-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

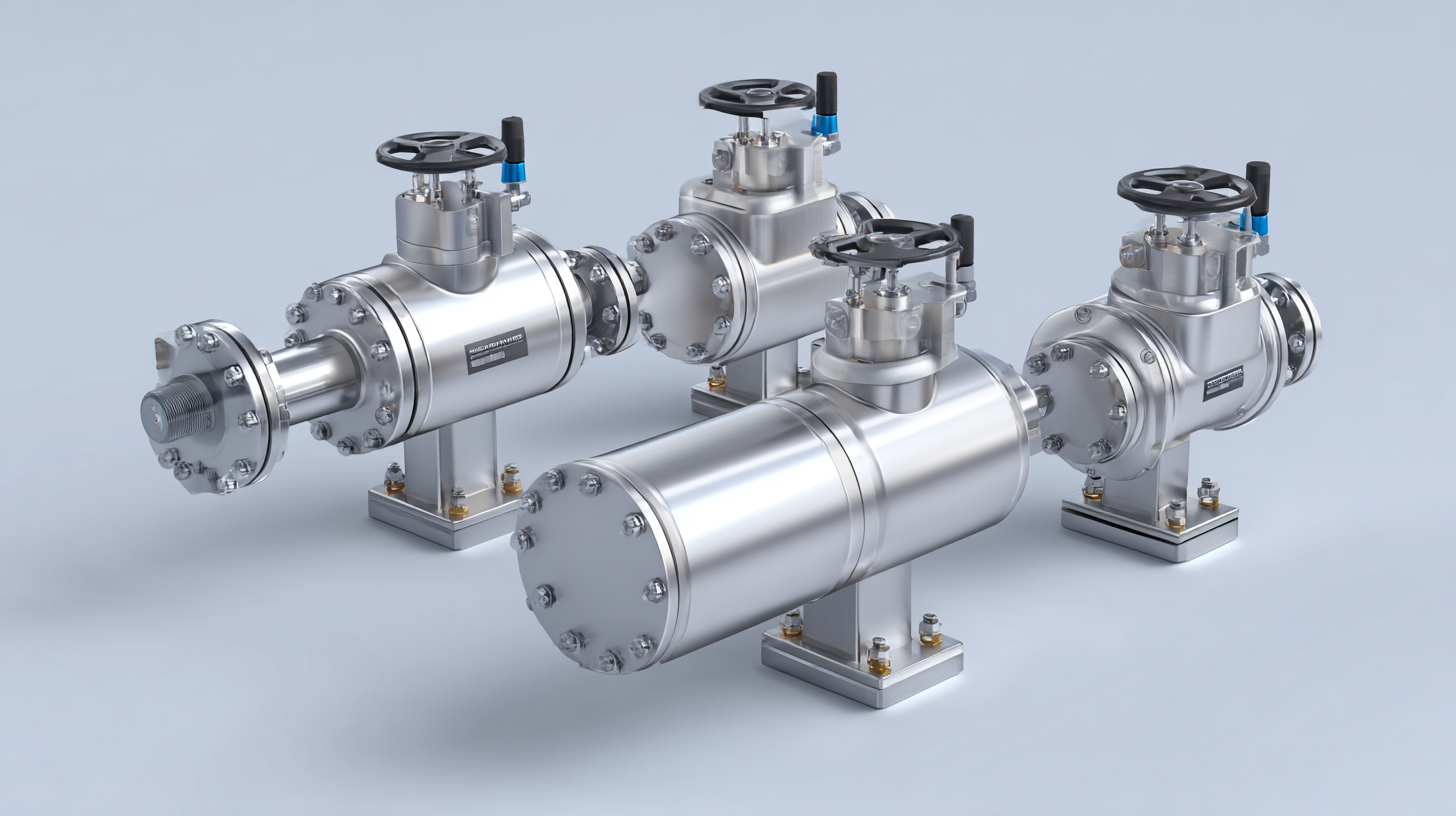

In the vast realm of industrial applications, selecting the right valve can significantly impact operational efficiency and safety. The Three Piece Ball Valve stands out as a versatile and reliable choice for various industries, effectively addressing needs for precision, durability, and ease of maintenance. This type of valve is comprised of three distinct components that allow for straightforward assembly, disassembly, and replacement, ensuring that any necessary maintenance can be conducted smoothly and with minimal downtime.

In this blog, we will explore seven compelling reasons why the Three Piece Ball Valve is a superior option for your industrial needs, highlighting its advantages in terms of adaptability to different applications, cost-effectiveness, and performance reliability. Whether you're working with liquids or gases, understanding the benefits of this valve design can empower you to make informed decisions that enhance your operational processes.

When it comes to industrial applications, three piece ball valves stand out due to their versatility and efficiency. One of the primary benefits of a three piece ball valve is its design, which allows for easy maintenance and repair. Unlike traditional valves that require complete removal from the pipeline for servicing, three piece designs can be maintained on-site.

