-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the realm of industrial processes, safety and reliability are paramount. The Double Block Bleed Valve plays a crucial role in achieving this. It provides a robust method for isolating sections of piping. This valve ensures that any potential leaks are contained. It utilizes two blocking valves with a bleed valve in between. Such a design enhances safety during maintenance. Operators can work confidently, knowing the system is secure.

However, challenges exist. Not all systems utilize this technology. Some may overlook the importance of a Double Block Bleed Valve. This can lead to severe consequences. The absence of proper isolation can result in spills or even accidents. Reflection on these shortcomings is vital. Industries must evaluate their isolation practices. A missing valve can compromise safety and efficiency.

In conclusion, the Double Block Bleed Valve is essential for ensuring system integrity. It stands as a protective measure against leaks. Each facility must assess whether they are implementing this critical component. Ignoring its significance can result in dire outcomes. It's an opportunity to strive for better safety standards.

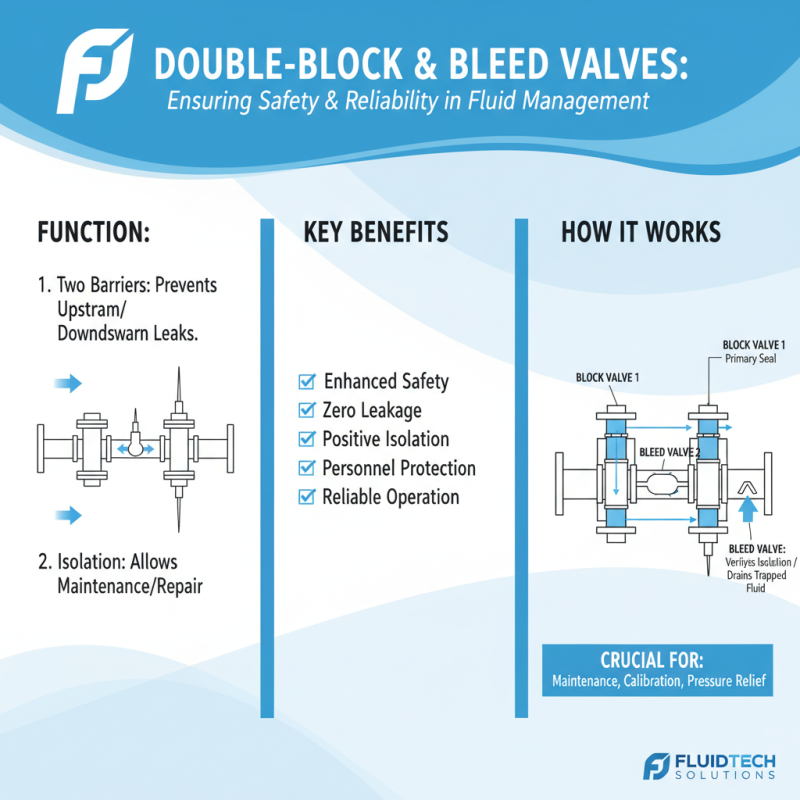

Double block and bleed (DBB) valves play a vital role in system isolation. They provide a reliable method for shutting down systems while safeguarding against leaks. The essence of a DBB valve is its design. It consists of two block valves and a bleed valve between them. This layout allows operators to ensure complete isolation from the system. If the upstream block fails, the downstream block remains intact. The bleed valve enables venting of any trapped fluid.

When safety is paramount, DBB valves become crucial. They minimize the risk of environmental hazards and system failures. For example, in a chemical processing plant, a leak can lead to disastrous consequences. The DBB setup can prevent such crises. Imagine a scenario where only one block valve exists. If it fails, the entire system could come under threat. The two blocks work as an effective backup. It’s not flawless, though. Sometimes, maintenance can be overlooked, leading to potential risks.

However, it's important to remember that DBB valves are not infallible. Regular maintenance is essential to ensure their reliability. If operators neglect this responsibility, issues may arise. Fluid may still leak if not monitored correctly. Operators must be vigilant about their systems. By understanding the importance of DBB valves, they can enhance safety and efficiency.

A Double Block Bleed Valve (DBBV) plays a vital role in system isolation. It consists of two block valves and a bleed valve in between. This setup ensures that if one block valve fails, the other can still provide a barrier. The bleed valve allows for the safe venting of trapped fluid. This feature is crucial in preventing pressure build-up.

Each component has specific functionalities. The block valves prevent flow in either direction when closed. This way, they isolate sections of the piping system under pressure. The bleed valve then checks for leaks or pressures. Operators can safely monitor system integrity without needing to cut off full operation. It's essential to inspect each part regularly. Failure to do so can lead to system failure.

