-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

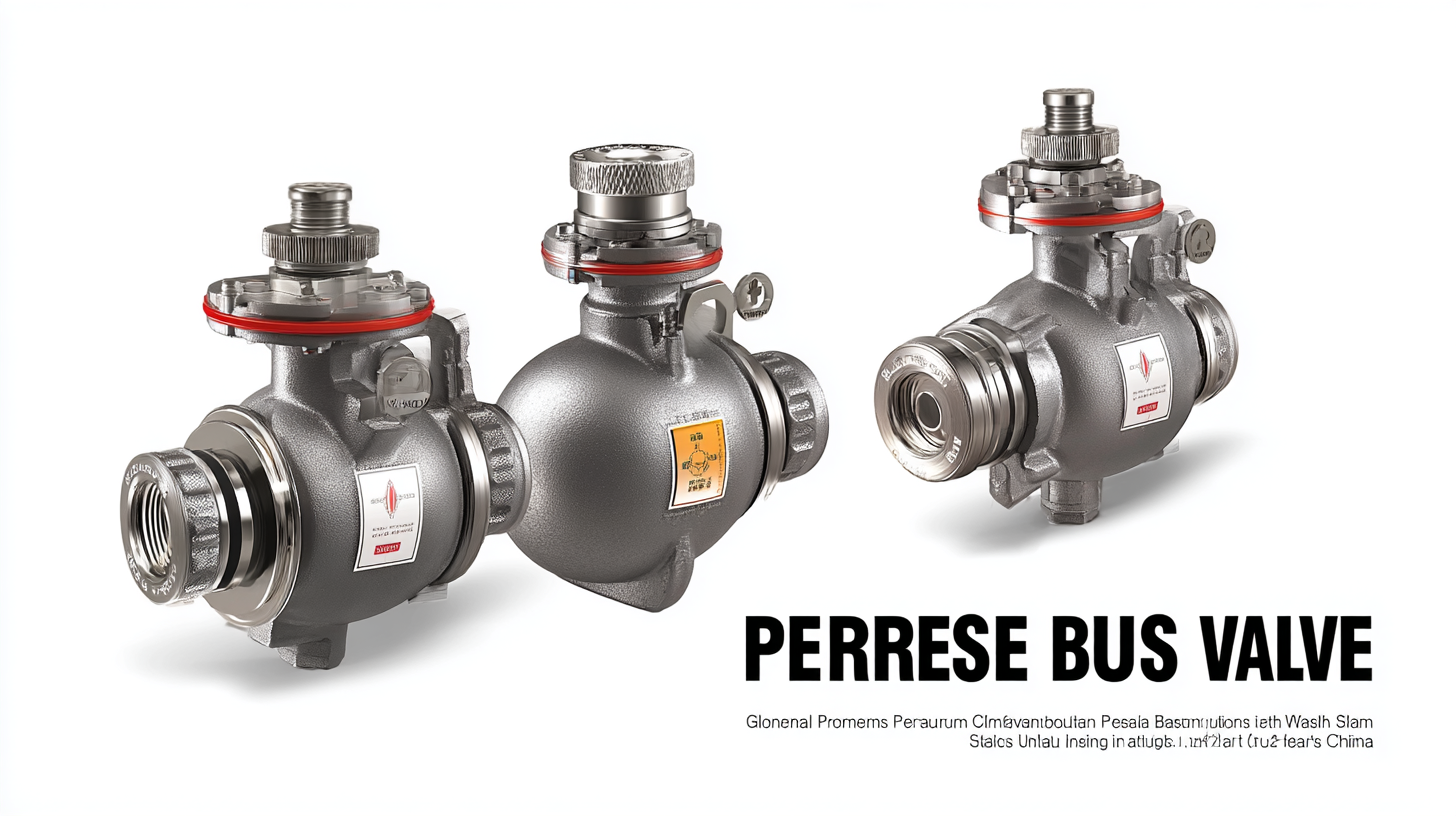

In an evolving industrial landscape where quality and reliability dictate success, the demand for high-performance components is at an all-time high. Among these essential components, the Pressure Ball Valve stands out as a critical element in various applications, ensuring optimal control in fluid dynamics. This blog delves into the fascinating journey of premium Pressure Ball Valves crafted in China, highlighting the country's significance as a global manufacturing powerhouse. With a perfect blend of advanced technology and traditional craftsmanship, Chinese manufacturers are setting new benchmarks for unmatched excellence in the valve industry. We will explore the key features that distinguish these valves, the rigorous standards upheld during production, and how their innovative design plays a pivotal role in improving efficiency and safety across diverse sectors. Join us as we uncover the uniqueness of these top-grade Pressure Ball Valves and their profound impact on global supply chains.

