-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the realm of fluid control systems, the Double Ball Valve stands out as a crucial component that ensures efficient flow regulation and reliability. This innovative device consists of two ball-shaped disks positioned within the valve body, allowing for not only on/off control but also effective sealing properties. The design of the Double Ball Valve minimizes the risk of leaks, making it a favored choice in various industrial applications, including petroleum, chemical processing, and water management. Its ability to provide a tight shut-off feature and withstand high pressures further emphasizes its functionality and significance in fluid handling systems.

Understanding how a Double Ball Valve operates is essential for engineers and technicians involved in fluid control design and maintenance. The mechanism relies on the rotation of the balls, which either aligns or misaligns with the flow path, effectively controlling the passage of fluids. This operational simplicity, combined with the reliability of its design, makes the Double Ball Valve a preferred solution for applications requiring precise flow management. As industries continue to evolve, the demand for efficient and robust fluid control solutions like the Double Ball Valve remains ever-increasing, highlighting its relevance in modern engineering practices.

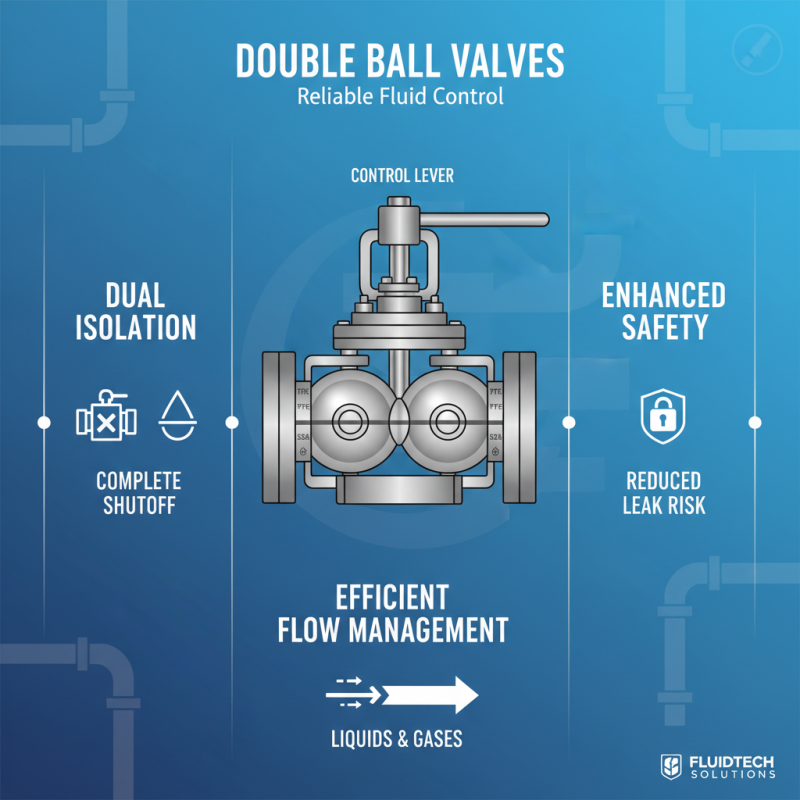

A double ball valve is a specialized valve used in fluid control systems, designed to provide enhanced reliability and safety in applications that require tight sealing and flow regulation. This type of valve consists of two independent ball mechanisms that can be operated simultaneously or individually, allowing for greater flexibility in managing fluid flows. When both balls are closed, the valve effectively seals off the flow, preventing any leakage, which is critical in situations where containment is paramount, such as in chemical processing or high-pressure applications.

