-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

The upcoming 138th Canton Fair in 2025 is set to showcase groundbreaking developments in the manufacturing and application of Carbon Steel Ball Valves, which are increasingly vital in various industrial sectors.

According to a recent market analysis by Research and Markets, the global ball valve market is projected to reach USD 21.5 billion by 2026, driven by the growing demand for efficient flow control technologies in oil and gas, water treatment, and chemical processing industries.

Carbon Steel Ball Valves, known for their durability and resistance to corrosion, play a crucial role in optimizing operations and reducing maintenance costs across these sectors.

As leading manufacturers gather to introduce innovative designs and enhanced functionalities, this year's event promises to be a pivotal platform for industry stakeholders looking to leverage advancements in this essential component of fluid handling systems.

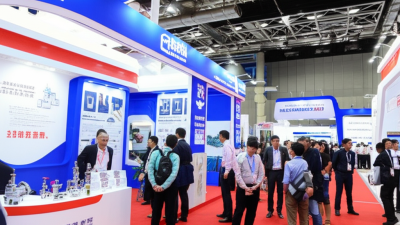

At the 138th Canton Fair in 2025, the spotlight shone brightly on the latest innovations in carbon steel ball valves, showcasing cutting-edge designs that promise to revolutionize the industry. According to a recent report by MarketsandMarkets, the global ball valve market is projected to reach USD 13.5 billion by 2026, growing at a CAGR of 6.2% from 2021 to 2026. This growth not only reflects the increasing demand for efficient flow control solutions in various sectors, but also highlights the urgent need for advancements in valve technology.

Exhibitors at the fair introduced a range of innovative designs focused on enhancing reliability and performance. For instance, new lightweight carbon steel materials with improved corrosion resistance were featured, offering up to 30% better lifespan compared to traditional models. Additionally, some manufacturers showcased ball valves with integrated smart technology, which allows for real-time monitoring and improved control over fluid dynamics. This aligns with the projected rise of smart industrial solutions, which, according to a report by Mordor Intelligence, is expected to see a robust growth rate of 8.9% over the next five years, emphasizing the importance of incorporating technology into industrial hardware.

The upcoming 138th Canton Fair in 2025 will spotlight groundbreaking developments in carbon steel ball valves, particularly focusing on how advancements in materials are reshaping their performance and durability. Recent industry reports indicate that the integration of higher-grade carbon steel and innovative coatings has enhanced valve longevity by over 30%. Such improvements are crucial as manufacturers strive to meet the increasing demands for reliability in various applications, including oil and gas, water treatment, and chemical processing.

Furthermore, advances in manufacturing techniques, such as precision forging and advanced welding technologies, have allowed for more robust products that can withstand extreme temperatures and corrosive environments. A study by Global Valve Market Insights reported that the introduction of high-tensile carbon steel has reduced failure rates in ball valves by 25%, underscoring the significance of material advancements. As trade shows like the Canton Fair facilitate the exchange of ideas and technological breakthroughs, the future of carbon steel ball valves looks promising, with the industry poised to deliver solutions that cater to both performance and environmental sustainability.

| Feature | Performance Indicator | Material Type | Durability Rating (Years) | Innovative Feature |

|---|---|---|---|---|

| Flow Rate | 1500 L/min | High Carbon Steel | 15 | Self-Cleaning Mechanism |

| Temperature Resistance | -40°C to 200°C | Alloy Steel | 20 | Insulated Body Design |

| Leak Rate | 0.01% of Flow | Stainless Steel | 25 | Enhanced Sealing Technology |

| Pressure Capability | 300 PSI | Carbon Steel with Coating | 18 | Corrosion-Resistant Coating |

The 138th Canton Fair in 2025 will showcase significant innovations in carbon steel ball valves, reflecting the growing demand for these essential components in various industrial applications. As industries continue to expand, the need for reliable and efficient fluid control systems becomes increasingly critical. Carbon steel ball valves, known for their durability and resistance to high pressures and temperatures, are positioned to meet this rising demand, providing solutions that enhance operational efficiency.

Market trends indicate a shift towards the use of carbon steel ball valves in sectors such as oil and gas, manufacturing, and water treatment. Their versatility and performance in demanding environments make them a preferred choice among engineers and procurement specialists. The fair will highlight advancements in design and materials, allowing manufacturers to better cater to the specific requirements of their clients across different industries.

As a result, attendees can expect to discover innovative products that not only improve functionality but also reduce maintenance costs and enhance safety standards in industrial operations.

At the 138th Canton Fair in 2025, the spotlight on

carbon steel ball valves highlighted

remarkable technological breakthroughs that are transforming valve manufacturing processes.

Innovations in materials science and engineering techniques have led to the development of

lighter, more durable carbon steel alloys. These advances not only enhance the performance

and longevity of valves in various industrial applications but also address concerns related

to weight and transportation efficiency.

Moreover, the implementation of automated manufacturing processes has revolutionized how valve

components are produced. Advanced robotics and 3D printing technologies allow for precise fabrication,

reducing waste and improving production efficiency. Such innovations enable manufacturers to

lower costs while maintaining high standards of quality control.

As industry leaders gather to showcase these advancements, the focus on enhancing efficiency

in valve manufacturing is poised to drive significant changes in the global market landscape.

At the upcoming 138th Canton Fair in 2025, the focus on sustainability in carbon steel valve production highlights significant industry shifts towards environmentally responsible practices. The integration of carbon capture utilization and storage (CCUS) technologies in industrial applications plays a crucial role in decarbonizing the production processes. Recent reviews indicate that implementing CCUS can potentially reduce carbon emissions by up to 90% in high-carbon industries, making it a key strategy for manufacturers looking to enhance their environmental credentials. This presents a transformative opportunity for carbon steel ball valve producers to adopt innovative technologies that not only lower emissions but also potentially reduce operational costs.

Moreover, the adoption of circular economy principles is becoming increasingly relevant in the production of carbon steel valves. By emphasizing material recovery and reuse, manufacturers can mitigate waste and enhance sustainability. Reports indicate that transitioning to a circular model could save industries up to $4.5 trillion annually by 2030. This aligns with global trends highlighting the importance of sustainable production processes, particularly in energy-intensive sectors. As such, embracing these practices not only addresses environmental challenges but also positions companies competitively within the market, ultimately catering to a growing demand for sustainable industrial solutions.