-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

A Screwed Ball Valve is an essential component in many piping systems. This valve type is designed for controlling fluid flow. Its simple yet efficient mechanism allows for precise regulation. The construction includes a spherical disc that rotates to open or close the flow path.

When considering a Screwed Ball Valve, one must appreciate its advantages. However, they also have limitations. For instance, improper installation can lead to leaks. Maintenance is crucial for longevity, which some overlook. Regular checks are necessary to ensure functionality.

Understanding a Screwed Ball Valve's operation is vital for professionals. It may seem straightforward, yet many challenges arise in its use. Choosing the right valve can significantly impact system performance. Careful analysis and application are essential for optimal results.

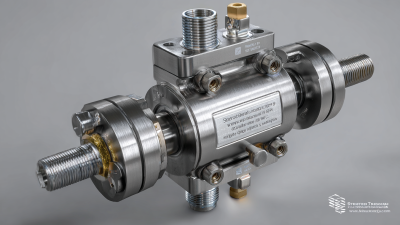

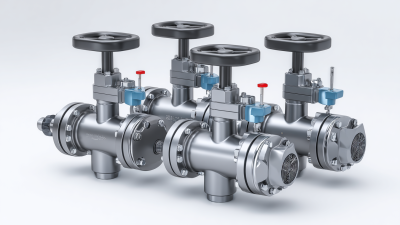

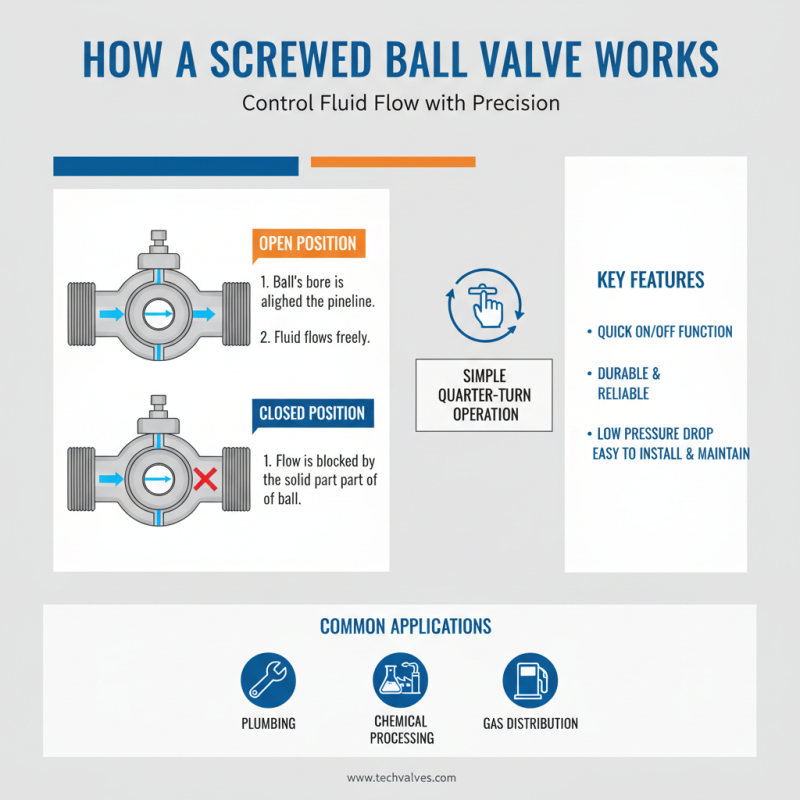

A screwed ball valve is a mechanical device used to control fluid flow. It features a spherical disc, or ball, with a hole in the center. When the ball turns, it either allows or blocks the flow of the fluid. This simple yet effective mechanism is popular in various industries, including plumbing, chemical processing, and gas distribution.

The design of a screwed ball valve allows for quick operation. A quarter turn can open or close the valve fully. This is particularly advantageous in emergency situations where rapid action is needed. However, improper installation can lead to leaks, which may cause critical failures. It's essential to ensure proper alignment during installation and maintenance.

Screwed ball valves come in different sizes and materials, making them versatile. They can withstand high pressure and temperature changes. Still, users must assess their specific needs carefully. Sometimes, a valve may not perform as expected. Monitoring and regular checks can prevent future issues. Choosing the right valve for a specific application often requires some thought and experience.

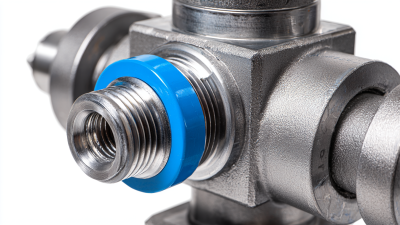

Screwed ball valves are popular for their reliability and ease of use. One crucial design feature is the threaded connection. This allows for quick installation and secure assembly. According to industry reports, about 20% of valve failures can be attributed to improper installation. Thus, precise threading is vital to ensure proper sealing.

Another significant aspect is the ball mechanism. The ball controls the flow of the fluid. When rotated, it completely opens or closes the passage. This design allows for minimal pressure loss, promoting efficiency. Many manufacturers claim these valves can achieve a flow coefficient (Cv) of up to 400, depending on the size.