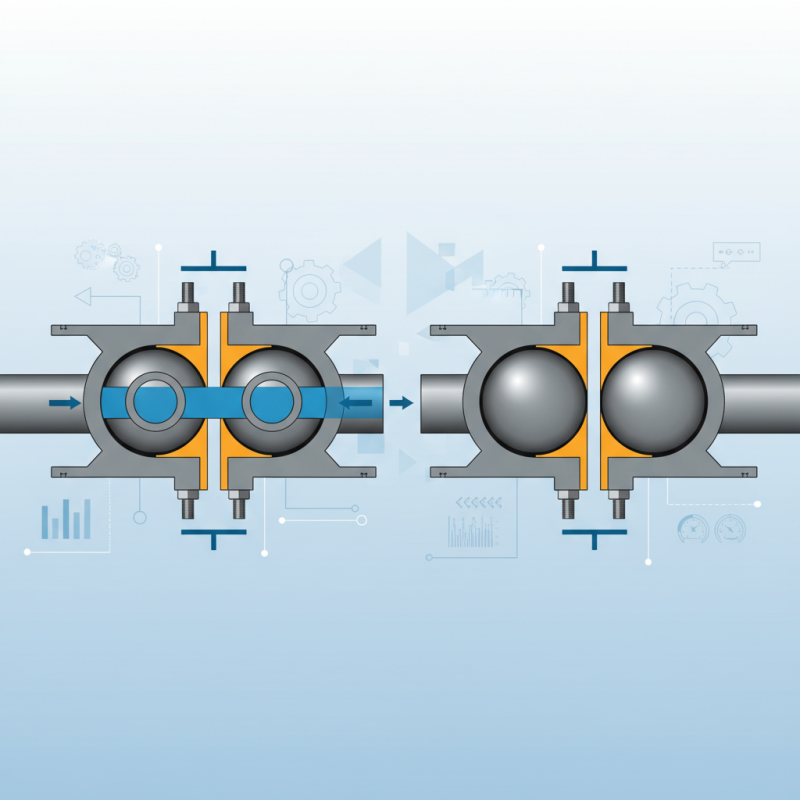

The operation of a double ball valve is straightforward. Each ball has a central hole that aligns with the pipe when the valve is open, allowing fluid to pass through. By rotating the handle or actuator, the balls can be turned to block the flow, thus controlling the fluid passage. This design not only provides robust control over high-viscosity fluids and slurries but also enables the isolation of sections of piping for maintenance without interrupting the entire system. Overall, double ball valves represent a key component in various industrial applications, owing to their effectiveness in ensuring safety and control in fluid management.

Double ball valves are designed with two independently operated balls, enabling precise control over fluid flow in a variety of applications. Each ball has a hole that aligns with the valve body's inlet and outlet ports when open, providing an unobstructed path for the fluid. When one or both balls are rotated, the flow can be either blocked or allowed to pass through. This configuration enhances reliability and ensures that even if one ball fails, the second can maintain control over the flow, which is crucial for safety in fluid management systems.

Key components of double ball valves include the valve body, the two balls, and the actuator mechanism. The valve body is typically made from durable materials that can withstand high pressures and corrosive substances. Each ball is fitted with precision seals to prevent leaks, while the actuator mechanisms can range from manual handles to automated systems, allowing for remote operation. Additionally, the design often incorporates a fail-safe feature, ensuring that the valve remains secure under pressure or in emergency situations. This robust construction and innovative design make double ball valves an essential component in industrial fluid control systems.

Double ball valves are crucial components in fluid control systems, primarily known for their efficiency in managing flow direction and pressure. These valves consist of two spherical balls that rotate within their housing, allowing for robust control over fluid passage. When one ball is in the open position, the other is closed, ensuring a tight seal is maintained when required. This design enables them to minimize leakage and prevent unintended flow, which is essential in applications where fluid integrity is critical.

The working principles of double ball valves revolve around their simple yet effective mechanical structure. As fluid pressure builds up in the system, the balls are rotated to either permit or restrict flow. This rotary motion is typically actuated either manually or through automation, making double ball valves versatile for various operational setups. The arrangement of the balls allows for quick shut-off capabilities without the need for extensive actuator power, which is particularly advantageous in emergency situations or during regular maintenance. By optimizing the flow path and enhancing sealing efficiency, double ball valves contribute significantly to the overall reliability and performance of fluid control systems.

Double ball valves are a critical component in fluid control systems, providing reliable isolation and flow management. These valves consist of two independent ball mechanisms that can be operated in tandem, allowing for efficient control over the flow of liquids or gases. The design enables operators to shut off flow completely when both balls are closed, enhancing safety and reducing the risk of leaks.

One of the significant advantages of using double ball valves is their enhanced safety profile. By requiring both balls to be closed for a complete seal, they minimize the chances of any unintentional leakages, which is particularly important in high-pressure environments. Additionally, their robust construction is suitable for a variety of applications, from industrial settings to chemical processing, ensuring durability and longevity.

**Tips for successful implementation of double ball valves include:**

- Always ensure proper installation to maintain the integrity of the system and avoid potential leaks.

- Regular maintenance checks are essential to keep these valves functioning optimally; look out for signs of wear or damage.

- Consider the specific fluid characteristics and pressure requirements to select the appropriate double ball valve for your application, ensuring compatibility and performance.

Double ball valves are versatile components employed across various industries for efficient fluid control, thanks to their robust design and reliability. These valves are commonly utilized in sectors such as oil and gas, water treatment, and chemical manufacturing. According to a recent market research report by Grand View Research, the global valve market, including double ball valves, is projected to reach USD 86.6 billion by 2025, highlighting the increasing demand for reliable fluid control mechanisms in industrial applications.

In the oil and gas industry, double ball valves play a crucial role in providing secure isolation and controlling the flow of hydrocarbons during drilling and production processes. Their ability to handle high pressure and temperature variations makes them ideal for critical applications. Similarly, in water treatment facilities, double ball valves ensure the safe and efficient transport of water by allowing for effective isolation and maintenance of pipeline systems. Additionally, the chemical industry benefits from double ball valves' resistance to corrosive substances, which is essential for handling aggressive fluids without compromising system integrity.

The versatility of double ball valves extends to HVAC and fire protection systems, where their reliability enhances operational safety. A report by MarketsandMarkets indicates that the HVAC market is expected to grow significantly, further driving the demand for efficient valve solutions. As industries continue to evolve, the role of double ball valves in fluid control will remain significant, adapting to the increasing demands for safety, efficiency, and sustainability.

| Application | Industry | Fluid Type | Operating Pressure (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| Water Treatment | Municipal | Water | 150 | 32 - 140 |

| Chemical Processing | Chemical | Acids and Bases | 200 | -20 - 200 |

| Oil and Gas Transfer | Oil & Gas | Crude Oil | 300 | -40 - 250 |

| Pharmaceutical Manufacturing | Pharmaceutical | Biologics | 150 | 32 - 170 |

| Power Generation | Energy | Steam | 600 | 0 - 400 |