability by up to 30%. Make your investment count by selecting valves that align with both performance goals and financial constraints to achieve the best value.