This feature not only saves time but also reduces downtime, which is critical in maintaining smooth operations in any industrial setting.

Furthermore, three piece ball valves offer superior sealing capabilities, ensuring minimal leakage and enhanced safety. Their robust construction allows them to handle high pressures and temperatures, making them suitable for a wide range of industrial fluids. The ability to replace individual components without the need to dismantle the entire valve system also contributes to long-term cost-effectiveness, as businesses can avoid the expense of regular valve replacements.

With their combination of durability, ease of use, and reliability, three piece ball valves are an excellent choice for industries looking to optimize their fluid control systems.

When it comes to selecting the right valve for industrial applications, durability and longevity are paramount factors that can significantly impact operational efficiency. A three-piece ball valve stands out in this regard, particularly due to its robust construction and advanced materials. The enhanced durability of these valves is often attributed to their integrated design, which allows for easy maintenance and replacement of seals without removing the entire valve from the pipeline. This design feature not only minimizes downtime but also extends the lifespan of the valve itself.

Moreover, the market for PTFE-lined ball valves, a type of three-piece design, is expected to show considerable growth in the coming years. Valued at $64.14 million in 2024, the market is projected to reach $84.01 million by 2032, reflecting a compound annual growth rate (CAGR) of 3.4%. This growth underscores the increasing demand for durable and reliable valve solutions in various industrial sectors. As industries continue to prioritize efficiency and longevity, the adoption of three-piece ball valves is likely to become more prevalent, further solidifying their reputation as a top choice for industrial needs.

| Reason | Benefit | Comparison with Other Valves | Longevity |

|---|---|---|---|

| Enhanced Durability | Longer service life under harsh conditions | More resistant to wear and tear than gate valves | 5-10 years longer than conventional valves |

| Easy Maintenance | Quick disassembly for repairs | Requires less time than ball and butterfly valves | Up to 20% lower maintenance costs |

| High Pressure Handling | Suitable for high-pressure applications | Comparable to metal-seated ball valves | Reliable performance over several years |

| Versatile Design | Adaptable to various piping layouts | More flexible than standard valves | Versatility enhances lifespan |

| Tight Sealing | Prevents leakage effectively | Stronger sealing compared to globe valves | Maintains pressure integrity for years |

| Flow Efficiency | Minimizes pressure drop | More efficient than multi-turn valves | Consistent performance over time |

| Cost Efficiency | Lower overall lifecycle costs | More cost-effective than manual valves | Maximizes financial resources |