A well-maintained DBBV is critical for safety and efficiency. Without it, systems may face possible leaks and hazardous situations. Implementing this valve is not just about compliance; it's about protecting personnel and the environment. Considering its design flaws or maintenance oversights can lead to unexpected challenges. Ensuring reliability requires continuous assessment and dedication.

Double block bleed valves play a crucial role in ensuring system isolation. When it comes to managing fluids, safety and reliability are paramount. These valves allow operators to effectively isolate sections of a system, which is especially important during maintenance or repair. A double block bleed valve creates two barriers, preventing leaks and protecting personnel.

One notable advantage of using these valves lies in their ability to drain any residual fluid. This minimizes the risk of accidental exposure or spills. They are designed to withstand high pressures and extreme temperatures, making them suitable for various applications. However, it’s essential to regularly inspect and maintain these valves. Neglected maintenance could lead to failures or leaks.

Another point to consider is the complexity in installation. Proper alignment is necessary to avoid unnecessary stress on the components. While double block bleed valves are highly effective, they must be installed with care. Operators should be aware of the potential pitfalls to ensure a secure isolation system. Understanding these details can ultimately lead to greater safety and efficiency.

Double block bleed valves play a critical role in various industries. In the oil and gas sector, they ensure safe isolation during maintenance. The presence of these valves minimizes risks of leaks by providing two barriers. A bleed valve allows for pressure release, adding another layer of safety. Consider the implications during a pipeline shutdown; any failure could have catastrophic results.

In chemical processing, these valves add safety during fluid transfer. They prevent cross-contamination between different substances. In pharmaceuticals, maintaining product purity is crucial. A double block bleed valve helps safeguard against unwanted mixing. Mistakes in this sector can lead to severe consequences, impacting both safety and profitability.

In water treatment, these valves help control the water flow and prevent backflow. Proper installation and maintenance are vital. Even minor lapses can lead to significant operational challenges. Industries often overlook the importance of regular checks. Reflecting on these issues can lead to improvements and ensure better system reliability.

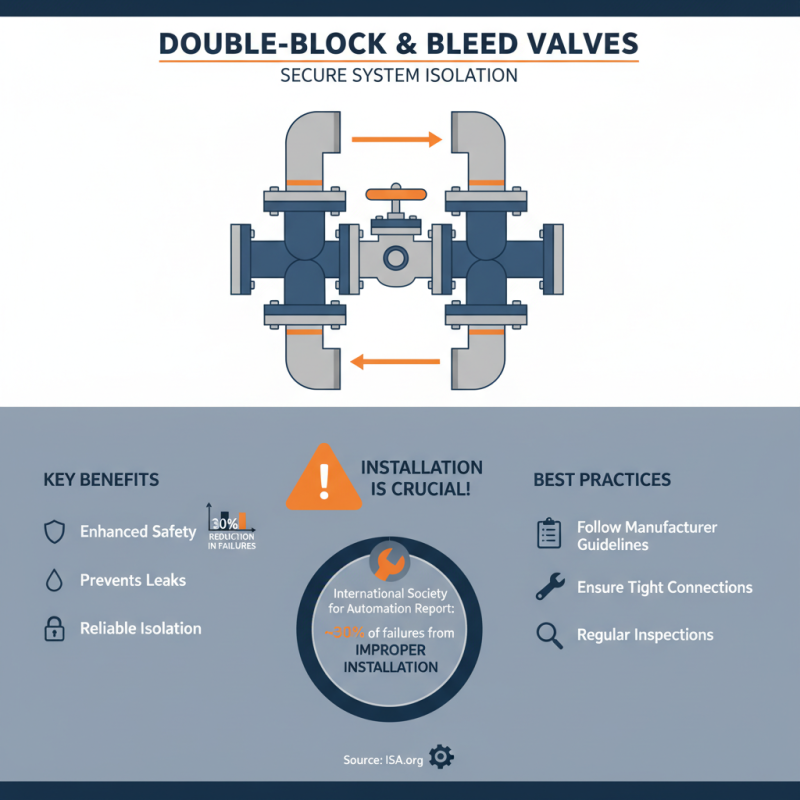

Double block bleed valves are crucial for ensuring secure system isolation in various industrial applications. Installing these valves correctly is key. According to a recent report by the International Society for Automation, improper installation accounts for nearly 30% of valve-related failures. This can lead to leaks and safety risks. Following the manufacturer's guidelines is essential. Ensure all connections are tight and inspect them regularly.

Regular maintenance is just as important. Reports indicate that 20% of valve failures stem from neglecting routine checks. A simple visual inspection can prevent larger issues down the line. Use a checklist to ensure all aspects of the valve are examined. Ensure bleed ports are free from blockages.

Training personnel on best practices is often overlooked. Many operators do not receive adequate training on these systems. This can lead to mishandling during repairs or maintenance. Investing in regular training sessions can significantly reduce the risk of human error. Safety and efficiency go hand in hand, and that should be the goal of every operation.