Material selection is also essential in the design of screwed ball valves. Stainless steel is common, offering durability and resistance to corrosion. However, it can be costly. Reports suggest that using alternative materials can cut costs by nearly 30%. Yet, these alternatives may not always provide the same longevity. Careful consideration is required when selecting materials to balance cost and performance.

| Feature | Description |

|---|---|

| Material | Typically made of brass, stainless steel, or plastic |

| Type | Screwed ball valves are usually full port or reduced port |

| Operating Mechanism | Rotating the ball allows fluid to flow through or be stopped |

| Connection Type | Screwed connections for secure installation |

| Applications | Widely used in plumbing, gas, water supply, and irrigation systems |

| Advantages | Quick on-off operation, minimal flow resistance, durable |

| Limitations | Not suitable for throttling applications due to flow stability |

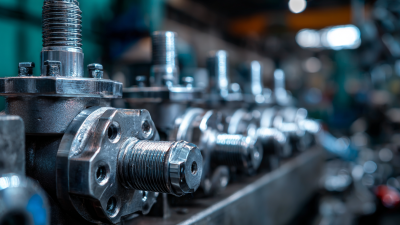

Screwed ball valves are essential in many industries. They control the flow of liquids and gases. Their mechanical operation relies on a spherical disk that can rotate 90 degrees. The connection is made through threaded ends. This design allows for easy installation and maintenance. According to industry reports, over 40% of fluid control applications use this type of valve.

The mechanical operation is straightforward yet effective. When the handle turns, the ball rotates, either opening or closing the flow path. This creates a tight seal, preventing leaks. Many manufacturers emphasize that the precision of the threaded connection is crucial. An improper fit can lead to issues. Studies show that nearly 15% of valve failures are due to installation errors. This highlights the importance of skilled labor and quality assurance.

Another point to consider is the material choice for the valve. Common materials include stainless steel and carbon steel. Each material has unique properties that affect performance. A report indicated that the failure rate of valves made from inappropriate materials can be as high as 20%. Thus, understanding the operational environment is vital for selecting the right type of screwed ball valve.

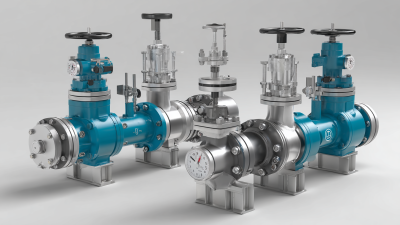

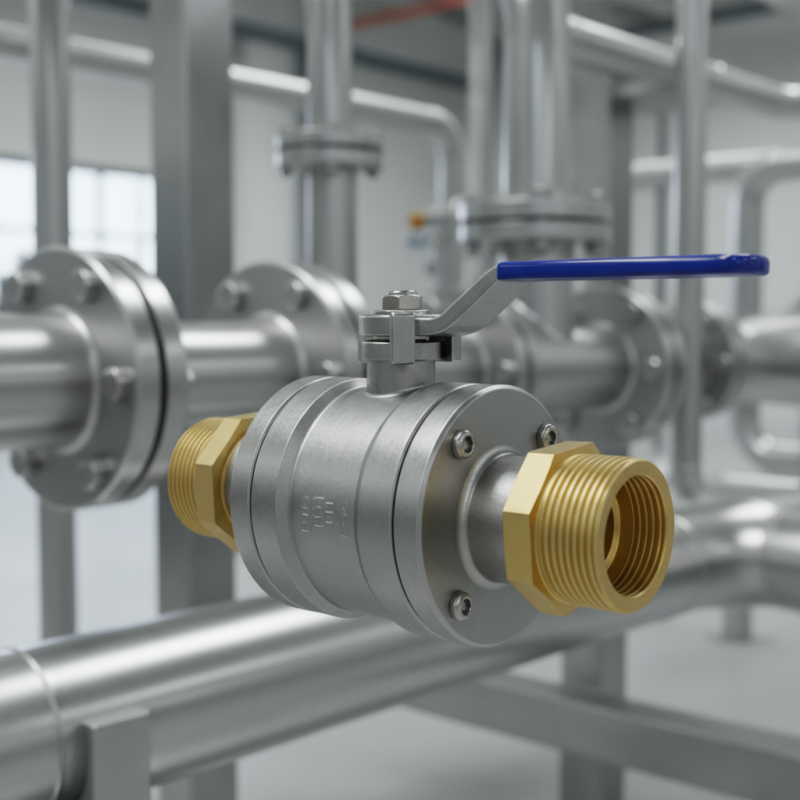

Screwed ball valves are popular in many industries. They offer several advantages that make them appealing. One of the main benefits is their ease of installation. The threaded design allows for a secure and leak-tight connection. This feature reduces maintenance issues.

Another advantage is versatility. Screwed ball valves can handle different media, including water and gases. Their simple mechanism also ensures reliable operation. This design reduces the chance of failure.

However, choosing the wrong valve size can lead to inefficiencies. Sometimes, users overlook the importance of correct sizing.

Cost-effectiveness is another key point. Screwed ball valves often require less initial investment. They are generally more affordable than other valve types. However, people sometimes sacrifice quality for price. This can lead to problems down the line. Ultimately, while the benefits are clear, it is crucial to consider long-term consequences. Choosing the right valve requires careful thought and planning.

Screwed ball valves are versatile tools used in various industries. They function well in managing the flow of liquids and gases. One common application is in plumbing systems. These valves help to control water flow efficiently. Their design allows for easy installation. Simple screw fittings make them user-friendly.

Another application is in the oil and gas industry. Screwed ball valves provide reliable sealing under pressure. They can handle various temperatures and are essential in pipelines. In food processing, they ensure sanitary conditions. The materials used are often resistant to corrosion, which is vital for safety.

Though effective, screwing them in requires careful handling. An improper fit can lead to leaks. Maintenance is crucial; periodic checks can prevent future problems. Users must be aware of wear and tear. Identifying issues early can save costly repairs later on. These considerations highlight the need for proper training and vigilance.