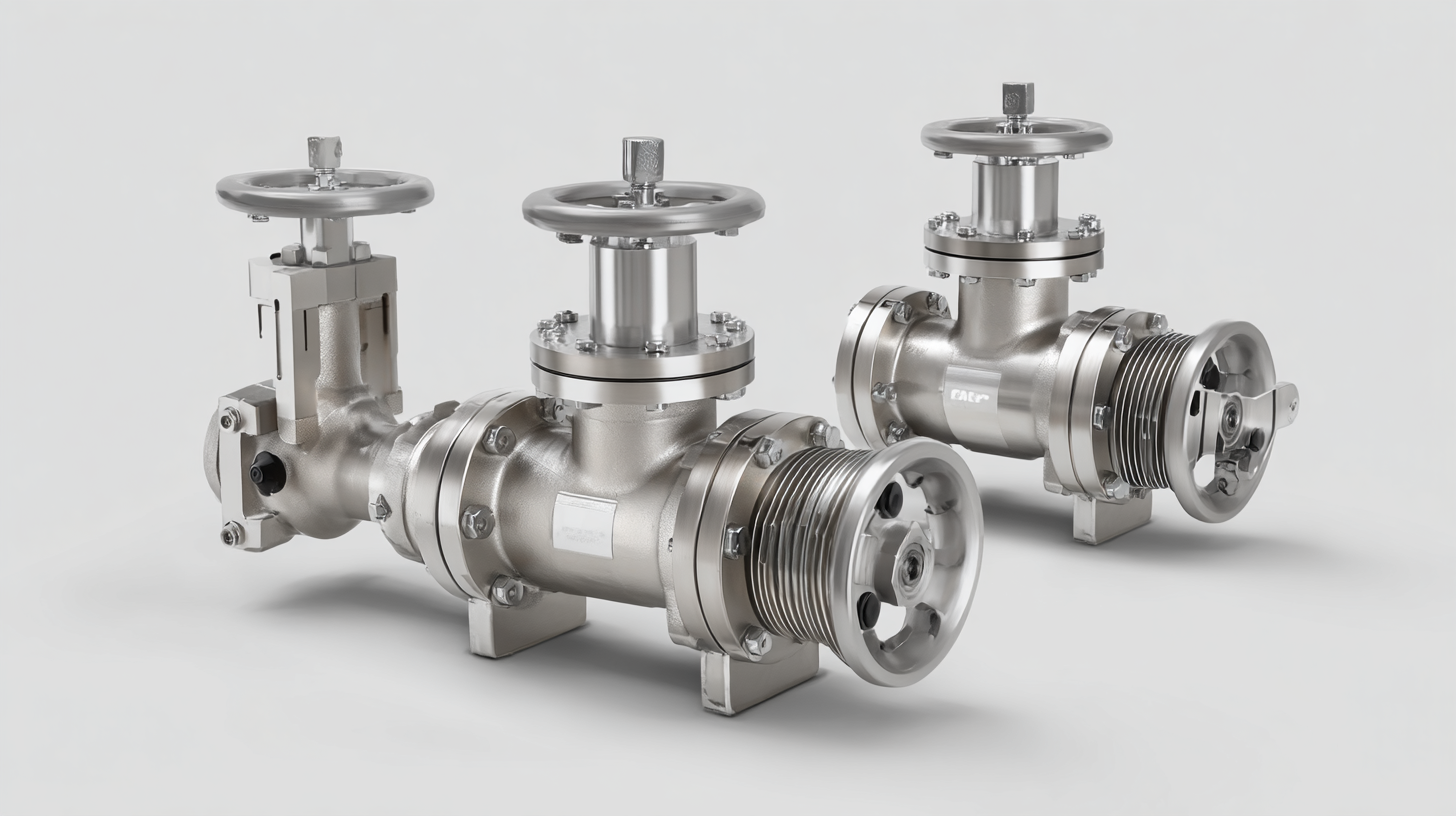

When it comes to industrial applications, the versatility of equipment can make a significant difference in efficiency and adaptability. A three-piece ball valve stands out as an ideal choice, accommodating a wide array of processes across various industries. Its modular design allows for easy installation and maintenance, enabling operators to quickly adjust configurations to suit specific operational requirements. Whether dealing with high-pressure systems, different fluid types, or varying temperatures, three-piece ball valves provide the flexibility necessary for seamless integration.

Moreover, the ability to customize these valves enhances their utility even further. Industrial processes often require precise flow control, and a three-piece ball valve can be tailored to meet specific demands, thanks to its interchangeable components. This means that businesses can adapt their flow control systems without replacing the entire assembly, saving time and resources. As industries continue to evolve, the need for adaptable and efficient solutions becomes increasingly critical, making three-piece ball valves an essential component in staying ahead of the curve.

This chart illustrates the significance of various advantages of using three-piece ball valves in industrial applications, highlighting their versatility, durability, and safety among other benefits.

When it comes to industrial applications, maintenance efficiency is paramount. A three-piece ball valve stands out as a preferred choice due to its simplified maintenance and repair features. One of the key advantages is the ability to easily access and replace the internal components without needing to dismantle the entire pipeline system. This not only reduces downtime but also minimizes labor costs, making it a cost-effective solution for facilities aiming to streamline operations.

When it comes to industrial applications, maintenance efficiency is paramount. A three-piece ball valve stands out as a preferred choice due to its simplified maintenance and repair features. One of the key advantages is the ability to easily access and replace the internal components without needing to dismantle the entire pipeline system. This not only reduces downtime but also minimizes labor costs, making it a cost-effective solution for facilities aiming to streamline operations.

Furthermore, the design of three-piece ball valves allows for easy inspection and cleaning, contributing to improved reliability and performance. In industries where precision and safety are crucial, such as oil and gas or pharmaceuticals, quick maintenance can significantly impact productivity. By opting for three-piece ball valves, businesses can ensure that their systems remain operational with minimal interruption, ultimately leading to enhanced overall efficiency and peace of mind in their industrial processes.

When it comes to fluid control solutions, cost-effectiveness is a critical factor in maximizing your investment. A three-piece ball valve stands out as an optimal choice for industrial applications due to its inherent design advantages. The modular nature of these valves allows for easy maintenance and replacement of components, which can significantly reduce downtime and repair costs. This translates into a more efficient use of resources, aligning with investment strategies that prioritize long-term returns and risk management. By investing in three-piece ball valves, industries can ensure not only the reliability of their operations but also the sustainability of their financial health.

Additionally, as industries increasingly adopt smart technologies and integrate renewable energy sources, the role of efficient fluid control systems becomes paramount. The advancements in technology echo the ongoing trends in energy storage and management, where maximizing the return on investments is key. Just as businesses are exploring ways to leverage artificial intelligence and automated solutions, the choice of valves and other components in industrial processes can influence overall efficiency. By prioritizing cost-effective solutions like three-piece ball valves, organizations can enhance their operational productivity while supporting a sustainable approach to fluid management in a rapidly changing industrial landscape.