When sourcing high-quality pressure ball valves, China stands out as a leading manufacturer, boasting a significant share of the global market. According to a report by ResearchAndMarkets, the global ball valve market is projected to reach USD 9.78 billion by 2025, with Asia-Pacific, particularly China, accounting for a substantial portion of this growth due to its advanced manufacturing capabilities and cost-effective production.

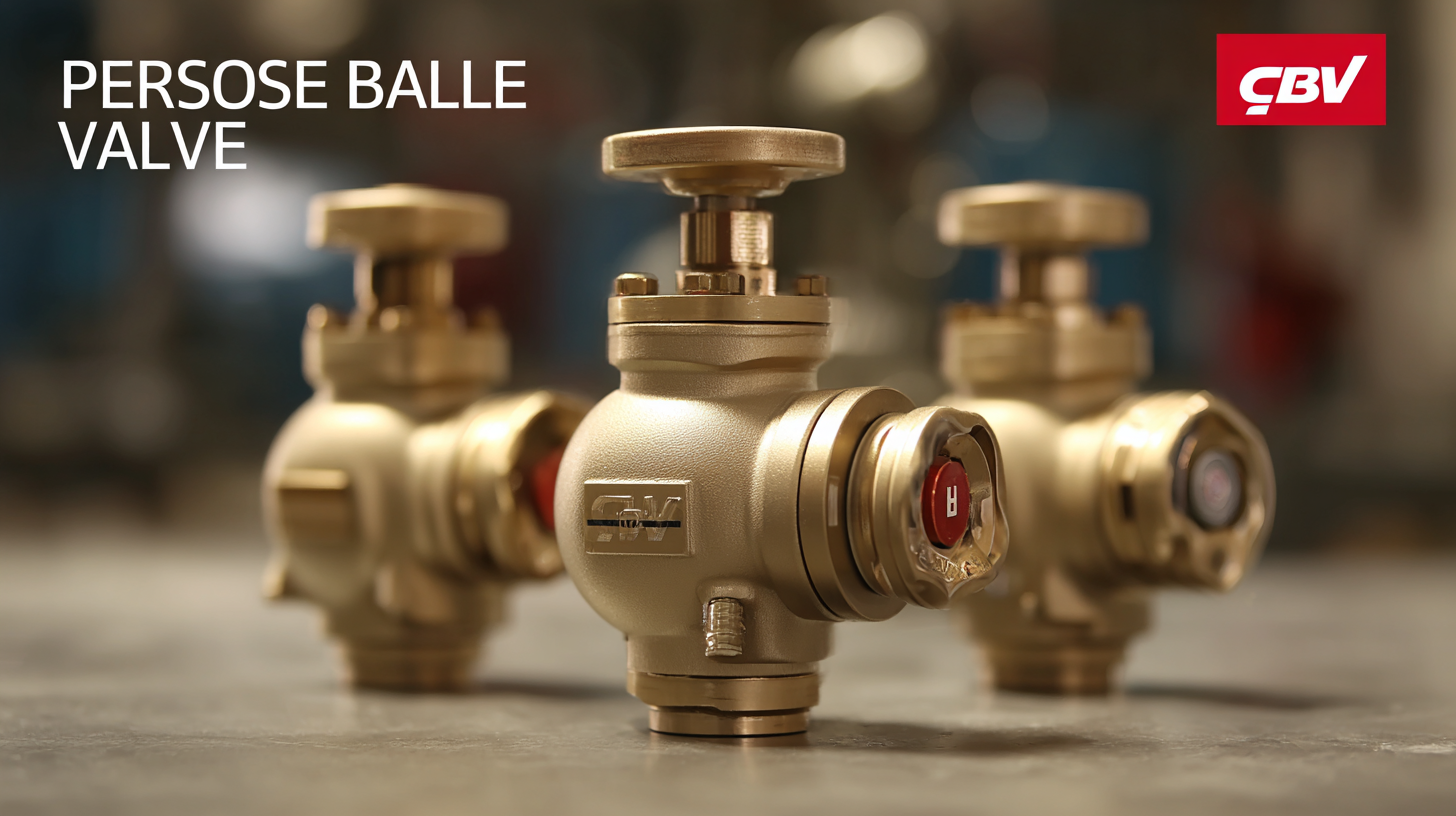

To ensure the quality of pressure ball valves sourced from China, it is crucial to implement rigorous evaluation strategies. Collaborating with suppliers who adhere to international quality standards, such as ISO 9001 and API 6D certification, can effectively mitigate risks associated with substandard products. Furthermore, leveraging platforms like Alibaba and Global Sources enables buyers to access verified manufacturers and read customer testimonials, enhancing their decision-making process.

