-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

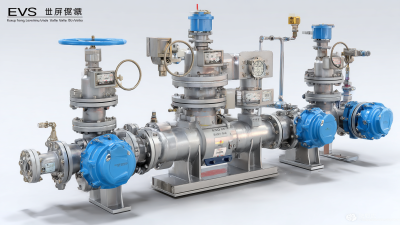

In today's industrial landscape, the efficiency and reliability of fluid control systems are paramount, and one critical component often overlooked is the Tubing Ball Valve. Selecting the right type of Tubing Ball Valve can significantly impact performance efficiency, ensuring smooth operations in various applications, from oil and gas to chemical processing. With a plethora of options available, it's essential to understand the unique characteristics and benefits of different types of valves to optimize your selection process. This blog will delve into the essential factors to consider when choosing a Tubing Ball Valve, emphasizing the importance of design, materials, and operational parameters that elevate performance efficiency. Whether you are a seasoned engineer or new to the field, enhancing your knowledge of Tubing Ball Valves will lead to more informed decisions, minimizing costs and maximizing system productivity.

The selection of tubing ball valves is critical to ensuring optimal performance and efficiency in various applications, particularly in the context of the emerging carbon capture and sequestration (CCS) technologies. These valves are vital components in managing the flow of supercritical carbon dioxide in pipelines and injection systems, where precise control and reliability are paramount. According to recent industry reports, improper valve selection can lead to increased operational costs and reduced system efficiency by up to 20%.

The selection of tubing ball valves is critical to ensuring optimal performance and efficiency in various applications, particularly in the context of the emerging carbon capture and sequestration (CCS) technologies. These valves are vital components in managing the flow of supercritical carbon dioxide in pipelines and injection systems, where precise control and reliability are paramount. According to recent industry reports, improper valve selection can lead to increased operational costs and reduced system efficiency by up to 20%.

Understanding the specific requirements of the application is essential. Factors such as pressure rating, temperature range, and fluid characteristics must be thoroughly assessed to choose the right tubing ball valve. The global push for carbon dioxide injection projects highlights the necessity of employing valves that can withstand the demanding conditions associated with supercritical fluids. Furthermore, studies show that utilizing high-quality valves designed for these environments can enhance flow control and minimize leakage, directly contributing to the overall success of carbon dioxide management systems.

As industries move toward more sustainable practices, the importance of proper tubing ball valve selection cannot be overstated. With the right choice, operators can significantly enhance the operational efficiency of their systems, thus supporting wider environmental goals while complying with increased regulatory standards in carbon emissions management.

When selecting tubing ball valves for optimal performance efficiency, it is crucial to identify key performance metrics that can significantly impact operational effectiveness. One of the primary metrics to consider is flow rate, which measures the volume of fluid that passes through the valve in a specific period. Understanding the maximum and minimum flow rates can help in selecting a valve that minimizes pressure drops and maximizes throughput, enabling better system efficiency.

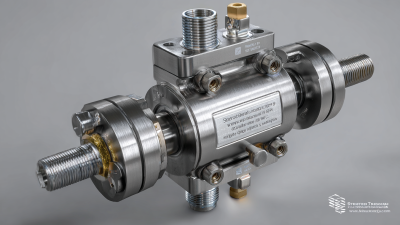

Another vital performance metric is the overall leakage rate, which indicates how well the valve seals when closed. A low leakage rate is essential in preserving fluid integrity and reducing waste, especially in applications involving expensive or hazardous materials. Additionally, assessing the temperature and pressure ratings of the valve ensures that it can withstand the operational conditions without compromising safety or functionality. By closely examining these key performance metrics, operators can make informed decisions that lead to enhanced performance and reliability of tubing ball valves in their systems.

| Performance Metric | Importance Level | Recommended Value | Actual Performance | Remarks |

|---|---|---|---|---|

| Operating Pressure (psi) | Critical | 1500 | 1400 | Below recommended for optimal performance |

| Flow Rate (GPM) | High | 500 | 450 | Consider upgrading valve size |

| Temperature Range (°F) | Moderate | -20 to 300 | -10 to 250 | Check for insulation requirements |

| Material Compatibility | Critical | Steel, Stainless Steel | Stainless Steel | No issues reported |

| Leakage Rate (cc/min) | High | < 0.1 | 0.05 | Meets performance standards |

When selecting tubing ball valves, evaluating materials and design considerations is crucial for enhancing performance efficiency. The choice of material significantly impacts not only the valve's durability but also its resistance to corrosive environments. For instance, studies indicate that stainless steel valves exhibit a lifespan increase of up to 50% over traditional carbon steel options in harsh chemical processes (Source: Valve Manufacturers Association). Moreover, advanced composite materials are gaining traction, demonstrating improved weight-to-strength ratios, which can lead to easier installation and reduced maintenance costs.

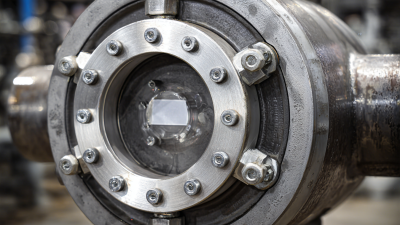

Design considerations, such as the ball valve's flow path and sealing technology, also play a pivotal role in optimizing efficiency. Reports show that streamlined flow designs can reduce pressure drop by 30% compared to conventional designs (Source: American Society of Mechanical Engineers). Additionally, utilizing enhanced sealing mechanisms, like fluoropolymer coatings, can lead to significant reductions in leakage rates, often less than 0.01% of the total flow. These advancements not only promote better fluid control but also contribute to overall energy savings in pipelines, resulting in more sustainable operations across various industries.

This chart illustrates the efficiency ratings of different tubing ball valve materials. Material selection is critical for enhancing performance efficiency in various applications. The ratings demonstrate how each material fares in terms of operational performance, helping inform better selection decisions.

When selecting tubing ball valves, understanding the operating conditions is crucial for optimizing performance efficiency. The media type, pressure, temperature, and flow rates all directly influence how well a valve operates. For instance, aggressive fluids may require specific materials, such as PTFE lining, to ensure durability and prevent leakage. By assessing these factors, engineers can better determine the appropriate type of valve that will perform effectively under specific conditions.

The rising demand for PTFE lined valves reflects this need for tailored solutions in various industries. With the market for PTFE lined ball valves projected to grow from $64.14 million in 2024 to $84.01 million by 2032, at a CAGR of 3.4%, industries are increasingly recognizing the importance of selecting the right valve to enhance operational efficiency. Analyzing operating conditions not only improves the longevity of the valve but also minimizes maintenance costs and downtime, ultimately leading to a more efficient system overall.

When it comes to ensuring the longevity and performance of tubing ball valves, a thorough maintenance and inspection checklist is essential. Regular inspection not only prevents unexpected failures but also extends the service life of these critical components. Start by assessing the valve's operational environment: check for signs of corrosion, wear, or any signs of leakage that might indicate maintenance is needed. Additionally, maintain proper documentation of inspection dates, findings, and any modifications made over time.

To further enhance performance efficiency, consider implementing a schedule for routine maintenance. This could include tasks such as lubricating seals and checking for proper alignment. By adhering to a regular maintenance routine, similar to the recommendations for keeping a vehicle in optimal condition, you can proactively address minor issues before they evolve into costly repairs. Creating a checklist tailored to your specific needs will ensure that nothing is overlooked and will provide a blueprint for best practices in valve management.