-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In today's fast-paced industrial landscape, achieving optimal efficiency is paramount, and one of the critical components contributing to this goal is the Forged Steel Ball Valve. These valves, known for their durability and reliability, play a vital role in fluid control systems across various sectors.

However, to truly harness their potential, it is essential to implement strategies that maximize their performance and lifespan. This blog will provide a comprehensive checklist of top strategies tailored for industrial applications, aimed at enhancing the efficiency of Forged Steel Ball Valves.

By following these expert recommendations, engineers and operators can minimize downtime, improve operational reliability, and ultimately drive productivity within their facilities. Join us as we delve into the key practices that ensure these robust devices are utilized to their fullest advantage, leading to significant operational gains.

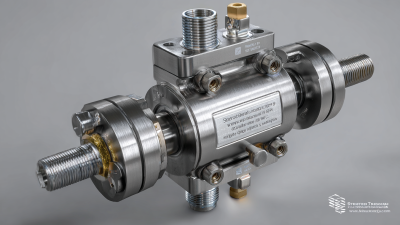

Forged steel ball valves have become a crucial component in industrial systems, providing numerous benefits that enhance operational efficiency. Their sturdy construction and precision design allow for precise flow control, which is vital in sectors ranging from oil and gas to water management. The resilience of forged steel against high pressures and temperatures not only improves system reliability but also reduces potential maintenance costs over time.

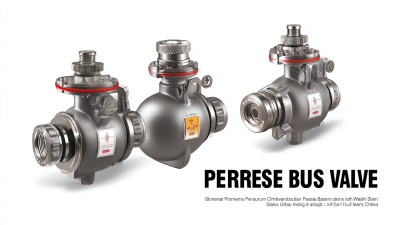

Tips for optimizing efficiency with forged steel ball valves include selecting the appropriate size and type for your specific application, as using an oversized valve can lead to flow turbulence, diminishing performance. Regular maintenance is also essential; routine inspections and timely replacements ensure that valves operate at peak efficiency, preventing unplanned downtimes.

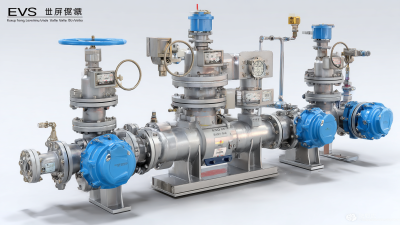

Another strategy is to invest in modern actuators that can integrate with forged steel ball valves. Advanced actuator technologies can provide better response times and automation, further enhancing system performance. As industries increasingly recognize the importance of digital innovation, adopting smart technologies that monitor valve performance can lead to better resource management and reduced operational costs.

The chart displays various efficiency metrics related to the implementation of forged steel ball valves in industrial systems. The flow rate highlights the capability of the valves, while the pressure drop indicates operational effectiveness. The operating temperature shows the environmental tolerance, and installation time along with maintenance frequency provides insights into overall operational efficiency.

Forged steel ball valves are increasingly becoming the go-to choice for industrial applications due to their exceptional strength and durability. Key features that enhance efficiency in these valves include their high pressure ratings and resistance to extreme temperatures. The robust construction allows them to operate in harsh environments without compromising performance, thereby minimizing downtime and maintenance costs.

To maximize efficiency, consider implementing regular maintenance checks. This not only ensures the longevity of the valves but also catches potential issues before they escalate. Additionally, ensure that the valve selection matches the specific requirements of your system, such as pressure and flow rate. This alignment is crucial for maintaining optimal operational efficiency.

Another important tip is to invest in high-quality seals and components. Superior materials reduce the chances of leaks and enhance the overall performance of the ball valves. This commitment to quality leads to less energy loss and a more reliable system, ultimately boosting efficiency in your industrial operations.

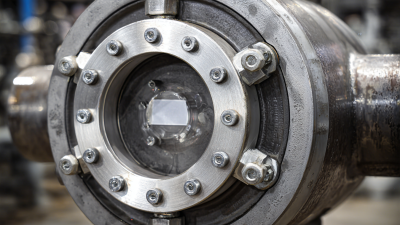

When it comes to the installation and maintenance of forged steel ball valves in industrial applications, adherence to best practices is crucial for maximizing efficiency and longevity. First and foremost, proper installation is essential to prevent leaks and ensure optimal performance. This involves checking the alignment of the valve in relation to the pipeline, ensuring that it is free from debris, and using appropriate seals and fittings. During installation, it is also important to follow the manufacturer's specifications regarding torque settings and tightening sequences to avoid damaging the valve.

Regular maintenance is equally important to keep forged steel ball valves functioning effectively over time. Industry experts suggest implementing a scheduled inspection routine that includes checking for signs of wear and tear, such as corrosion or irregular valve operation. Lubrication of moving parts should also be performed according to the manufacturer's guidelines to reduce friction and enhance the valve's responsiveness. Additionally, staff training on troubleshooting potential issues, such as leaks or performance drops, can empower teams to address problems before they escalate, thereby ensuring the integrity and efficiency of the entire system.

When comparing forged steel ball valves to other valve types, it is essential to consider several key performance metrics, including durability, flow efficiency, and operational costs. According to a recent report by the Global Valve Market Research Institute, forged steel ball valves exhibit a remarkable lifespan, outlasting traditional gate and globe valves by 15-20%, particularly in high-pressure environments. This longevity is crucial in industries such as oil and gas, where the costs associated with valve replacements can be significant.

Additionally, flow efficiency is a critical factor in industrial applications. Forged steel ball valves provide a lower pressure drop compared to their gate and globe counterparts, resulting in greater energy efficiency. A study published in the Journal of Industrial Flow Dynamics indicates that forged steel ball valves can improve flow rates by over 30%, translating to substantial savings in energy costs. This performance advantage is vital for manufacturers aiming to optimize production processes and reduce operational overheads, reinforcing the preference for forged steel ball valves in demanding industrial settings.

| Valve Type | Flow Efficiency (%) | Operating Pressure (psi) | Temperature Resistance (°F) | Lifespan (Years) | Maintenance Frequency (Months) |

|---|---|---|---|---|---|

| Forged Steel Ball Valve | 95% | 3000 | 450 | 20 | 24 |

| Gate Valve | 85% | 2500 | 350 | 15 | 18 |

| Globe Valve | 80% | 2000 | 400 | 10 | 12 |

| Ball Valve | 90% | 1500 | 300 | 12 | 6 |

Forged steel ball valves are essential in various industrial applications due to their reliability and efficiency. Real-world case studies highlight how these valves have significantly improved operational performance. For instance, a leading oil and gas company reported a 20% reduction in downtime after replacing traditional gate valves with forged steel ball valves, showcasing their superior flow control and minimal leakage. This transition not only enhanced system reliability but also contributed to substantial cost savings in maintenance.

To maximize the efficiency gains offered by forged steel ball valves, companies should consider regular maintenance and monitoring. Implementing a scheduled inspection program can help identify wear and tear early, ensuring valves operate at peak efficiency. Additionally, training staff on the specific operational advantages of ball valves can lead to better usage practices, ultimately contributing to reduced energy consumption and increased productivity.

Another tip is to assess the application environment to ensure the correct valve type is selected. Using valves that are specifically designed for high-pressure and high-temperature environments can greatly enhance performance and longevity. Tailoring valve specifications to match operational needs will ensure you get the most out of your investment, leading to impressive efficiency gains in your industrial applications.