Additionally, engaging in regular factory audits and quality inspections is vital. A study from the International Federation of Robotics indicates that automation in manufacturing is on the rise, with China leading the robotics industry. This technological advancement not only boosts efficiency but also improves the consistency and quality of production, making Chinese manufacturers a reliable choice for premium pressure ball valves.

When it comes to premium pressure ball valves, the importance of selecting reliable manufacturers cannot be overstated. In the competitive landscape of industrial components, the quality of valves plays a critical role in ensuring operational efficiency and safety. A reputable manufacturer adheres to stringent quality control measures, ensuring that every valve meets or exceeds industry standards. This commitment to excellence not only reduces the likelihood of failures and costly downtime but also enhances the overall reliability of fluid control systems.

Furthermore, partnering with established Chinese manufacturers can provide significant advantages in terms of innovation and cost-effectiveness. China has become a global hub for advanced manufacturing techniques and technology, allowing manufacturers to produce high-quality valves at competitive prices. By choosing a trustworthy manufacturer, businesses can benefit from reduced lead times and more consistent supply chains. This strategy is essential for companies looking to maintain operational efficiency while navigating the complexities of the global market. Quality assurance from a dependable source also instills confidence, enabling businesses to focus on their core competencies without worrying about the risks associated with subpar valve performance.

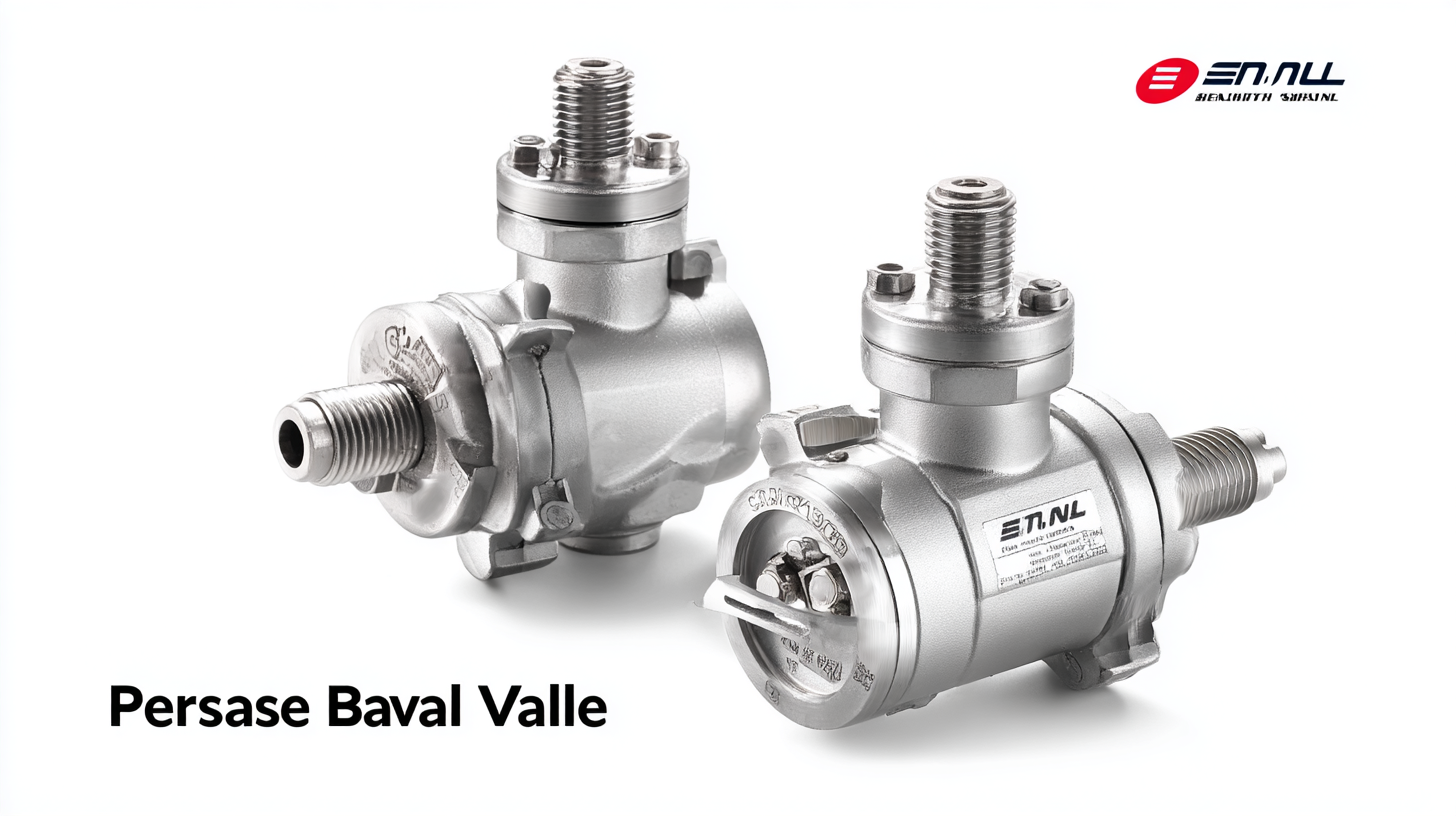

Innovative technologies are revolutionizing the production of premium pressure ball valves in China, enabling manufacturers to achieve unparalleled quality and reliability. According to a recent report by Market Research Future, the global market for ball valves is expected to reach approximately $18 billion by 2026, with a significant portion of this growth driven by advancements in manufacturing technology. Innovations such as automated machining processes, precision casting, and the integration of advanced materials have allowed Chinese manufacturers to enhance the durability and performance of their valve products, meeting the increasing demand from various industries, including oil and gas, water treatment, and chemical processing.

Moreover, the adoption of Industry 4.0 practices—leveraging IoT and smart manufacturing methodologies—has significantly optimized production efficiency in pressure ball valve manufacturing. A study by the International Journal of Production Research highlights that companies implementing these technologies have reported a reduction in production costs by up to 20%, while simultaneously improving product quality. This combination of cost efficiency and superior quality positions China as a key player in the global supply chain of premium pressure ball valves, ensuring that customers receive products that not only meet but exceed industry standards for excellence.

In today's competitive market, ensuring the quality of premium pressure ball valves is paramount for maintaining excellence in the supply chain. Best practices for quality control not only enhance product reliability but also build customer trust. Implementing a robust quality management system, conducting regular audits, and utilizing advanced technologies can significantly improve outcomes.

AI plays a transformative role in quality control by enabling data-driven decision-making. By analyzing vast amounts of production data, manufacturers can identify anomalies and trends, ultimately leading to better forecasting and quality assurance processes. This transition towards intelligent manufacturing is a crucial step in the industrial 4.0 landscape.

**Tips:** Regular training for staff on quality standards can greatly improve compliance. Additionally, integrating AI-driven analytics tools can expedite the detection of flaws in the valve production process, allowing for swift corrective actions. Lastly, fostering a culture of continuous improvement will help ensure long-term success and outstanding product quality.

| Valve Type | Material | Size (inch) | Pressure Rating (psi) | Testing Certification | Lead Time (Weeks) |

|---|---|---|---|---|---|

| Full Port Ball Valve | Stainless Steel | 2 | 1500 | API 6D | 4 |

| Trunnion Mounted Ball Valve | Carbon Steel | 4 | 1000 | ISO 9001 | 6 |

| Reduced Port Ball Valve | Brass | 1.5 | 800 | CE | 3 |

| Floating Ball Valve | PVC | 3 | 600 | TÜV | 5 |

Navigating export regulations has become increasingly complex amid the latest global trade dynamics. Recent developments, such as the release of the Draft Trade Regulations and Directions 2025, aim to streamline the processes for Authorised Dealer (AD) Banks in managing export and import transactions, significantly enhancing efficiency. This regulatory shift aligns with a broader trend in international trade, where clarity and simplicity in compliance can bolster cross-border business activities. Industry analyses indicate that smoother export protocols can lead to a projected growth of 15% in international transactions within the next two years, particularly for goods like premium pressure ball valves.

Simultaneously, nations are fortifying their export controls, particularly concerning dual-use items. China's tightening of regulations to the US illustrates a growing trend where geopolitical factors dictate trade policies, further complicating the landscape for exporters. In this context, companies must not only comply with local regulations but also remain vigilant of international laws that may affect their market strategies. Notably, the global supply chain restructuring emphasizes the need for adaptability and informed decision-making, highlighting the indispensable role of legal expertise in navigating these complexities. As trade restrictions continue to reshape market dynamics, businesses are urged to stay informed and agile in their export strategies.

This chart illustrates the export volume of premium pressure ball valves from China over the last five years. It highlights the growing demand in international markets and the importance of navigating export regulations for successful transactions.